Nov . 16, 2024 01:57 Back to list

20 gauge taper

Understanding the 20% Gauge Taper An In-Depth Analysis

The concept of 20% gauge taper is mainly discussed within the fields of engineering and manufacturing, particularly concerning materials and their processing. Tapering can significantly affect the strength and functionality of parts and products. This article explores the implications of a 20% gauge taper, including its definition, applications, benefits, and challenges.

What is Gauge Taper?

Gauge taper refers to a gradual reduction in the thickness or diameter of a material over a specified distance. In technical terms, it is often represented as a percentage reduction from the original gauge across a given length. A 20% gauge taper indicates that the material's thickness will diminish by 20% of its initial size along the designated taper length. This technique is primarily employed to improve the aerodynamics, aesthetics, and structural integrity of various components.

Applications of 20% Gauge Taper

The 20% gauge taper is widely used in industries such as aerospace, automotive, and manufacturing.

1. Aerospace Engineering In aerospace engineering, tapering aircraft wings is vital for enhancing performance. A 20% gauge taper can reduce drag and improve lift, resulting in better fuel efficiency and overall performance.

2. Automotive Design In the automotive industry, tapered components are used in exhaust systems, chassis, and body panels. A 20% taper ensures that the transitions between different parts are smooth, reducing wind resistance and noise, and ensuring better overall vehicle dynamics.

3. Manufacturing Processes Tapered components are essential in manufacturing to ensure proper fit during assembly. Whether it’s in the construction of piping systems or the creation of molds, a 20% gauge taper can facilitate the joining of parts without compromising structural integrity.

Benefits of 20% Gauge Taper

Implementing a 20% gauge taper provides several advantages

20 gauge taper

1. Weight Reduction A taper reduces the amount of material used, resulting in lightweight products that retain strength and functionality. This is particularly important in industries where weight savings are critical, such as aerospace.

2. Improved Aesthetics Tapered designs often look more streamlined and appealing. In consumer products where design is a competitive factor, the visual impact of a well-executed taper can enhance marketability.

3. Enhanced Performance In many applications, tapering can lead to improved aerodynamic or hydrodynamic properties, allowing for more efficient movement through air or fluid. Performance in applications such as piping and ducting is often optimized through careful tapering.

4. Ease of Assembly Tapered components can simplify assembly processes by ensuring that parts fit together more easily, reducing the risk of errors and the need for extensive modifications.

Challenges with 20% Gauge Taper

While the benefits are substantial, implementing a 20% gauge taper can pose challenges

1. Complex Manufacturing Creating tapered components can be more challenging than producing standard parts. Advanced manufacturing techniques, such as CNC machining or 3D printing, may be necessary to achieve the desired taper accurately.

2. Material Waste Although a taper can reduce the amount of material needed in a final product, the initial manufacturing process may result in increased waste, particularly during cutting or shaping.

3. Structural Concerns Care must be taken to ensure that the taper does not result in weakened points in the material that could cause failure under stress. Engineers must calculate the optimal taper length and angle to maintain strength.

Conclusion

The 20% gauge taper is a valuable design and manufacturing feature that offers distinct advantages across various industries. By strategically reducing material thickness, manufacturers can achieve lighter, more efficient, and aesthetically pleasing products. However, careful consideration must be given to the challenges posed by this technique, as improper implementation can negate its benefits. Understanding the intricacies of a 20% gauge taper enables engineers and designers to create innovative solutions that meet modern demands for performance and efficiency.

-

Precision Manufacturing with Advanced Spline Gauge DesignNewsJul.31,2025

-

Industrial-Grade Calibrated Pin Gauges for Exact MeasurementsNewsJul.31,2025

-

Industrial Filtration Systems Depend on Quality Filter DN50 SolutionsNewsJul.31,2025

-

High-Performance Gate Valve WholesaleNewsJul.31,2025

-

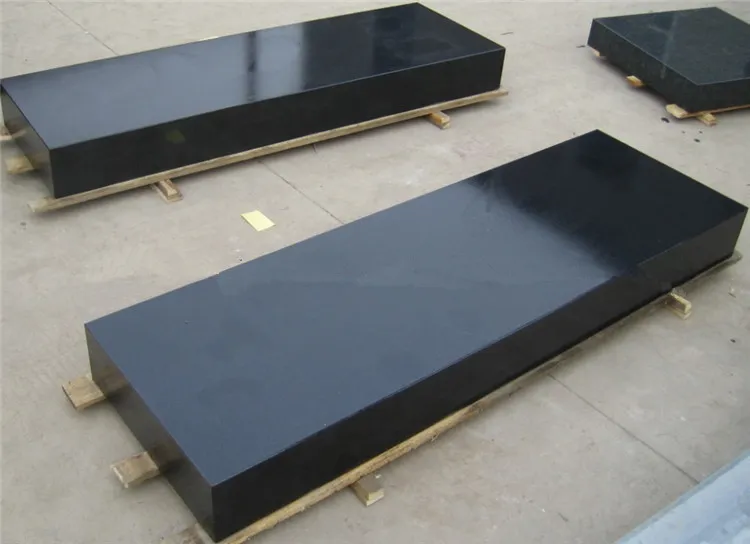

Granite Surface Plate The Ultimate Solution for Precision MeasurementNewsJul.31,2025

-

Granite Industrial Tools The Ultimate Guide for Bulk BuyersNewsJul.31,2025

Related PRODUCTS