Nov . 09, 2024 02:28 Back to list

Three Common Varieties of Check Valves and Their Applications

Understanding the Three Types of Check Valves

Check valves are essential components in many fluid handling systems, designed to allow fluid to flow in only one direction while preventing backflow. This function is critical in maintaining system efficiency and safety across various applications, including water supply, wastewater management, and industrial processes. There are several types of check valves, but the three most common types are swing check valves, lift check valves, and diaphragm check valves. This article will explore these three types of check valves, their mechanisms, advantages, and typical applications.

Swing check valves operate on a simple principle, using a hinged disc that swings open to allow fluid flow in the forward direction and closes against a seat to prevent reverse flow. The disc is typically positioned in the valve body, and as fluid flows through, the increased pressure pushes the disc open. When the fluid stops flowing or attempts to backflow, gravity and the pressure from the upstream side cause the disc to close tightly against the seat.

One significant advantage of swing check valves is their low pressure drop when in the open position, making them highly efficient for large-diameter pipelines and high-flow applications. They are most commonly used in water treatment plants, HVAC systems, and other industrial applications. However, they may not be suitable for applications with pulsating flow or those requiring frequent cycling due to the time it takes for the disc to close completely.

2. Lift Check Valves

Lift check valves, also known as vertical check valves, use a disc that moves vertically up and down within the valve body. When fluid flows in the forward direction, the disc is lifted off its seat, allowing unrestricted flow. Conversely, if backflow occurs, the disc is forced back onto the seat, creating a seal that prevents reverse flow.

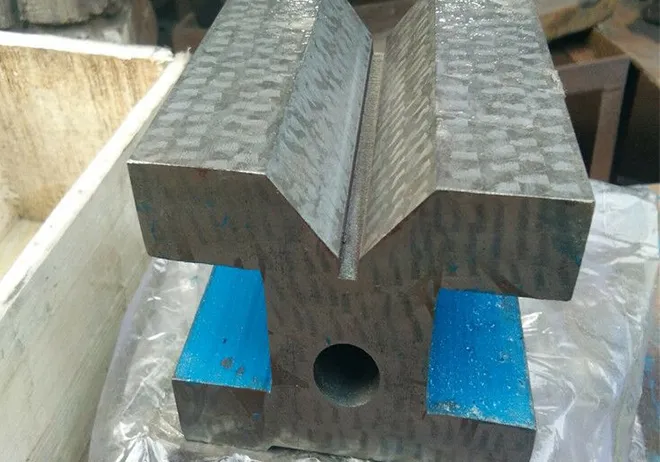

3 types of check valves

One of the primary advantages of lift check valves is their ability to function effectively in both horizontal and vertical pipelines. Additionally, they have a more compact design than swing check valves, making them easier to install in tight spaces. Lift check valves are commonly used in high-pressure applications like steam lines, boiler systems, and chemical processing due to their reliable sealing capabilities. However, they may experience a higher pressure drop than swing check valves, which should be considered in system design.

3. Diaphragm Check Valves

Diaphragm check valves utilize a flexible diaphragm instead of a traditional disc or ball. When fluid flows in the correct direction, the diaphragm flexes to allow flow. When backpressure is detected, the diaphragm seals against the valve seat, preventing any backflow. This design is particularly effective for handling viscous fluids and slurries, where traditional check valves might fail.

One significant advantage of diaphragm check valves is their ability to handle a wide variety of fluids without leaking, making them suitable for sensitive applications, including food and pharmaceutical industries. They also provide excellent sealing capabilities, which minimizes the risk of contamination. However, diaphragm check valves may have limitations regarding pressure and flow rates when compared to other types, making it essential to evaluate their suitability for specific applications.

Conclusion

In conclusion, understanding the three main types of check valves—swing, lift, and diaphragm—is crucial for selecting the right valve for a particular application. Each type has its unique advantages and limitations, which can influence their performance in various fluid handling systems. By carefully considering factors such as flow direction, pressure drop, and fluid characteristics, engineers can ensure optimal system performance and reliability, ultimately contributing to safer and more efficient processes. Whether in residential plumbing, industrial manufacturing, or municipal water treatment, the right check valve plays a vital role in the system's overall functionality.

-

Y Type Strainer Maintains System Efficiency Long TermNewsJul.15,2025

-

Valve Selection Guide for Industrial ApplicationsNewsJul.15,2025

-

Steel Fab Table Provides Durable Work Surface for WeldingNewsJul.15,2025

-

Pad Iron Provides Stable Support for Heavy MachineryNewsJul.15,2025

-

One Inch Check Valve Fits Standard Plumbing SystemsNewsJul.15,2025

-

Measuring Micrometer Ensures Precise Dimensional AccuracyNewsJul.15,2025

Related PRODUCTS