3D Welding Table

Product Parameter

Place of Origin:Hebei

Warranty:1 year

Customized support: OEM, ODM

Brand Name :Storan

Model Number:2005

Product name:3D flexible welding platform material

Material: cast iron/Steel

Application :Industry

Pore size tolerance:±0.05mm

surface treatment t:Surface nitriding

Flatness:0.02mm/1000MM

Roughness:Ra1.6-Ra3.2

Process: CNC Machining

Type :Moulding Press

Certificate :ISO9001:2008

Packaging Details :plywood box 3D welding table with accessories OEM HT300 Black Oxide Finish 3D flexible Welding Table

Selling Units :Single item

Single package size:100X100X20 cm

Single gross weight:5000 kg

Lead time

|

Quantity (pieces) |

1 - 100 |

> 100 |

|

Lead time (days) |

5 |

To be negotiated |

3D welding table

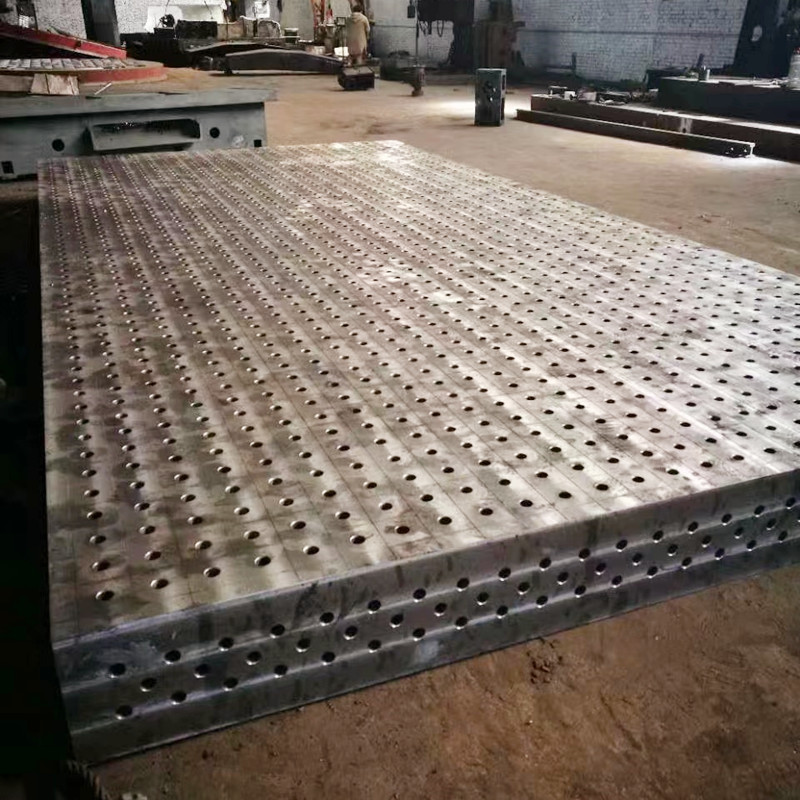

3D welding platform is an advanced welding platform, the platform

and four sides are distributed with holes of 28, used to coordinate with

the 3D flexible fixture, to achieve rapid positioning and clamping of the workpiece

that needs to be welded. The advantages of a 3D welding platform are high efficiency,

high precision, and low cost. A set of 3D welding tooling systems can basically

satisfy all customer welding parts.

