Jun . 25, 2024 07:39 Back to list

400mm Butterfly Valve Fluid Control Solution for Industrial Pipelines

An Insight into 400mm Butterfly Valves Key Features and Applications

In the realm of industrial fluid control systems, valves play an instrumental role in regulating, directing, or stopping the flow of various media, including liquids, gases, and slurries. Among these valves, the butterfly valve stands out for its simplicity, efficiency, and versatility. This article delves into the specifics of the 400mm butterfly valve, exploring its design, operational mechanisms, and the myriad of applications it serves across different industries.

**Understanding the Design of 400mm Butterfly Valves**

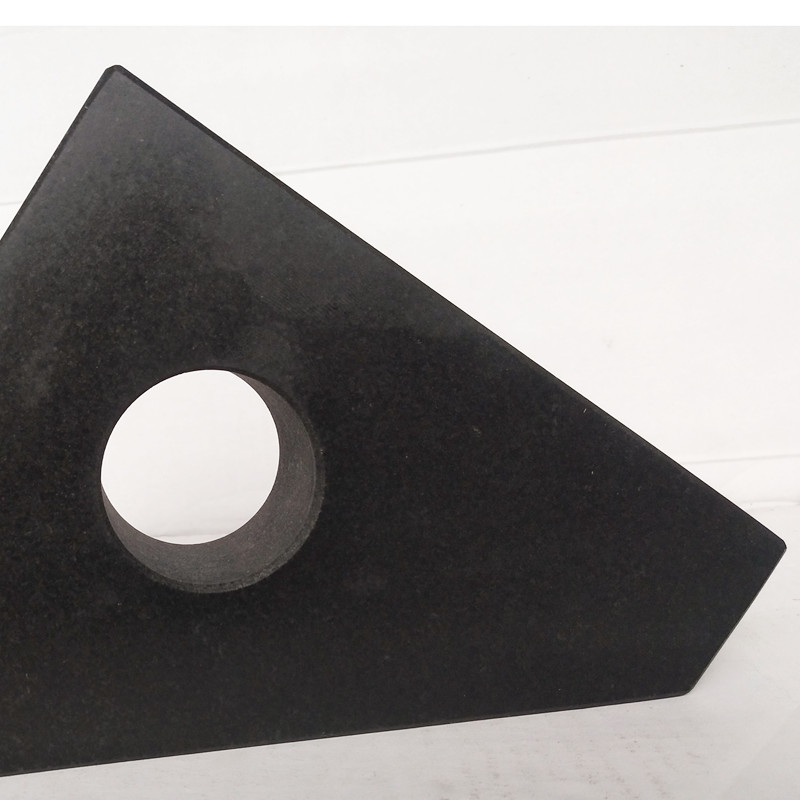

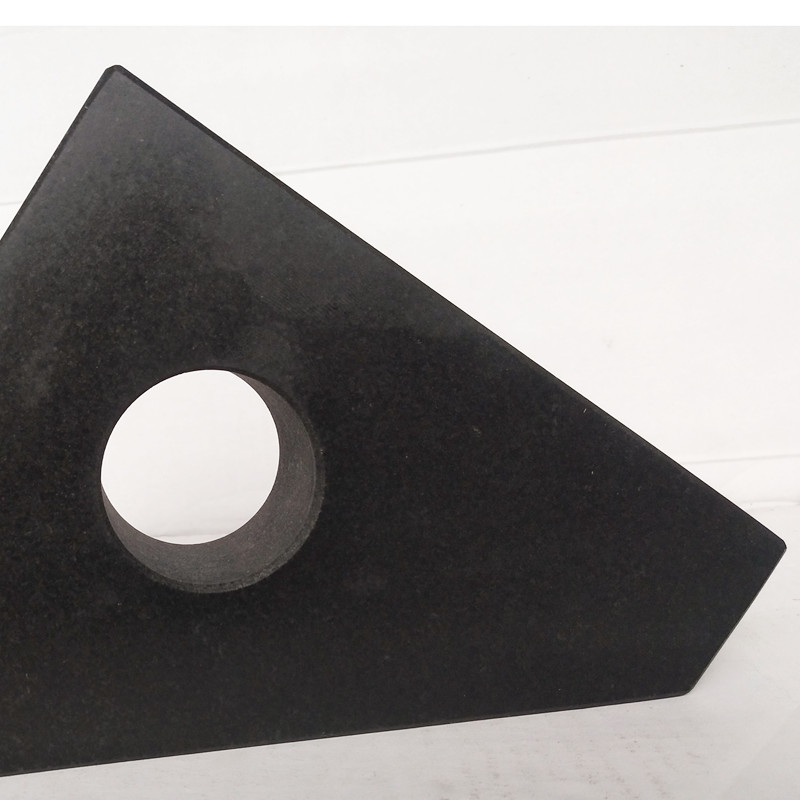

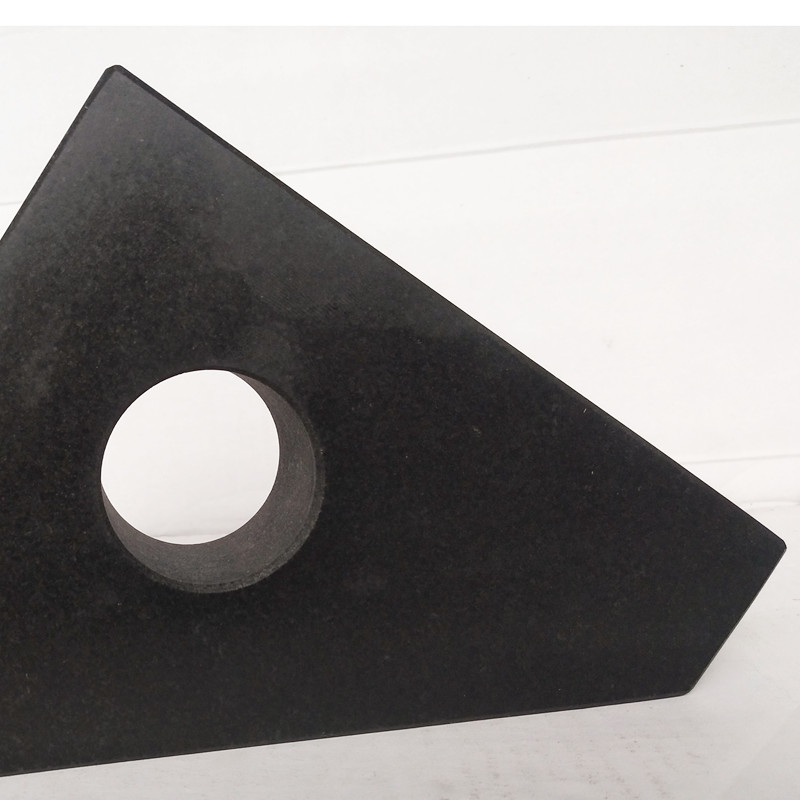

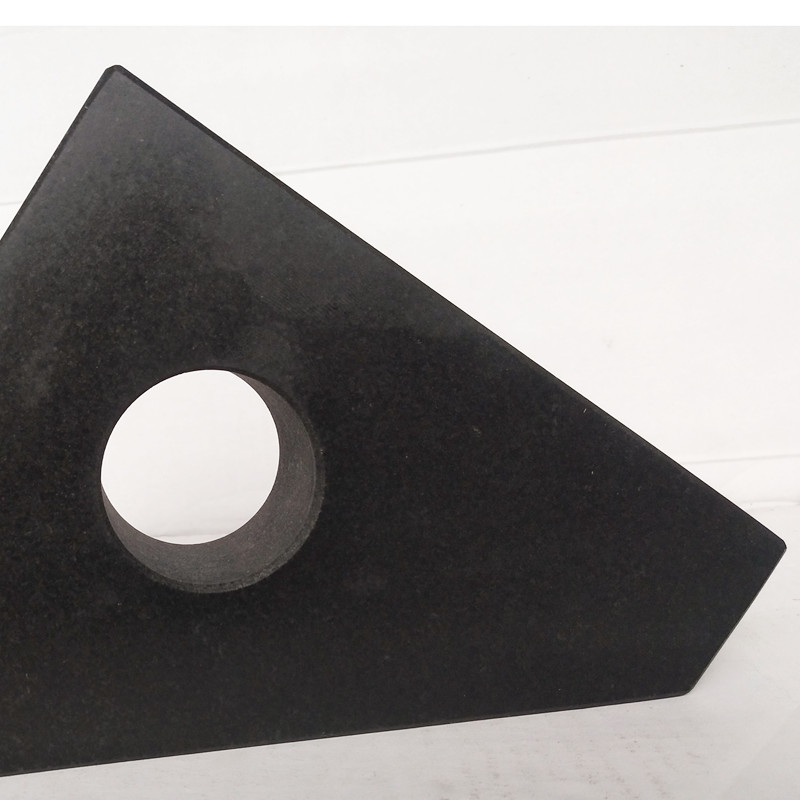

A 400mm butterfly valve refers to a valve with a nominal diameter of 400 millimeters, which translates to a considerable size suitable for handling substantial flow rates. The key component of this valve is a disc, positioned perpendicular to the flow within the pipe, functioning as the valve's closing mechanism. This disc, typically made from materials like stainless steel, aluminum, or rubber-coated metals to ensure durability and resistance against corrosion and abrasion, rotates on a shaft that passes through the valve's bore.

The valve operation is achieved through a lever, gear, or actuator (manual, electric, or pneumatic) mounted externally, allowing the disc to rotate a quarter turn (90 degrees). In the open position, the disc aligns with the valve body's bore, presenting minimal resistance to flow. Conversely, when rotated to the closed position, the disc blocks the bore, effectively halting the flow.

