Aug . 12, 2024 09:12 Back to list

20-inch Gate Valve Specifications and Applications for Industrial Pipeline Systems Explained

Understanding the 20-Inch Gate Valve Functionality and Applications

Gate valves are essential components in various industrial applications, particularly in waterworks, oil and gas, and manufacturing industries. Among the different sizes and types of gate valves, the 20-inch gate valve stands out due to its sizable diameter, robust design, and versatility. This article delves into the functionality, design features, applications, and maintenance of 20-inch gate valves.

Functionality of Gate Valves

A gate valve functions primarily as an on/off control device. Unlike other valve types that can throttle fluid flow, gate valves are designed to open fully or close completely, making them ideal for situations where a straight-line flow of fluid is necessary. The gate, usually a metal disc, moves up and down, enabling or blocking flow, depending on its position. When fully open, the gate valve offers minimal resistance to fluid flow, resulting in low pressure drop and efficient operation.

Design Features

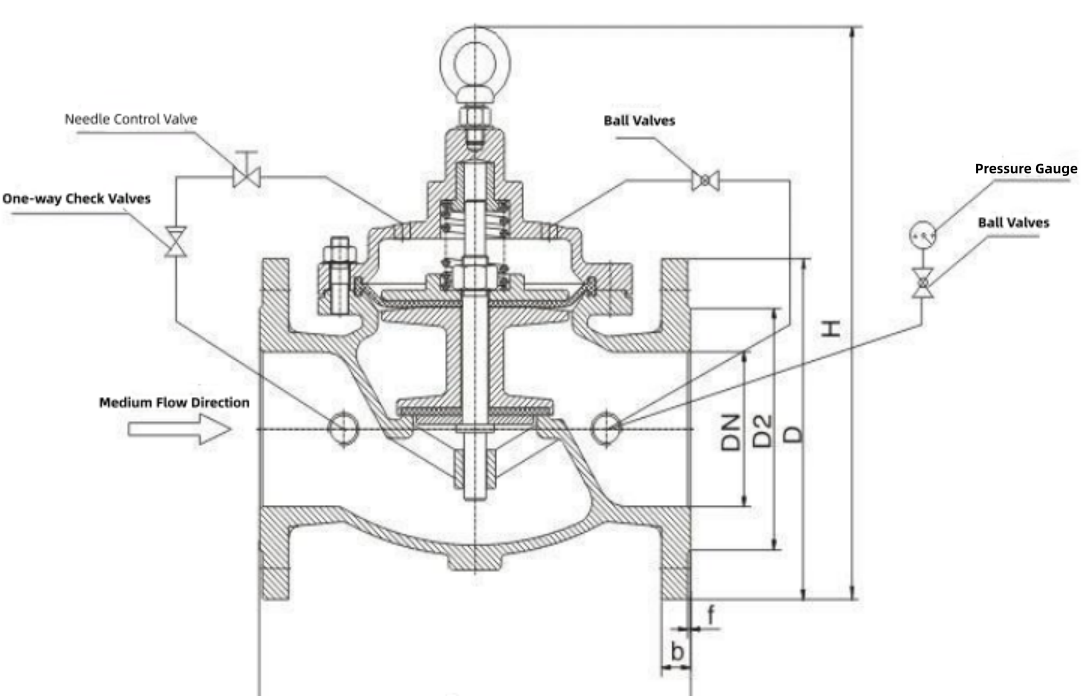

A 20-inch gate valve typically features a robust construction, often made of materials such as cast iron, stainless steel, or carbon steel, depending on its application and the fluid it will handle. Its size allows for significant volume control, making it suitable for large pipelines and high-capacity systems. Key design features include

1. Bonnet The bonnet houses the valve stem and provides support to the valve body. It can be bolted or welded, depending on the design and application.

2. Gate The gate can be either a wedge or a parallel disk. Wedge gates are common for larger valves due to their ability to provide a good seal when closed.

3. Stem The valve stem connects the gate to the actuator. It can be operated manually with a handwheel or automatically through an actuator.

4. Sealing Mechanism Proper sealing is vital for preventing leaks. Many 20-inch gate valves come equipped with resilient seat designs that ensure tight sealing under various pressure conditions.

5. Actuation Besides manual operation, gate valves can be fitted with pneumatic or electric actuators for remote control, enhancing operational efficiency.

Applications

The 20-inch gate valve is widely used in numerous applications

gate valve 20 inch

1. Water and Wastewater Treatment These valves control flow rates and isolate sections of pipelines for maintenance or repair.

2. Oil and Gas Industry They play a crucial role in managing flow in transmission pipelines, refineries, and processing plants where large volumes of liquid are transported.

3. Manufacturing Processes In various production facilities, gate valves regulate the supply of fluids, ensuring smooth operation.

4. Fire Protection Systems These valves are also used in fire suppression systems to control water flow to fire hoses and sprinkler systems.

Maintenance Considerations

Like all mechanical devices, regular maintenance is essential for the longevity and reliable operation of a 20-inch gate valve. Maintenance tasks include

1. Inspection Periodic visual inspections for leaks, corrosion, or mechanical wear can help catch issues early.

2. Lubrication The stem and threads should be regularly lubricated to ensure smooth operation and to minimize wear.

3. Exercise the Valve Regular opening and closing of the valve helps prevent the gate from becoming stuck.

4. Seal Replacement Over time, seals can wear out, so timely replacement is necessary to prevent leaks.

Conclusion

The 20-inch gate valve offers a reliable and efficient solution for controlling fluid flow in large diameter pipelines across various industries. Its operational reliability, coupled with the ability to handle substantial volumes, makes it a preferred choice for engineers and operators alike. Understanding the design, functionality, applications, and maintenance of these valves is crucial for their effective implementation in industrial settings. By ensuring proper maintenance, one can extend the lifespan of a gate valve while optimizing performance in operational tasks.

-

Why Metric Trapezoidal Thread is Ideal for Precision Motion ControlNewsAug.05,2025

-

The Unique Properties of a Block of Granite for Industrial UseNewsAug.05,2025

-

The Role of Flanged Y Strainers in Preventing Pipeline ClogsNewsAug.05,2025

-

The Importance of Regular Calibration for Master Ring GagesNewsAug.05,2025

-

How a Cast Iron Surface Table Enhances Accuracy in ManufacturingNewsAug.05,2025

-

Comparing Different Check Valve Types for Optimal Flow ControlNewsAug.05,2025

Related PRODUCTS