Product Parameter

|

3d welding table specification sheet |

|||||

|

D28 series |

D16 series |

||||

|

Numbering |

specification |

weight |

Numbering |

specification |

weight |

|

JM-D28-1010 |

1000*1000*200 |

380KG |

JM-D16-1005 |

1000*500*100 |

70KG |

|

JM-D28-1212 |

1200*1200*200 |

430KG |

JM-D16-1010 |

1000*1000*100 |

120KG |

|

JM-D28-1015 |

1000*1500*200 |

450KG |

JM-D16-1208 |

1200*800*100 |

120KG |

|

JM-D28-1020 |

1000*2000*200 |

600KG |

JM-D16-1212 |

1200*1200*100 |

170KG |

|

JM-D28-1224 |

1200*2400*200 |

850KG |

JM-D16-1015 |

1000*1500*100 |

180KG |

|

JM-D28-1520 |

1500*2000*200 |

880KG |

JM-D16-1515 |

1500*1500*100 |

270KG |

|

JM-D28-1530 |

1500*3000*200 |

1300KG |

JM-D16-1020 |

1000*2000*100 |

250KG |

|

JM-D28-2030 |

2000*3000*200 |

1800KG |

JM-D16-1224 |

1200*2400*100 |

350KG |

|

JM-D28-2040 |

2000*4000*200 |

2700KG |

|

|

|

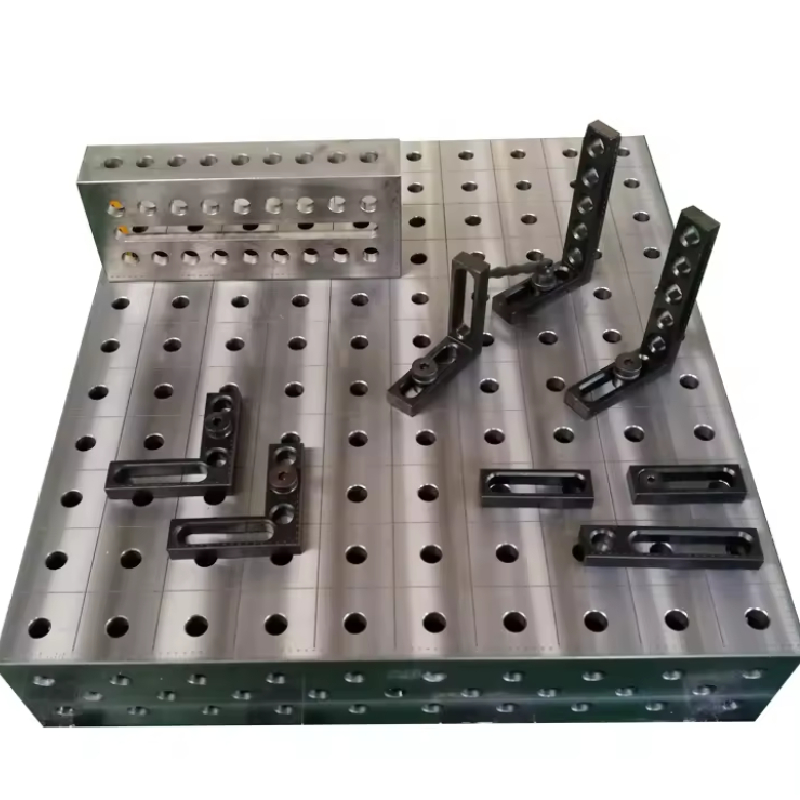

Product Overview

Components can be equipped after your select the following:

1, Tools for supporting: U-shaped cube case, L-shaped cube case, Angle supporting, and Angle gauge

2, spare parts for Locating:

3, Tools for clamping and fixing

4, spare parts for locking working piece

5, Auxiliary Tools

3D welding table 1.2x2.4 1x2 1.5x3 2x4m have in stock cast iron table and fixture table

- - Dimensions:1000X1000mm-2000X4000mm

- - Five working surfaces the locating piece can be installed on. Also can be extended via any of its five working surfaces.

- - Its material is divided into: Steel Welding Tables (Q345) and Casting Welding Tables (HT300).

- - Its hole diameter is divided into: D28 series and D16 series.

- - Diagonal Grid: D28 is 100*100mm; D16 is 50*50mm.

Features

Supporting: legs, steel frame, and hydraulic lift box, according to the requirement.

The 3D welding platform is a universal fixture designed specifically for the manufacturing of welded products; Used for welding convenience, flexibility, and many different from traditional welding methods.