**Key Features and Benefits**

One of the primary advantages of 400mm butterfly valves is their compact design, which makes them space-efficient compared to other types of valves of similar flow capacity. This feature is particularly beneficial in installations where space is at a premium. Moreover, they offer relatively low-pressure loss, ensuring efficient flow dynamics and energy savings.

Another advantage lies in their ease of maintenance

Another advantage lies in their ease of maintenance Another advantage lies in their ease of maintenance

Another advantage lies in their ease of maintenance

Another advantage lies in their ease of maintenance

Another advantage lies in their ease of maintenance 400mm butterfly valve. With fewer moving parts than many other valve types, butterfly valves are less prone to failure and are easier and quicker to repair or replace. They also allow for quick shut-off, making them suitable for emergency shutdown situations.

**Applications Across Industries**

The versatility of 400mm butterfly valves finds expression in a broad spectrum of industries

- **Water Treatment & Distribution** These valves are widely used in water treatment plants and distribution networks due to their ability to handle large volumes of water efficiently and their resilience against corrosion.

- **Petrochemical Industry** In oil refineries and petrochemical plants, they regulate and isolate flows of various process fluids, often under high-pressure conditions, demonstrating their robustness and reliability.

- **Food & Beverage** Sanitary versions, featuring FDA-approved materials and smooth surfaces for easy cleaning, are employed to maintain hygiene standards while controlling the flow of liquids and gases.

- **Power Generation** In power plants, butterfly valves manage cooling water systems, steam flows, and other critical processes, contributing to the overall operational efficiency.

- **Wastewater Management** Their ability to handle abrasive and corrosive materials makes them ideal for controlling sewage and industrial effluent flows in wastewater treatment facilities.

