Nov . 25, 2024 19:32 Back to list

4000 Check Valve Performance and Applications in Fluid Control Systems

Understanding the 4000% Check Valve Function, Benefits, and Applications

In various industrial applications, maintaining fluid control and preventing backflow is crucial for safety and efficiency. One of the key components designed to achieve this is the check valve. Among the various types available, the 4000% check valve has garnered attention for its unique features and capabilities. This article will explore the characteristics, benefits, and applications of the 4000% check valve, highlighting its significance in modern fluid management systems.

What is a Check Valve?

A check valve, also known as a non-return valve, is a mechanical device that allows fluid to flow in one direction only. The primary function of a check valve is to prevent the reverse flow of liquids or gases, ensuring that the system operates effectively and safely. Check valves come in various designs, including spring-loaded, ball, and diaphragm types, each suitable for different applications and operational requirements.

Characteristics of the 4000% Check Valve

The designation 4000% typically refers to the pressure rating or the flow capacity of the valve, indicating its ability to handle significant pressure differentials and flow rates. This feature makes the 4000% check valve ideal for high-demand applications, such as pumps, pipelines, and fluid transfer systems.

These valves are designed to withstand extreme conditions, including high temperatures and corrosive environments, due to the materials used in their construction. Common materials include stainless steel, PVC, and various alloys, which provide durability and longevity.

Benefits of Using a 4000% Check Valve

1. Enhanced Reliability The primary advantage of a 4000% check valve is its reliability in preventing backflow. By ensuring that fluids move in a single direction, these valves protect equipment from potential damage and maintain system integrity.

2. Increased Efficiency With the ability to handle high pressure and flow rates, the 4000% check valve improves overall system efficiency. This optimization minimizes energy loss and reduces wear and tear on pumps and other components.

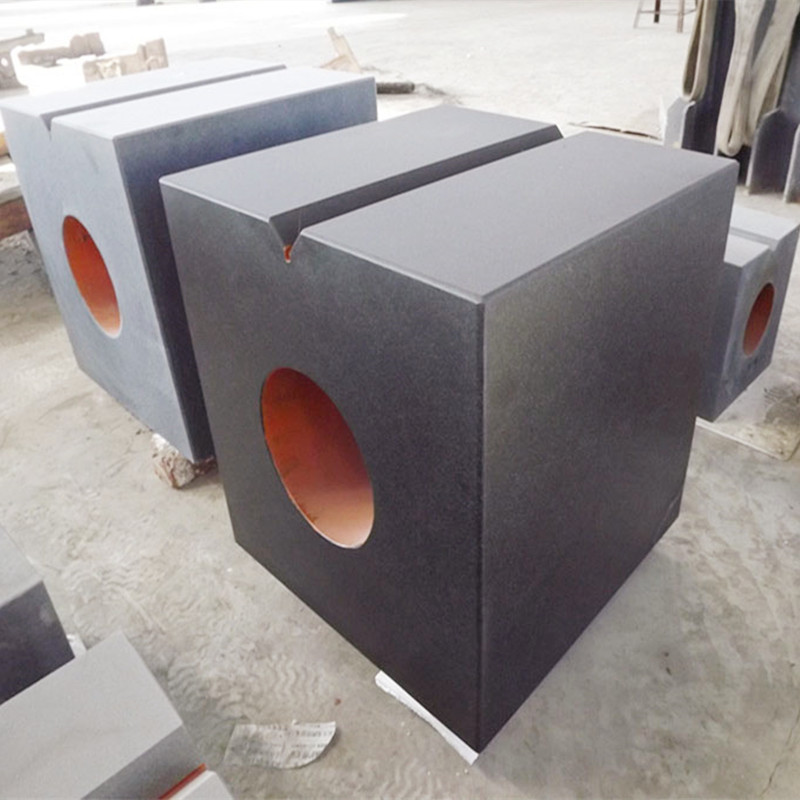

4000 check valve

3. Versatility The 4000% check valve can be utilized in various applications across different industries, including water treatment, chemical processing, oil and gas, and HVAC systems. Its adaptability to various fluids and environments adds to its appeal.

4. Cost-Effectiveness Although the initial investment in a high-performance check valve may be higher than standard options, the long-term benefits of reduced maintenance costs and extended equipment life often outweigh the upfront expenses.

Applications of the 4000% Check Valve

The 4000% check valve is commonly found in several critical applications

- Water and Wastewater Management These valves are used in treatment plants and distribution systems to ensure unidirectional flow and protect pumps and tanks. - Chemical Processing In industries dealing with corrosive materials, the durability of the 4000% check valve is essential to maintain safe operations.

- Oil and Gas Industry Check valves in this sector play a crucial role in pipeline systems, protecting against backflow that could lead to hazardous situations.

- HVAC Systems In heating, ventilation, and air conditioning systems, 4000% check valves help in regulating flow and maintaining system pressure.

Conclusion

The 4000% check valve is a vital component for fluid control in various industrial applications. Its ability to handle high pressures, prevent backflow, and adapt to diverse environments makes it an indispensable tool for engineers and operators. Investing in such advanced check valves ensures enhanced system reliability, efficiency, and safety in fluid management, contributing to improved operational outcomes across multiple sectors. Whether in water treatment, chemical processing, or HVAC systems, the 4000% check valve stands out as a robust solution in today's demanding industrial landscape.

-

Thread Plug Gauge Our Promise of Measurement ExcellenceNewsAug.22,2025

-

Gauge Pin Class Reflecting Quality LegacyNewsAug.22,2025

-

Check Valve Types for High Rise BuildingsNewsAug.22,2025

-

Water Control Valve for Irrigation SystemsNewsAug.22,2025

-

Gate Valve with Soft Seal TechnologyNewsAug.22,2025

-

Y Type Strainer for Oil and Gas ApplicationsNewsAug.22,2025

Related PRODUCTS