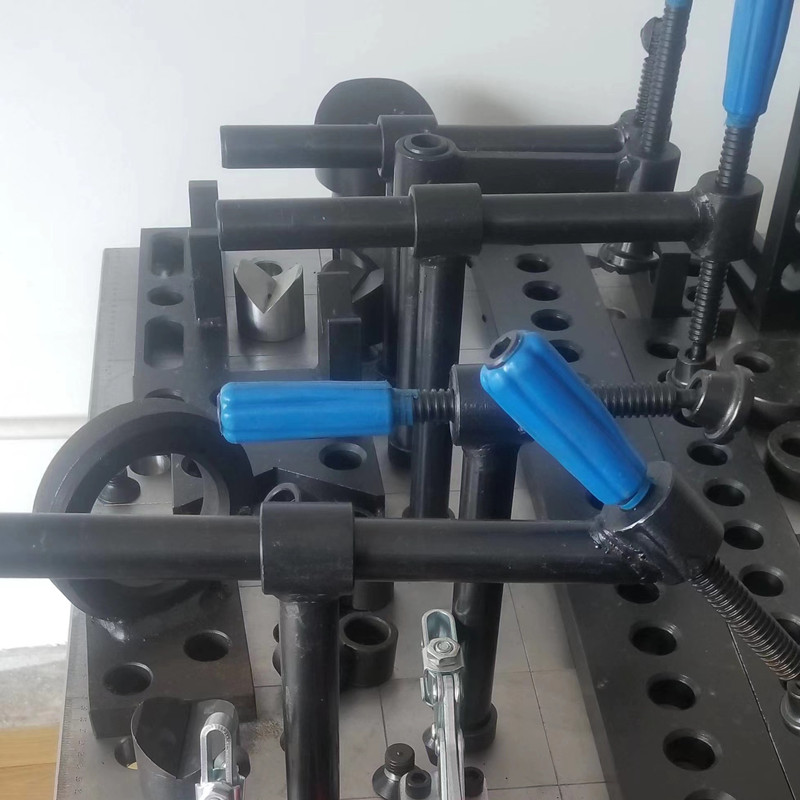

Three-dimensional hole system combination flexible welding process equipment.

Three dimensions: represent three directions. Generally, fixtures are longitudinal and transverse without vertical directions. The platform has two directions, and the four edges can be used for vertical installation, achieving a three-dimensional combination.

Hole system: The main feature of this fixture is that from the platform to the accessories, there are standard holes without traditional threads or T-slots. Coupled with quick locking pins, assembly can be made faster and more convenient, and positioning can be achieved.

Combination: Because all attachments are pre-made, they can be combined and adjusted according to the needs of the product.

Flexibility: With the above-mentioned functions, the entire set of equipment can change according to the changes of the product. A set of fixtures can meet the needs of several products or dozens of products, greatly accelerating the process of product research and development and trial production, saving a lot of manpower, material resources, and financial resources (environmentally friendly and low-carbon products).

Welding: This product is a universal fixture designed specifically for the manufacturing of welded products; Used for welding convenience, flexibility, and many different from traditional welding methods.

The basic requirements for anti-rust primer on a 3D welding platform are: good adhesion to the surface of the casting, good anti rust performance, good adhesion to the upper layer of paint, and easy construction and storage.

Top Features to Look for in a 3D Welding Table

When selecting a 3D welding table, it's essential to consider various features that significantly enhance productivity and precision in your welding projects. A high-quality 3D welding table can make all the difference in achieving optimal results. Here are the top features to look for:

1. Robust Construction: A sturdy 3D welding table should be made of high-grade materials capable of withstanding heavy loads and the rigors of welding processes. Look for tables constructed from durable steel or cast iron, ensuring longevity and stability.