**Conclusion**

The 400mm butterfly valve is a testament to engineering ingenuity, offering a balance of functionality, cost-effectiveness, and adaptability across diverse industrial environments. Its straightforward design, combined with advanced actuation options, ensures precise control and reliability, making it a preferred choice for managing substantial fluid flows. As technology advances, we can expect further enhancements in material sciences and control systems to further refine the performance and longevity of these vital components in industrial infrastructure.

400mm butterfly valve. With fewer moving parts than many other valve types, butterfly valves are less prone to failure and are easier and quicker to repair or replace. They also allow for quick shut-off, making them suitable for emergency shutdown situations.

**Applications Across Industries**

The versatility of 400mm butterfly valves finds expression in a broad spectrum of industries

- **Water Treatment & Distribution** These valves are widely used in water treatment plants and distribution networks due to their ability to handle large volumes of water efficiently and their resilience against corrosion.

- **Petrochemical Industry** In oil refineries and petrochemical plants, they regulate and isolate flows of various process fluids, often under high-pressure conditions, demonstrating their robustness and reliability.

- **Food & Beverage** Sanitary versions, featuring FDA-approved materials and smooth surfaces for easy cleaning, are employed to maintain hygiene standards while controlling the flow of liquids and gases.

- **Power Generation** In power plants, butterfly valves manage cooling water systems, steam flows, and other critical processes, contributing to the overall operational efficiency.

- **Wastewater Management** Their ability to handle abrasive and corrosive materials makes them ideal for controlling sewage and industrial effluent flows in wastewater treatment facilities.

