Dec . 15, 2024 23:07 Back to list

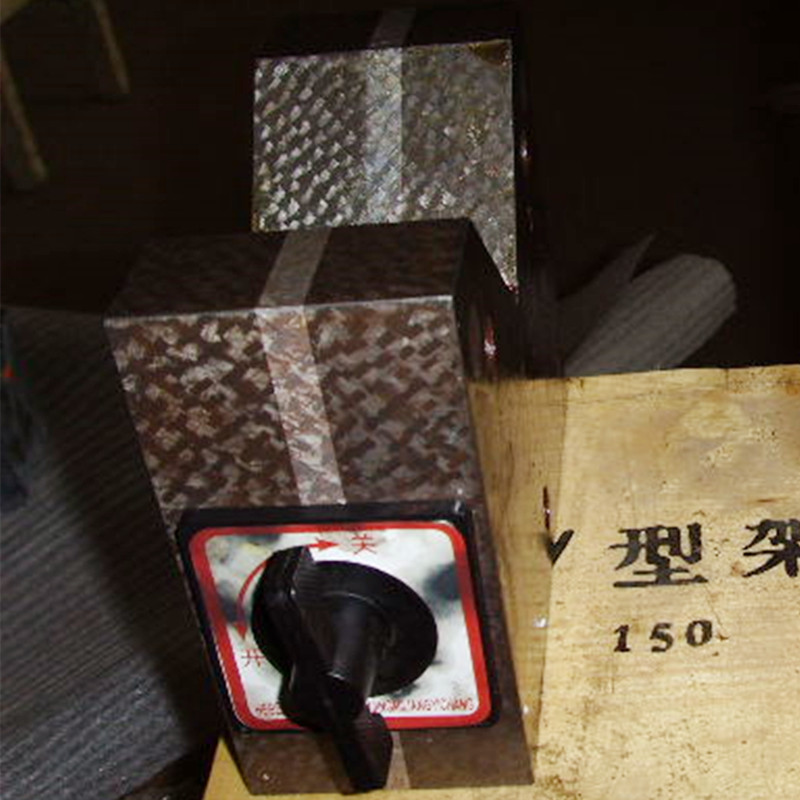

150 gate valve

Understanding the 150% Gate Valve What You Need to Know

Gate valves are essential components in various industrial applications, designed to start or stop fluid flow. Among the different types of gate valves available, the 150% gate valve has gained notoriety for its reliability and performance under pressure. This article will delve into the specifics of the 150% gate valve, its applications, advantages, and maintenance practices to ensure optimal performance.

What is a 150% Gate Valve?

A 150% gate valve typically refers to a valve designed to operate effectively at pressures up to 150% of its rated pressure. This feature makes it a robust option for situations where surges or spikes in pressure may occur. The term itself indicates that the gate valve can handle pressures significantly above standard operating conditions, providing a safety margin that can be crucial in many applications.

Key Features and Design

Gate valves operate using a wedge-shaped gate that slides between two seats. When the valve is fully opened, the gate is lifted entirely out of the fluid path, allowing for minimal resistance and ensuring an unobstructed flow. Key features of the 150% gate valve include

1. Material Construction These valves are usually made from durable materials such as stainless steel, bronze, or ductile iron, selected for their ability to withstand high pressures and extreme temperatures.

2. Design Variations They come in various designs, including rising stem and non-rising stem configurations, allowing for flexibility based on installation requirements and space constraints.

3. Pressure Ratings The hallmark of a 150% gate valve is its enhanced pressure rating, making it suitable for high-pressure applications found in oil and gas industries, chemical manufacturing, and water supply systems.

Applications

The 150% gate valve is widely used across multiple sectors due to its high pressure tolerance. Common applications include

- Oil and Gas Industry In crude oil extraction and refining processes, where high-pressure conditions are common, the 150% gate valve ensures safe and efficient operation.

- Chemical Processing These valves are integral in managing the flow of corrosive substances while maintaining system integrity under variable pressure conditions.

- Water Supply Systems Municipal water systems rely on sturdy gate valves to control the flow and pressure, especially during maintenance or emergency situations.

150 gate valve

- Power Generation In power plants, 150% gate valves help regulate steam and water flow, crucial for maintaining operational efficiency and safety standards.

Advantages of Using a 150% Gate Valve

1. Durability The materials and construction of these valves are designed to endure high pressures, making them less susceptible to failure under extreme conditions.

2. Versatility These valves can be utilized in a variety of applications, serving diverse industries and accommodating a wide range of fluid types.

3. Cost-Effectiveness Although the initial cost may be higher, their functionality and reliability can lead to lower maintenance costs and reduced downtime in operations.

4. Safety Assurance With the capability to handle pressures beyond standard ratings, the 150% gate valve provides an additional layer of safety, protecting systems from potential over-pressure scenarios.

Maintenance Considerations

To ensure the longevity and optimal performance of a 150% gate valve, regular maintenance is crucial

- Visual Inspections Regular checks for signs of wear, corrosion, or leaks can help identify issues before they become significant problems.

- Operational Checks Periodic testing of the valve's functionality under operating conditions will ensure that it performs as expected.

- Lubrication Keeping the stem and operating mechanisms lubricated can enhance performance and ease actuation.

- Record Keeping Maintaining a log of inspections, maintenance activities, and operational performance can assist in early detection of recurring issues and facilitate timely interventions.

Conclusion

The 150% gate valve is a critical component in many industries, providing a vital combination of robust design, reliability, and operational safety. By understanding its features, applications, and maintenance needs, operators can maximize efficiency and ensure safety in fluid handling systems. Investing in quality gate valves and committing to regular maintenance can make a significant difference in operational continuity and system integrity.

-

Y Type Strainer Maintains System Efficiency Long TermNewsJul.15,2025

-

Valve Selection Guide for Industrial ApplicationsNewsJul.15,2025

-

Steel Fab Table Provides Durable Work Surface for WeldingNewsJul.15,2025

-

Pad Iron Provides Stable Support for Heavy MachineryNewsJul.15,2025

-

One Inch Check Valve Fits Standard Plumbing SystemsNewsJul.15,2025

-

Measuring Micrometer Ensures Precise Dimensional AccuracyNewsJul.15,2025

Related PRODUCTS