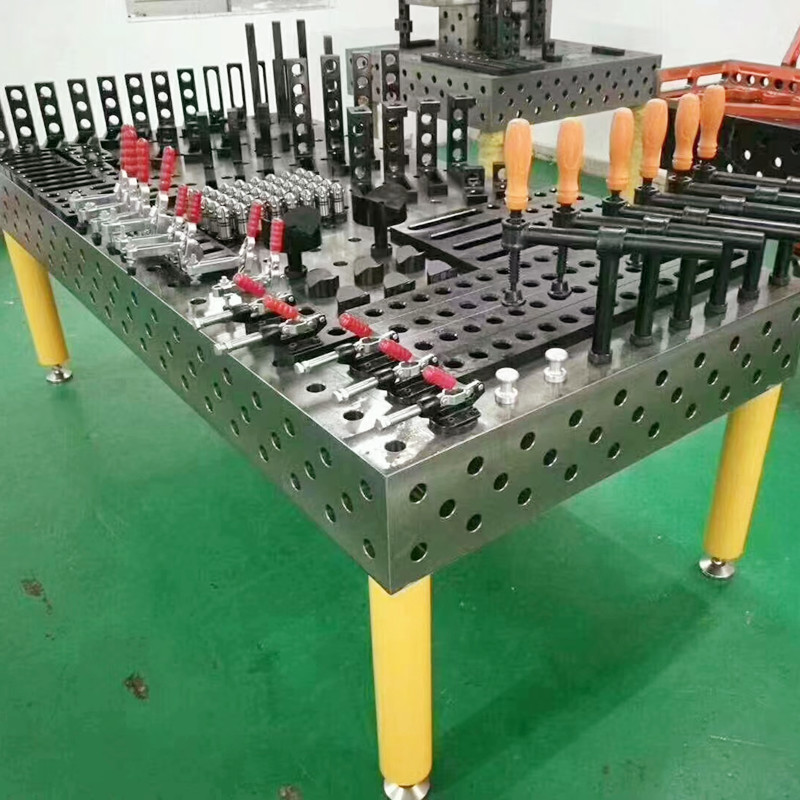

2. Modularity: The ability to customize and adjust your setup is crucial. A modular 3D welding table allows for the integration of various add-ons and accessories, enabling you to tailor your workspace to suit specific projects, whether it's small-scale intricate designs or large assemblies.

3. Precision Machining: To achieve utmost accuracy, the surfaces and slots in the 3D welding table should be precisely machined. Look for tables that offer a grid pattern with accurately spaced holes and slots, which facilitate the secure clamping and positioning of workpieces.

4. Versatile Clamping Options: Effective clamping solutions are vital for ensuring stability during the welding process. A quality 3D welding table should provide a variety of mounting points and clamps, allowing for flexible configurations and secure hold on different shapes and sizes of materials.

5. Compatibility with Fixtures: Ensure that the 3D welding table you choose is compatible with various fixturing systems. This compatibility will enhance your ability to create custom setups quickly and efficiently, saving you time and increasing productivity.

6. Surface Treatment: A surface that resists contamination and wear is vital in a welding environment. Look for tables with anti-spatter coatings or finishes that help maintain a clean work surface and prolong the table's lifespan.

Benefits of Using a 3D Welding Table for Precision Work

In the world of metal fabrication, achieving accuracy and precision is paramount for successful projects. One of the most effective tools available for welders is the precision 3D welding table. This essential equipment not only enhances productivity but also significantly improves the quality of the finished work.

A precision 3D welding table is designed with a robust framework that allows for customizable setups tailored to the specific requirements of each project. The surface is typically made of high-quality materials, ensuring durability and stability during welding operations. This stability can prevent warping or distortion of the metal parts being worked on, which is crucial for maintaining high precision standards.

Another significant benefit of using a precision 3D welding table is the advanced jigs and fixtures it can accommodate. Many of these tables come with T-slots or holes that enable welders to clamp down components securely. This feature is essential for multi-dimensional projects, where maintaining the correct configuration is vital. As a result, the risk of misalignment and errors is greatly reduced, allowing for clean and precise welds.

Moreover, the use of a precision 3D welding table can streamline workflow and reduce time spent on each project. By providing a designated workspace that is organized and efficient, welders can focus more on the creative and technical aspects of their work rather than on the setup. This increased efficiency leads to higher productivity levels and ultimately better profitability for businesses.

In conclusion, investing in a precision 3D welding table is a game changer for any professional welder looking to enhance their craft. With its ability to provide stability, customizability, and efficiency, it is an invaluable tool that supports high-quality and precise welding work. Whether you are a seasoned expert or a novice in the welding field, utilizing a precision 3D welding table will undoubtedly elevate your projects to the next level.

Core Functions and Industrial Application Value of 3D Welding Tables

STORAEN’s 3D welding tables redefine precision and efficiency in industrial welding fabrication, serving as versatile modular platforms designed to streamline workpiece positioning, fixture integration, and multi-axis welding operations. As a leading provider of welding fabrication tables, we deliver solutions that combine high rigidity, customizable configurations, and repeatable accuracy—essential for modern manufacturing environments demanding zero-defect welding results.

Precision Positioning at the Core

At the heart of our 3D welding table design is a five-sided grid of precision-machined holes (D28 or D16 series), enabling seamless attachment of clamps, angles, and fixtures across the top surface and all four side panels. This grid system (100x100mm or 50x50mm spacing) ensures positional accuracy within ±0.05mm, eliminating the guesswork in aligning complex components like automotive chassis frames, aerospace brackets, or heavy-duty machinery parts. The result? A repeatable welding setup that reduces trial-and-error adjustments by 60%, critical for mass production where consistency is non-negotiable.

