Sep . 12, 2024 16:28 Back to list

42 Butterfly Valve - High Performance and Durability

Understanding the 42% Butterfly Valve A Key Component in Fluid Control Systems

In the world of industrial flow management, the butterfly valve stands out as an essential component in regulating the flow of liquids and gases. Among various specifications, the “42% butterfly valve” is a term that refers to a specific design or performance characteristic within the broader category of butterfly valves. In this article, we will delve into the fundamentals of butterfly valves, their applications, and the significance of the 42% design.

What Is a Butterfly Valve?

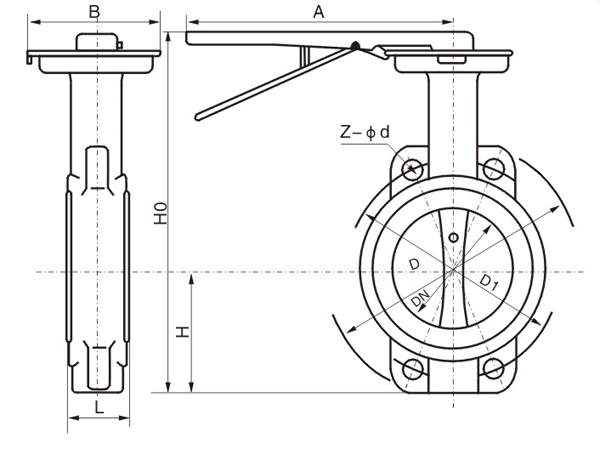

A butterfly valve is a type of quarter-turn valve that uses a rotating disc to control the flow of fluid through a pipe. The disc is mounted on a shaft, and when the valve is in the open position, the disc is parallel to the flow, allowing maximum flow rate. Conversely, when the valve is closed, the disc is perpendicular to the flow, effectively blocking it. This simple yet efficient mechanism makes butterfly valves suitable for various applications.

Components and Construction

Butterfly valves typically consist of the following components a body or casing, a disc, a shaft, and a sealing mechanism. The body can be constructed from a range of materials, including cast iron, stainless steel, and PVC, depending on the type of fluid and environmental conditions where the valve will be used. The disc is often made of metal or plastic, and the sealing mechanisms can include elastomeric seals or metal-to-metal contact, depending on the requirements for pressure and temperature performance.

Applications of Butterfly Valves

42 butterfly valve

Butterfly valves are widely used in various industries, including water treatment, HVAC systems, power generation, and chemical processing. Their ability to handle high flow rates with minimal pressure drop makes them ideal for systems that require efficient fluid control. The compact design of butterfly valves also allows for space-saving installation in pipelines, making them the preferred choice in many engineering applications.

The 42% Design Specification

The term “42% butterfly valve” often refers to the design specification related to the valve's disc size or effective opening area. Typically, this nomenclature might indicate that the valve operates efficiently at about 42% of its maximum flow capacity at specific conditions. This design ensures optimal performance and energy efficiency, making it a suitable choice for applications requiring precise flow regulation.

For instance, using a butterfly valve with a 42% opening allows for controlled flow rates in cooling systems, where excessive flow could lead to inefficiencies and system failures. Additionally, the 42% design may provide advantages in terms of cavitation resistance, reducing wear and tear on components over time.

Conclusion

The 42% butterfly valve serves as an important piece of technology in fluid control systems across various industries. Its design allows for effective and efficient regulation of flow, ensuring that processes are optimized while maintaining reliability. Understanding the specifics of this valve and its applications can lead to better system designs and improved operational performance. Whether in water treatment, chemical processing, or HVAC systems, the butterfly valve continues to hold a pivotal role in fluid dynamics, showcasing the importance of engineering innovations in industrial applications.

-

Thread Micrometer Set FeaturesNewsJul.04,2025

-

Right Angle Ruler Tool for WoodworkingNewsJul.04,2025

-

Precision Frame Level Calibration StepsNewsJul.04,2025

-

Magnetic Vee Block MaterialsNewsJul.04,2025

-

Heavy Duty Ground Anchors in MiningNewsJul.04,2025

-

Features of Welding Table Cast IronNewsJul.04,2025

Related PRODUCTS