**Conclusion**

The 400mm butterfly valve is a testament to engineering ingenuity, offering a balance of functionality, cost-effectiveness, and adaptability across diverse industrial environments. Its straightforward design, combined with advanced actuation options, ensures precise control and reliability, making it a preferred choice for managing substantial fluid flows. As technology advances, we can expect further enhancements in material sciences and control systems to further refine the performance and longevity of these vital components in industrial infrastructure.

Another advantage lies in their ease of maintenance

Another advantage lies in their ease of maintenance

Another advantage lies in their ease of maintenance

Another advantage lies in their ease of maintenance 400mm butterfly valve. With fewer moving parts than many other valve types, butterfly valves are less prone to failure and are easier and quicker to repair or replace. They also allow for quick shut-off, making them suitable for emergency shutdown situations.

**Applications Across Industries**

The versatility of 400mm butterfly valves finds expression in a broad spectrum of industries

- **Water Treatment & Distribution** These valves are widely used in water treatment plants and distribution networks due to their ability to handle large volumes of water efficiently and their resilience against corrosion.

- **Petrochemical Industry** In oil refineries and petrochemical plants, they regulate and isolate flows of various process fluids, often under high-pressure conditions, demonstrating their robustness and reliability.

- **Food & Beverage** Sanitary versions, featuring FDA-approved materials and smooth surfaces for easy cleaning, are employed to maintain hygiene standards while controlling the flow of liquids and gases.

- **Power Generation** In power plants, butterfly valves manage cooling water systems, steam flows, and other critical processes, contributing to the overall operational efficiency.

- **Wastewater Management** Their ability to handle abrasive and corrosive materials makes them ideal for controlling sewage and industrial effluent flows in wastewater treatment facilities.

**Conclusion**

The 400mm butterfly valve is a testament to engineering ingenuity, offering a balance of functionality, cost-effectiveness, and adaptability across diverse industrial environments. Its straightforward design, combined with advanced actuation options, ensures precise control and reliability, making it a preferred choice for managing substantial fluid flows. As technology advances, we can expect further enhancements in material sciences and control systems to further refine the performance and longevity of these vital components in industrial infrastructure.

400mm butterfly valve. With fewer moving parts than many other valve types, butterfly valves are less prone to failure and are easier and quicker to repair or replace. They also allow for quick shut-off, making them suitable for emergency shutdown situations.

**Applications Across Industries**

The versatility of 400mm butterfly valves finds expression in a broad spectrum of industries

- **Water Treatment & Distribution** These valves are widely used in water treatment plants and distribution networks due to their ability to handle large volumes of water efficiently and their resilience against corrosion.

- **Petrochemical Industry** In oil refineries and petrochemical plants, they regulate and isolate flows of various process fluids, often under high-pressure conditions, demonstrating their robustness and reliability.

- **Food & Beverage** Sanitary versions, featuring FDA-approved materials and smooth surfaces for easy cleaning, are employed to maintain hygiene standards while controlling the flow of liquids and gases.

- **Power Generation** In power plants, butterfly valves manage cooling water systems, steam flows, and other critical processes, contributing to the overall operational efficiency.

- **Wastewater Management** Their ability to handle abrasive and corrosive materials makes them ideal for controlling sewage and industrial effluent flows in wastewater treatment facilities.

**Conclusion**

The 400mm butterfly valve is a testament to engineering ingenuity, offering a balance of functionality, cost-effectiveness, and adaptability across diverse industrial environments. Its straightforward design, combined with advanced actuation options, ensures precise control and reliability, making it a preferred choice for managing substantial fluid flows. As technology advances, we can expect further enhancements in material sciences and control systems to further refine the performance and longevity of these vital components in industrial infrastructure.

Latest news

-

Why Metric Trapezoidal Thread is Ideal for Precision Motion ControlNewsAug.05,2025

-

The Unique Properties of a Block of Granite for Industrial UseNewsAug.05,2025

-

The Role of Flanged Y Strainers in Preventing Pipeline ClogsNewsAug.05,2025

-

The Importance of Regular Calibration for Master Ring GagesNewsAug.05,2025

-

How a Cast Iron Surface Table Enhances Accuracy in ManufacturingNewsAug.05,2025

-

Comparing Different Check Valve Types for Optimal Flow ControlNewsAug.05,2025

Related PRODUCTS