Modular Flexibility for Diverse Fabrication Needs

Our welding fab tables thrive on adaptability:

Multi-Platform Integration: Standard sizes (1000x1000mm to 2000x4000mm) can be bolted together using quick-lock pins, creating extended work surfaces for oversized projects—ideal for shipbuilding or agricultural equipment assembly.

Tool-Free Fixture Changes: Compatible with a wide range of welding accessories (U-blocks, T-slots, magnetic clamps), the table allows rapid reconfiguration between different jobs, cutting fixture setup time by 50% compared to traditional fixed-position tables.

Heavy-Duty Load Capacity: Constructed from HT300 cast iron or Q345 steel with ribbed understructure, these tables withstand static loads up to 2700kg, supporting even the largest industrial components without deflection—a must for excavator arm welding or crane structure fabrication.

Industrial Applications: Where Precision Meets Productivity

Automotive Manufacturing

Use as a welding fabrication table for assembling car body frames, ensuring spot welds align within ±0.1mm to meet OEM quality standards. The anti-spatter coating option protects the surface from welding debris, extending service life in high-volume production lines.

Aerospace & Defense

Critical for fabricating lightweight aluminum alloy structures (e.g., aircraft engine mounts), where the table’s thermal stability (minimal expansion under welding heat) and flatness (0.02mm/1000mm) prevent dimensional deviation that could compromise flight safety.

Heavy Machinery & Equipment

The go-to solution for welding bulldozer frames or industrial pump casings, thanks to its robust construction and modular design that accommodates odd-shaped workpieces through custom fixture installations.

Why STORAEN 3D Welding Tables Lead the Way

Beyond core functions, our tables feature:

Surface Finish Excellence: A ground surface (Ra1.6-Ra3.2) ensures smooth fixture movement and precise alignment, while optional nitriding treatment enhances wear resistance in abrasive welding environments.

Global Standard Compliance: Certified to ISO 9001 and JB/T7974-99, our 3D welding tables meet the rigorous demands of international fabrication standards, providing peace of mind in cross-border projects.

Elevate Your Welding Process with STORAEN

Whether you need a compact welding fab table for prototyping or a large-scale 3D welding table for mass production, STORAEN’s solutions deliver the precision, durability, and flexibility required to stay ahead in modern fabrication. By minimizing setup time, maximizing fixture compatibility, and ensuring repeatable accuracy, our tables transform welding from a manual, error-prone process into a streamlined, automated workflow—empowering your team to build better, faster, and with unmatched confidence.

Accessory Systems and Custom Solutions for 3D Welding Tables

STORAEN’s 3D welding tables are complemented by a comprehensive accessory system and tailored custom solutions, designed to maximize versatility, precision, and adaptability for every welding fabrication need. Whether you require standard components for quick setup or bespoke modifications for unique projects, our offerings transform your welding fabrication table into a highly specialized workstation—engineered to meet the exacting demands of modern manufacturing.

Modular Accessory Ecosystem for Seamless Integration

Our plug-and-play accessories enhance the functionality of your welding fab table, enabling rapid configuration changes and optimized workflow:

Support & Leveling Tools: Adjustable steel legs with anti-vibration pads ensure stable setup on uneven shop floors, while hydraulic lifting systems (100–500mm height range) enable ergonomic positioning for overhead or hard-to-reach welds.

Fixturing & Clamping Solutions: A range of magnetic clamps, toggle clamps, and U-blocks (compatible with D28/D16 hole systems) secure workpieces of all shapes and sizes, with quick-release mechanisms reducing fixture installation time by 40%. Angled brackets (0–90° adjustable) and precision squares aid in multi-axis alignment, critical for complex assemblies like robotic arms or aerospace trusses.

Safety & Protection Add-ons: Anti-spatter coatings (applied to table surfaces) and removable splash guards minimize debris accumulation, while heat-resistant mats protect the grid system from prolonged exposure to welding arcs—extending the table’s service life in high-intensity fabrication environments.

Custom Solutions: Engineered to Your Vision

Tailored Dimensions & Configurations

Beyond standard sizes (1000x1000mm to 2000x4000mm), we design 3D welding tables in custom lengths, widths, and heights—including oversized platforms (up to 5000x3000mm) for industrial-scale projects. Non-rectangular shapes (circular, L-shaped) and recessed mounting areas accommodate specialized machinery or automated welding robots, ensuring seamless integration into your production line.

