Dec . 02, 2024 00:16 Back to list

22mm Check Valve - Essential Component for Fluid Control Systems

Understanding the 22mm Check Valve A Key Component in Fluid Control Systems

In various industrial and residential applications, the control and management of fluid flow are critical to ensuring efficiency and safety. One of the essential components that facilitate this is the check valve, specifically the 22mm check valve. This article aims to explore the role of the 22mm check valve, its design, applications, and benefits in fluid control systems.

What Is a Check Valve?

A check valve, commonly referred to as a non-return valve, is a mechanical device designed to prevent backflow in a piping system. It ensures that the fluid flows in one direction while blocking reverse flow, which can be detrimental to many systems. The versatility of check valves makes them applicable in various industries including water treatment, HVAC, oil and gas, and even residential plumbing.

Design and Specifications of the 22mm Check Valve

The 22mm check valve is characterized by its diameter, which is 22 millimeters (or approximately 0.87 inches). This size makes it suitable for a variety of applications where the flow rate is controlled but not excessively high. Check valves can be made from various materials such as brass, stainless steel, PVC, and more, allowing them to be utilized in different environments, including corrosive conditions.

There are several common designs for check valves, including swing, lift, and ball check valves. The swing check valve, for instance, features a disc that swings open with the flow of fluid and closes by gravity or backflow pressure, ensuring a tight seal. The ball check valve utilizes a ball that moves to open or close the flow path as pressure changes, allowing for quick response to backflow conditions.

Applications of the 22mm Check Valve

The 22mm check valve finds its applications in various settings - Plumbing Systems In residential plumbing, 22mm check valves are commonly used under sinks, in basements, and within sump pumps to prevent backflow that could potentially contaminate clean water supplies. - Aquaculture These valves are often utilized in aquaculture systems to maintain water quality by preventing the backflow of waste contaminants. - Fire Protection Systems In fire pump systems, check valves are critical for ensuring that water reaches the required areas without reverse flow, which could hinder firefighting efforts. - HVAC Systems They play a role in heating and cooling systems by preventing backflow that could disrupt system functionality. - Irrigation Systems In agricultural applications, check valves help maintain water pressure within irrigation lines, ensuring water flows efficiently to the crops without the risk of backflow.

22mm check valve

Benefits of Using a 22mm Check Valve

The advantages of employing a 22mm check valve in fluid systems are numerous

1. Backflow Prevention The primary function of a check valve is to prevent backflow, protecting pumps, tanks, and other equipment from damage.

2. Energy Efficiency By ensuring that water flows in the intended direction without backflow, check valves help maintain system pressure, ultimately leading to energy savings.

3. System Integrity By blocking backflow, check valves help maintain the integrity of water and fluid systems, contributing to longer lifespans for pumps and pipes.

4. Easy Installation and Maintenance Many check valves, including the 22mm models, are user-friendly in terms of installation and require minimal maintenance, making them a practical choice for many applications.

Conclusion

In the realm of fluid dynamics, the 22mm check valve stands out as a small yet vital component that ensures system efficiency and integrity by preventing backflow. Its applications span residential plumbing to industrial operations, showcasing its versatility and reliability. By understanding the importance of such valves, engineers and facility managers can better design systems that are both efficient and safe, ultimately benefitting their operations and the environment. As technology continues to advance, the designs and applications of check valves will likely evolve, enhancing their performance and expanding their utility in even more fields.

-

Y Type Strainer Maintains System Efficiency Long TermNewsJul.15,2025

-

Valve Selection Guide for Industrial ApplicationsNewsJul.15,2025

-

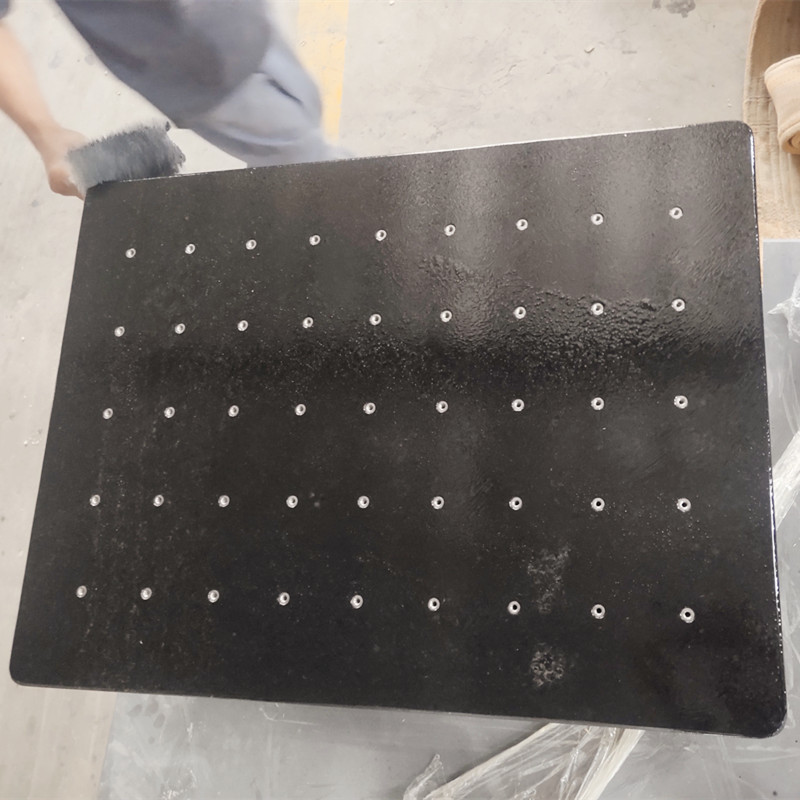

Steel Fab Table Provides Durable Work Surface for WeldingNewsJul.15,2025

-

Pad Iron Provides Stable Support for Heavy MachineryNewsJul.15,2025

-

One Inch Check Valve Fits Standard Plumbing SystemsNewsJul.15,2025

-

Measuring Micrometer Ensures Precise Dimensional AccuracyNewsJul.15,2025

Related PRODUCTS