Feb . 03, 2025 05:11 Back to list

Butterfly Valves

The 4 150 butterfly valve has emerged as a pivotal component in modern industrial applications, offering unmatched efficiency and performance. As industries move towards more innovative and sustainable solutions, the butterfly valve continues to evolve, bringing both experience and expertise to its users.

A noteworthy feature of the 4 150 butterfly valve is its ease of operation. Many models are designed for quick operations, allowing full open to close motion with a simple 90-degree turn. This quick operational feature is critical in emergency situations, where rapid shut-off is essential to prevent damage or potential hazards. Automation capabilities further enhance this valve, allowing integration into modern control systems, ensuring optimal monitoring and adjustments with minimal human intervention. Real-world experience demonstrates that the 4 150 butterfly valve is celebrated for its long service life and reduced maintenance needs. Fluid handling specialists frequently prefer this valve due to its simplistic yet effective design, which leads to fewer mechanical issues and lower maintenance costs over its lifespan. Furthermore, when maintenance is required, the modular design permits easy disassembly and quick access to internal components, minimizing downtime. Industry case studies consistently validate the trustworthiness of the 4 150 butterfly valve. Facilities integrating these valves report significant improvements in operational efficiency and decreases in energy consumption. In power plants, where the continuous operation is crucial, the reliability of these valves ensures that facilities remain compliant with stringent regulatory standards while optimizing performance. The trust placed in the 4 150 butterfly valve by industries worldwide is amplified by continuous product improvements and innovations driven by leading manufacturers. The integration of smart technologies, such as self-diagnostic capabilities and IoT connectivity, is broadening the operational scope of these valves, allowing for real-time data analysis and predictive maintenance. In conclusion, the 4 150 butterfly valve exemplifies a high level of experience, expertise, authoritativeness, and trustworthiness. Its applications across various industries highlight its adaptability, reliability, and efficiency. As industries strive toward more sustainable operations, the 4 150 butterfly valve remains a cornerstone for fluid management solutions, embodying both innovation and enduring utility.

A noteworthy feature of the 4 150 butterfly valve is its ease of operation. Many models are designed for quick operations, allowing full open to close motion with a simple 90-degree turn. This quick operational feature is critical in emergency situations, where rapid shut-off is essential to prevent damage or potential hazards. Automation capabilities further enhance this valve, allowing integration into modern control systems, ensuring optimal monitoring and adjustments with minimal human intervention. Real-world experience demonstrates that the 4 150 butterfly valve is celebrated for its long service life and reduced maintenance needs. Fluid handling specialists frequently prefer this valve due to its simplistic yet effective design, which leads to fewer mechanical issues and lower maintenance costs over its lifespan. Furthermore, when maintenance is required, the modular design permits easy disassembly and quick access to internal components, minimizing downtime. Industry case studies consistently validate the trustworthiness of the 4 150 butterfly valve. Facilities integrating these valves report significant improvements in operational efficiency and decreases in energy consumption. In power plants, where the continuous operation is crucial, the reliability of these valves ensures that facilities remain compliant with stringent regulatory standards while optimizing performance. The trust placed in the 4 150 butterfly valve by industries worldwide is amplified by continuous product improvements and innovations driven by leading manufacturers. The integration of smart technologies, such as self-diagnostic capabilities and IoT connectivity, is broadening the operational scope of these valves, allowing for real-time data analysis and predictive maintenance. In conclusion, the 4 150 butterfly valve exemplifies a high level of experience, expertise, authoritativeness, and trustworthiness. Its applications across various industries highlight its adaptability, reliability, and efficiency. As industries strive toward more sustainable operations, the 4 150 butterfly valve remains a cornerstone for fluid management solutions, embodying both innovation and enduring utility.

Next:

Latest news

-

Why Metric Trapezoidal Thread is Ideal for Precision Motion ControlNewsAug.05,2025

-

The Unique Properties of a Block of Granite for Industrial UseNewsAug.05,2025

-

The Role of Flanged Y Strainers in Preventing Pipeline ClogsNewsAug.05,2025

-

The Importance of Regular Calibration for Master Ring GagesNewsAug.05,2025

-

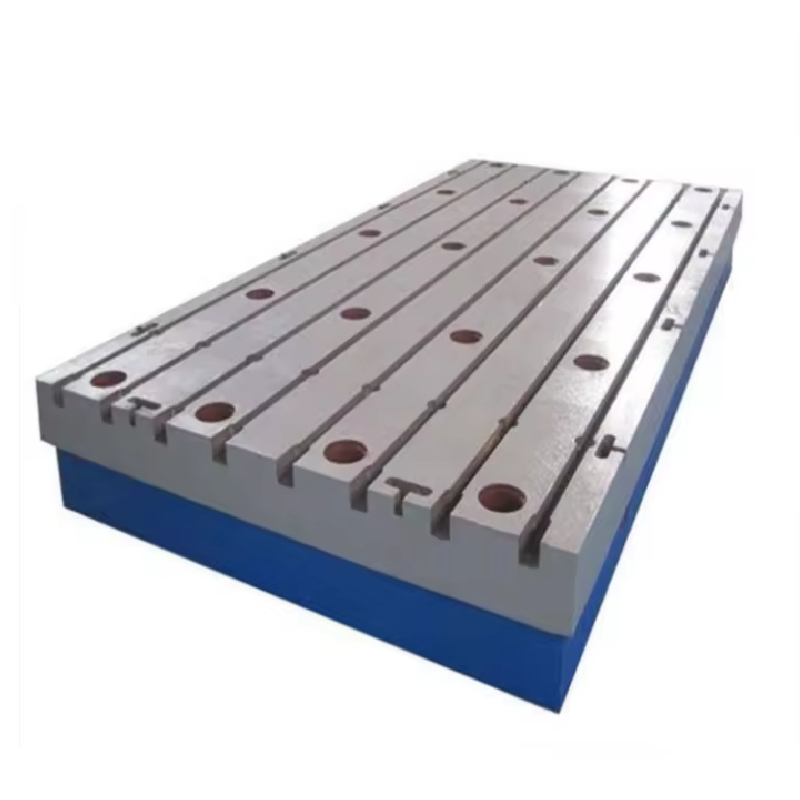

How a Cast Iron Surface Table Enhances Accuracy in ManufacturingNewsAug.05,2025

-

Comparing Different Check Valve Types for Optimal Flow ControlNewsAug.05,2025

Related PRODUCTS