Precision-Machined Features

Hole System Customization: Adjust hole spacing (e.g., 75x75mm for hybrid grids) or specify metric/imperial thread types (M12, ½”-13 UNC) to match existing fixtures, eliminating the need for adapter plates.

Surface Treatments: Choose from ground finishes (Ra1.6 for standard use) or super-finished surfaces (Ra0.8 for metrology-grade alignment), with optional nitriding (HV900+) to enhance hardness and resist abrasive wear in heavy-duty applications.

Industry-Specific Modifications

Automotive: Integrated T-slots for conveyor belt alignment, ideal for high-speed car part welding cells.

Aerospace: Non-magnetic stainless steel inserts to prevent interference with sensitive NDT (non-destructive testing) equipment during aluminum alloy welding.

Marine: Epoxy-coated undersides for corrosion resistance in saltwater environments, paired with reinforced corner brackets for offshore rig component fabrication.

Rapid Turnaround & Global Support

Stock Accessories: Most clamps, legs, and leveling tools ship within 24 hours, ensuring minimal downtime for production line adjustments.

Custom Lead Times: Standard custom tables (non-complex designs) are delivered in 15–20 days, with dedicated engineering support to refine drawings and material selections (e.g., stainless steel for food-grade applications).

Certified Quality: All custom 3D welding tables undergo rigorous flatness testing (0.02mm/1000mm) and load-bearing validation, accompanied by ISO 9001-compliant calibration reports for traceable quality control.

Unlock the Full Potential of Your Welding Fab Table

With STORAEN’s accessory systems and custom solutions, your welding fabrication table becomes more than a workbench—it’s a scalable platform for innovation. Whether you need off-the-shelf components for immediate productivity gains or a fully customized 3D welding table for a groundbreaking project, our team combines engineering expertise with manufacturing agility to deliver solutions that match your vision. Elevate your welding operations with accessories that adapt and customizations that transform—because in fabrication, precision is everything, and one size never fits all.

Product Content

The commonly used anti-rust primer is grease paint. Natural resin paint. Asphalt paint. Phosphating paint, etc. Their performance and application range vary. The welded flat plate has been cleaned. After passing the inspection. Usually, anti rust paint is applied on nonmachined surfaces or all surfaces. When applying, it should be carefully understood that in the selection and production of welding flat plates, the manual painting process is generally simple. Economically convenient and suitable for single piece production of castings.

- T he working environment of the welding platform. The working environment suitable for various anti-rust paints varies. Therefore, when choosing, one should understand the working environment of the welded flat plate.

- Primer and topcoat do not need to be matched. Welding flat plates, in addition to primer. And it needs to be painted on top. Most topcoats are applied after mechanical processing, so the adhesion between the primer and topcoat should be considered. Generally, primers and topcoats prepared with similar paint materials are matched. Primers and topcoats prepared with different types of paints may not be compatible due to their strong adhesion. They cannot bond well with each other. Therefore, it is necessary to understand the performance of the paint.

- The construction method of anti-rust primer. Each anti-rust primer has its own good construction and coating method. To confirm whether the factory or workshop has such conditions, the welded flat plate is manufactured according to the JB/T7974-99 standard. The product is made into ribbed plate and box type. The working face has a rectangular shape, made of HT200 material. The working face adopts scraping and grinding technology, and a V-shape can be machined on the working face. T-shaped. U-shaped grooves and circular holes. Long holes, etc. Welding flat plate is a flat reference tool used for workpiece welding, and the flat plate should be adjusted to the horizontal according to the installation requirements. The load is evenly distributed on each support point. When using at an ambient temperature of 20 ± 5 ℃, vibration should be avoided.

Product Detail Drawing

Related PRODUCTS

RELATED NEWS

Thread Plug Gauge Our Promise of Measurement Excellence

At Storaen (Cangzhou) International Trading Co., we manufacture precision thread plug gaug

Gauge Pin Class Reflecting Quality Legacy

At Storaen (Cangzhou) International Trading Co., we manufacture precision pin gauge i

Check Valve Types for High Rise Buildings

At Storaen (Cangzhou) International Trading Co., we specialize in engineering premium chec