Aug . 17, 2024 10:31 Back to list

150 mm Butterfly Valve Specifications and Applications for Efficient Flow Control

Understanding the 150 mm Butterfly Valve A Key Component in Industrial Applications

Butterfly valves, known for their simple design and ease of operation, have emerged as a crucial component in various industries, particularly for regulating and isolating flow in pipes. When discussing the 150 mm butterfly valve, it is important to delve into its design, working mechanism, applications, and benefits, which highlight why it is favored in many industrial setups.

Design and Mechanism

The 150 mm butterfly valve consists of a circular disc that rotates on an axis through the center of the disc. This disc is positioned perpendicular to the flow when closed and parallel when opened. The valve body is typically constructed from materials like ductile iron, stainless steel, or plastic, designed to withstand different pressures and temperatures depending on the application. The compact design of the valve allows it to be installed in tight spaces, making it ideal for various applications.

Operating a butterfly valve is straightforward; turning the handle or actuator rotates the disc, either blocking or allowing fluid flow through the pipe. This quick and straightforward operation is one of the main reasons for its popularity, as it provides efficient flow control.

Understanding the 150 mm Butterfly Valve A Key Component in Industrial Applications

The versatility of the 150 mm butterfly valve makes it suitable for a wide range of applications. It is commonly used in water treatment facilities, oil and gas pipelines, HVAC systems, and food processing industries. For instance, in wastewater treatment plants, butterfly valves are used to regulate the flow of water and waste materials efficiently. Similarly, in the HVAC sector, they manage air and water flow, enhancing system efficiency and performance.

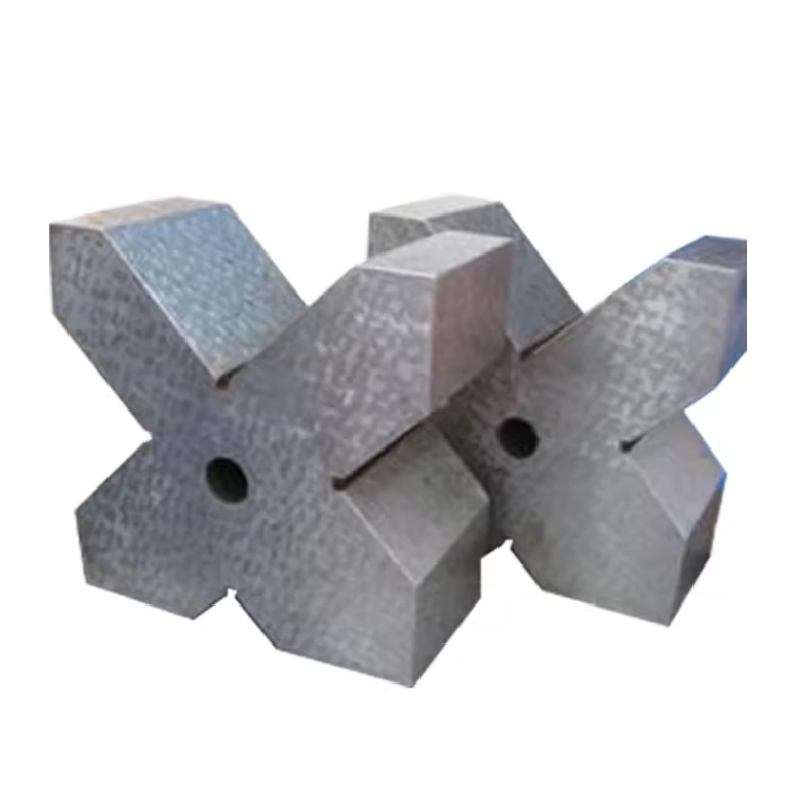

butterfly valve 150 mm

In the food and beverage industry, hygienic butterfly valves are utilized, ensuring compliance with safety standards while allowing for the easy cleaning of the system. Their capacity to seal tightly also makes them ideal for applications requiring high levels of hygiene and low contamination risk.

Benefits

One of the major advantages of using butterfly valves, especially those with a size of 150 mm, lies in their lightweight and compact design. Traditional valves can be significantly bulkier, making installation and maintenance more cumbersome. In contrast, the butterfly valve’s streamlined design reduces weight and footprint, translating into lower installation costs.

Moreover, butterfly valves are generally more cost-effective due to their simpler construction and the lower material cost compared to other valve types like gate or globe valves. Their operation requires less torque to open and close, which means that smaller actuators can be used, further reducing costs and improving responsiveness.

Additionally, butterfly valves exhibit excellent throttling capabilities. While they are often considered isolation valves, they can efficiently control flow rates in various applications, offering users versatile control over their systems.

Conclusion

In summary, the 150 mm butterfly valve stands out in industrial applications for its efficient and reliable performance. Its simple design, ease of operation, and versatility make it a preferred choice in industries that require reliable flow control. Understanding its components and functionalities allows operators to harness its full potential, ensuring optimal performance and efficiency in their processes. As industries continue to evolve, the butterfly valve will undoubtedly remain a key player in fluid management systems, embodying the principles of simplicity and efficiency.

-

Water Valve Gate Design Prevents Leakage and CorrosionNewsJul.11,2025

-

Steel Fab Table Features Reinforced Construction for LongevityNewsJul.11,2025

-

Specialized Valve Designs for High Pressure SystemsNewsJul.11,2025

-

Machinist Gauge Pins Feature Ground and Lapped FinishesNewsJul.11,2025

-

Hose Check Valve Prevents Backflow in Irrigation LinesNewsJul.11,2025

-

Durable Micrometer Tools Withstand Heavy Workshop UseNewsJul.11,2025

Related PRODUCTS