Dec . 05, 2024 06:34 Back to list

Precision Granite Angle Plate for Accurate Measurement and Machining Applications

Understanding the Granite Angle Plate An Essential Tool in Precision Machining

Granite angle plates are integral components in the field of precision machining, serving as indispensable tools for a wide range of measuring and setup tasks. Known for their durability, stability, and accuracy, granite angle plates are often utilized in workshops and laboratories where precision is paramount. This article delves into the characteristics, applications, advantages, and maintenance of granite angle plates, highlighting why they are favored by professionals in various industries.

What is a Granite Angle Plate?

A granite angle plate is a tool typically made from solid granite, which is a type of igneous rock known for its hard and dense structure. These plates come in various sizes and are designed with right angles, allowing them to be used as reference points for measuring, aligning, and supporting workpieces. The flat surfaces of the angle plate provide a stable foundation, ensuring that measurements taken during machining processes are precise and repeatable.

Characteristics of Granite Angle Plates

1. Stability Granite is inherently stable and does not warp or deform over time, making granite angle plates exceptionally reliable over prolonged use.

2. Resistance to Wear The hard surface of granite is resistant to scratches and wear, which is crucial in maintaining the accuracy of the measuring surfaces.

3. Non-Magnetic Unlike metal plates, granite angle plates do not interfere with magnetic measuring tools, making them suitable for a wide range of applications.

4. Thermal Stability Granite has a low coefficient of thermal expansion, which means that it maintains its dimensions even under varying temperature conditions.

5. Excellent Surface Finish The polished surfaces of granite angle plates provide high precision and are easy to clean, which is particularly important in maintaining measurement accuracy.

Applications

Granite angle plates find usage in numerous applications across various industries. Some common uses include

- Inspection and Measurement Granite angle plates are often employed in quality control environments to inspect the dimensions of machined parts. The straight edges and stable surfaces allow for easy setup and measurement.

- Machining Setup In CNC machining and manual milling operations, granite angle plates serve as a base for securely holding components at required angles.

- Tapering and Alignment These plates aid in the alignment of workpieces for processes like grinding and drilling, ensuring that operations are performed at exact angles.

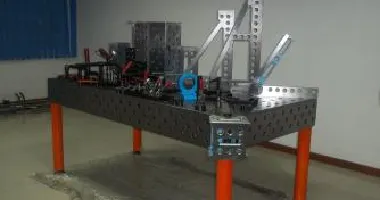

granite angle plate

- Layout Work Engineers and machinists use granite angle plates for laying out complex shapes and ensuring that all dimensions are accurate before proceeding with machining

.Advantages of Using Granite Angle Plates

The utilization of granite angle plates provides several benefits

- High Precision The durability and stability of granite enable high accuracy in measurements, which is critical in industries such as aerospace and automotive.

- Longevity Given their resistance to wear and environmental factors, granite angle plates have a long lifespan, making them a cost-effective investment for many businesses.

- Easy Maintenance Cleaning a granite surface is straightforward and requires minimal effort, ensuring that contaminants do not affect measurement accuracy.

- Versatility These plates can be used for various applications across different industries, from simple setups to complex measuring tasks.

Maintenance of Granite Angle Plates

To ensure the longevity and accuracy of granite angle plates, proper maintenance is essential. Here are some key maintenance tips

- Regular Cleaning Clean the surfaces with a soft cloth and non-abrasive cleaners. Avoid harsh chemicals that may damage the granite.

- Protection from Strikes Use precautions to protect the plates from physical impacts that could chip or damage the surface.

- Storage Store granite angle plates in a clean, dry place, ideally in a dedicated storage case to prevent dust accumulation and potential damage.

- Frequent Calibration Regularly check the accuracy of the angle plate using calibrated instruments to ensure it meets the required precision standards.

Conclusion

In summary, granite angle plates stand out as a vital tool in the precision machining industry. Their unique properties, such as stability, resistance to wear, and non-magnetic characteristics, make them exceptionally suitable for various applications. By understanding their uses and maintaining them properly, professionals can leverage the advantages offered by granite angle plates to achieve the highest standards of accuracy and efficiency in their work. Whether in manufacturing, inspection, or engineering, granite angle plates remain an essential asset in ensuring quality and precision.

-

Why Metric Trapezoidal Thread is Ideal for Precision Motion ControlNewsAug.05,2025

-

The Unique Properties of a Block of Granite for Industrial UseNewsAug.05,2025

-

The Role of Flanged Y Strainers in Preventing Pipeline ClogsNewsAug.05,2025

-

The Importance of Regular Calibration for Master Ring GagesNewsAug.05,2025

-

How a Cast Iron Surface Table Enhances Accuracy in ManufacturingNewsAug.05,2025

-

Comparing Different Check Valve Types for Optimal Flow ControlNewsAug.05,2025

Related PRODUCTS