Nov . 18, 2024 17:28 Back to list

Versatile 3x4 Welding Table for Efficient Metal Fabrication and Projects

The Versatility of a 3x4 Welding Table

In any metalworking shop, the tools and work surfaces can significantly affect both the quality of work and the efficiency of operations. One of the most valuable pieces of equipment for welders is the welding table. A 3x4 welding table, in particular, offers numerous advantages that make it an ideal choice for a variety of projects.

Size and Space Efficiency

The 3x4 dimensions signify a table that is three feet by four feet, providing ample space for various welding tasks without consuming excessive shop floor area. This size strikes a perfect balance, allowing users to work on larger pieces while still being manageable in smaller workshops. The extended surface area accommodates multiple components, which is particularly beneficial for projects involving complex assemblies or when multiple welds are required simultaneously.

Sturdy Construction

Welding tables are designed to withstand high heat and heavy loads. A robust 3x4 welding table is typically crafted from high-quality steel, ensuring that it remains stable and secure during the welding process. This solid construction can bear the weight of heavy workpieces, and its surface is often treated to resist warping and damage caused by welding spatter. Such durability not only enhances safety but also contributes to the longevity of the table.

Features That Enhance Functionality

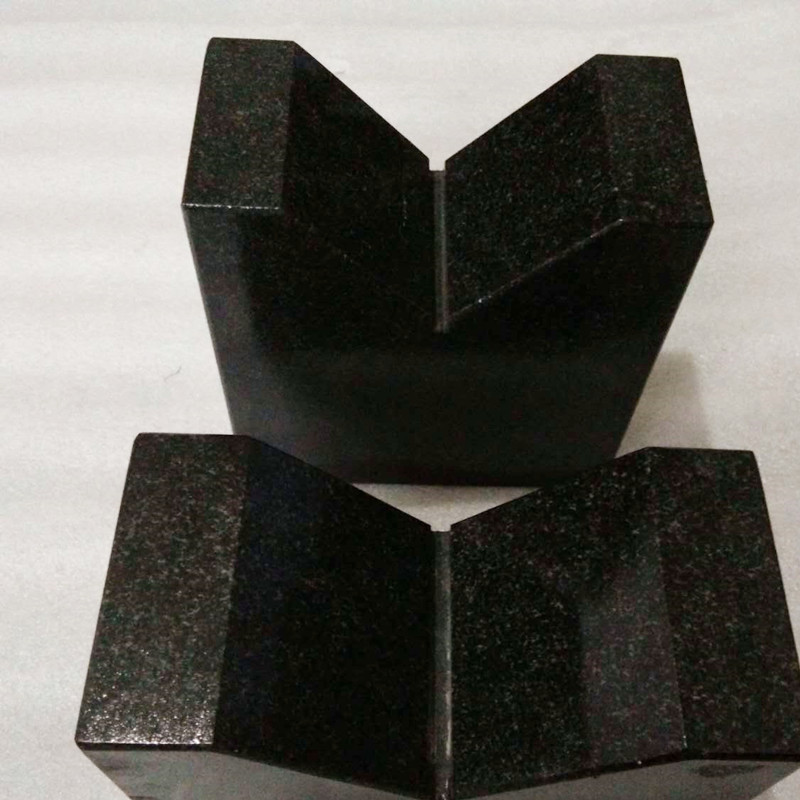

3x4 welding table

Many 3x4 welding tables come equipped with features that improve usability. Adjustable heights are an essential aspect, allowing welders to modify the surface level to suit their working posture, which can help reduce fatigue during prolonged use. Built-in clamps, dog holes, and slots offer versatile options for securing and aligning materials. These features enable faster set-ups and greater accuracy in welding, making the process more efficient and enjoyable.

Portability and Mobility

While a 3x4 welding table provides a solid working surface, portability is also a consideration for many welders. Many models come with optional wheels, allowing for easy maneuverability around the shop. This adaptability is beneficial for those who work on various projects or need to relocate their workspace often. A mobile welding table can be moved to accommodate larger items or rearranged according to workflow needs, enhancing the overall efficiency of the workspace.

Enhancing Precision and Quality

One of the most critical aspects of welding is precision. A well-constructed 3x4 welding table allows for greater accuracy in alignments and measurements. Many tables include visual aids like grids or etched measurements on their surfaces, helping welders achieve exact placements. The ability to work on a flat, leveled surface ensures that components fit together correctly, ultimately improving the quality of the finished product.

Conclusion

In summary, a 3x4 welding table is an indispensable asset for both professional and amateur welders. Its balanced dimensions provide ample workspace while maintaining portability and ease of storage. The sturdy build quality, combined with functional features, makes it a reliable platform for a wide range of welding tasks. Whether you are constructing frames, repairing machinery, or fabricating customized parts, investing in a solid welding table can significantly enhance your productivity and the quality of your work. Whether you're setting up a new workshop or looking to optimize your current space, a 3x4 welding table is a wise choice that delivers exceptional value and versatility.

-

Why Metric Trapezoidal Thread is Ideal for Precision Motion ControlNewsAug.05,2025

-

The Unique Properties of a Block of Granite for Industrial UseNewsAug.05,2025

-

The Role of Flanged Y Strainers in Preventing Pipeline ClogsNewsAug.05,2025

-

The Importance of Regular Calibration for Master Ring GagesNewsAug.05,2025

-

How a Cast Iron Surface Table Enhances Accuracy in ManufacturingNewsAug.05,2025

-

Comparing Different Check Valve Types for Optimal Flow ControlNewsAug.05,2025

Related PRODUCTS