Electric soft seal gate valve

Electric soft seal gate valve

【Working temperature】0~80℃

【Suitable medium】Water, steam, oil, etc

【Application】Electricity, construction, environmental protection, water treatment, water supply and drainage, etc

Product Advantages

- 1.QT450-10 ductile iron body, 3 levels spheroidization rate, the tensile strength is 450MPa, the extension rate is over 10%. It is not easy to crack and freeze crack.

2. Epoxy coating for both valve inside and outside. Over 250μm coating thickness. Effectively prevent valve body corrosion and rust. It can be used in sewage system.

3. 50% rubber content EPDM coated DI wedge. The rubber is firmly coated with wedge, which is not easy to fall off.

4. 2Cr13 valve stem. Three O-ring sealing design. Reduce frictional resistance when switching, avoid medium exposure.

5. Brass stem nut and positioning device, switch smoother and avoids jamming during operation.

6. IP65 protection level electric actuator .

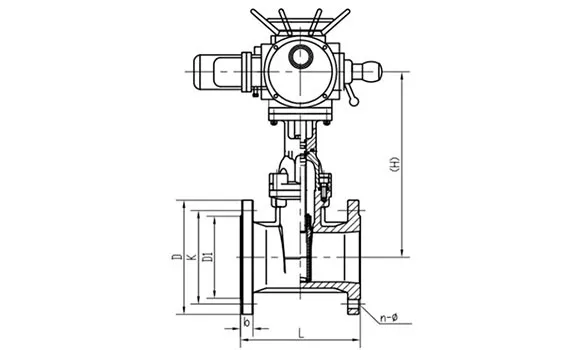

Parameter information

|

Name |

Design and manufacture |

Face to face Length |

Pressure Test |

Top Flange |

|

Reference standard |

CJ/T 216 |

GB/T 12221 |

CJ/T 216 |

GB/T 17241.6 |

|

Name |

1-Body |

2-Wedge |

3-Stem |

4-Electric actuator |

|

Material |

DI |

DI+EPDM |

2Cr13 |

component |

|

Nominal size |

|

PN16 |

150LB |

|||

|

DN |

NPS(inches) |

L |

K |

n-φ |

K |

n-φ |

|

50 |

2'' |

178 |

125 |

4-19 |

120.7 |

4-19 |

|

65 |

2 1/2'' |

190 |

145 |

4-19 |

139.7 |

4-19 |

|

80 |

3'' |

203 |

160 |

8-19 |

152.4 |

4-19 |

|

100 |

4'' |

229 |

180 |

8-19 |

190.5 |

8-19 |

|

125 |

5'' |

254 |

210 |

8-19 |

215.9 |

8-22 |

|

150 |

6'' |

267 |

240 |

8-23 |

241.3 |

8-22 |

|

200 |

8'' |

292 |

295 |

12-23 |

298.5 |

8-22 |

|

250 |

10'' |

330 |

355 |

12-26 |

362 |

12-25 |

|

300 |

12'' |

356 |

410 |

12-26 |

431.8 |

12-25 |

|

350 |

14'' |

381 |

470 |

16-26 |

476.3 |

12-29 |

|

400 |

16'' |

406 |

525 |

16-30 |

539.8 |

16-29 |

|

450 |

18'' |

432 |

585 |

20-30 |

577.9 |

16-32 |

|

500 |

20'' |

457 |

650 |

20-34 |

635 |

20-32 |

|

600 |

24'' |

508 |

770 |

20-37 |

749.3 |

20-35 |

|

700 |

28'' |

610 |

840 |

24-37 |

|

|

|

800 |

32'' |

660 |

950 |

24-40 |

||

|

900 |

36'' |

711 |

1050 |

28-40 |

||

|

1000 |

40'' |

811 |

1170 |

28-43 |

||

|

1200 |

48'' |

1015 |

1390 |

32-49 |

||

Related PRODUCTS

RELATED NEWS

Why Metric Trapezoidal Thread is Ideal for Precision Motion Control

In precision motion control systems, the choice of thread design directly impacts performance, and metric trapezoidal thread has emerged as a superior solution for its unique combination of accuracy and durability.

The Unique Properties of a Block of Granite for Industrial Use

In industrial manufacturing and precision measurement, the reliability of materials directly impacts operational accuracy, and a block of granite has emerged as an indispensable resource.

The Role of Flanged Y Strainers in Preventing Pipeline Clogs

In industrial pipeline systems, maintaining unobstructed flow is critical to operational efficiency, and flanged y strainer has emerged as a key component in achieving this goal.