جولائی . 14, 2025 09:58 فہرست پر واپس جائیں۔

Threaded Ring Gauge Measurement Uncertainty

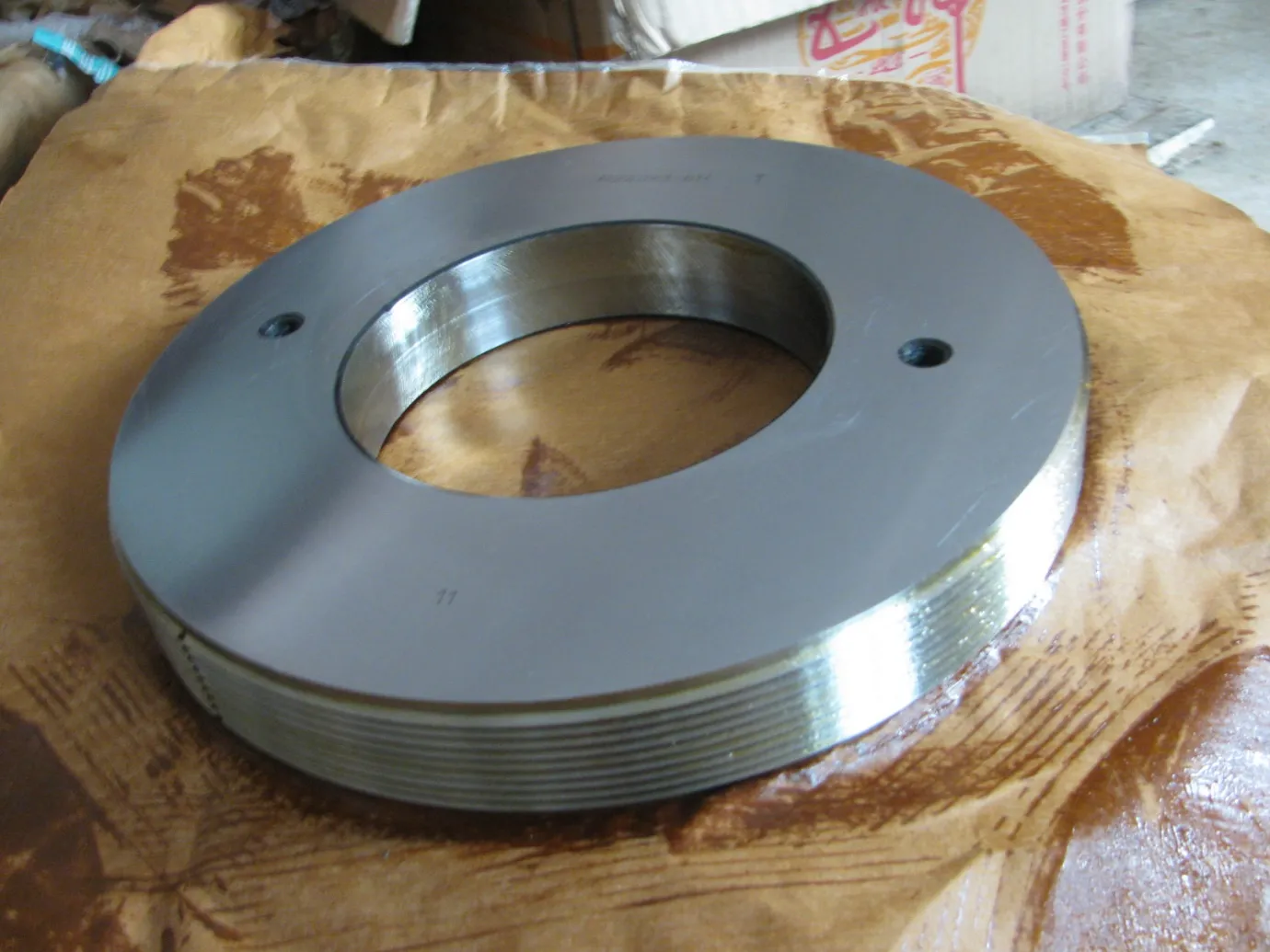

In the world of precision manufacturing and quality control, threaded ring gauges play a crucial role in ensuring the accuracy of external threads. These gauges, with their through end and stop end, are indispensable tools for verifying the correct size of threads. Storaen (Cangzhou) International Trading Co., a renowned manufacturing company based in Botou, China, has made a name for itself by specializing in a wide array of high-quality industrial products, including thread ring gauges. Their commitment to precision engineering and strict quality control, combined with the strategic advantage of being located in a major casting hub, allows them to produce reliable gauges that meet the highest industry standards. However, like any measurement tool, threaded ring gauges are subject to measurement uncertainty. Understanding this uncertainty is vital for obtaining accurate and reliable measurement results. Threaded ring gauges come in various specifications, such as coarse, fine, and pipe threads, and different accuracy grades, with some gauges not having a stop end based on specific pitch and accuracy requirements.

Understanding Measurement Uncertainty in Threaded Ring Gauges

- Definition and Significance: Measurement uncertainty for threaded ring gauges refers to the range of values within which the true measurement of an external thread's size likely lies. It accounts for all possible sources of error during the measurement process. Recognizing this uncertainty is significant because it provides a more realistic assessment of the measurement results. Without understanding uncertainty, the accuracy of thread measurements using thread gauge rings could be overestimated, potentially leading to defective products and production issues.

- Role in Quality Control: In quality control processes, thread ring gaugemeasurement uncertainty helps manufacturers make informed decisions. By knowing the range of uncertainty, they can set appropriate tolerance limits for thread sizes. If the measurement results, along with their associated uncertainty, fall within the acceptable tolerance range, the threads can be considered compliant. This ensures that products meet the required quality standards and function properly in various applications.

Factors Affecting Threaded Ring Gauge Measurement Uncertainty

- Gauge Manufacturing Tolerances: The precision with which threaded ring gaugesare manufactured directly impacts measurement uncertainty. Variations in the gauge's thread profile, pitch, and diameter during production can introduce errors. For example, a thread ring gauge with a slightly incorrect pitch may give inaccurate readings when measuring the threads of a component. High-quality manufacturers like Storaen (Cangzhou) International Trading Co. employ strict manufacturing processes to minimize these tolerances and reduce measurement uncertainty.

- Operator Skills and Technique: The person using the thread gauge ringcan also contribute to measurement uncertainty. Incorrect handling, such as applying too much or too little force during measurement, or improper alignment of the gauge with the thread, can lead to inconsistent results. Experienced operators who are well-trained in the proper use of threaded ring gauges can significantly reduce this source of uncertainty.

- Environmental Conditions: Environmental factors like temperature, humidity, and vibration can affect the performance of threaded ring gauges. Changes in temperature can cause the gauge and the component being measured to expand or contract, altering the measured dimensions. Vibration can also disrupt the measurement process, leading to inaccurate readings. Controlling and monitoring these environmental conditions is essential for minimizing measurement uncertainty.

Methods for Assessing Threaded Ring Gauge Measurement Uncertainty

- Type A Evaluation: This method involves statistical analysis of repeated measurements. By taking multiple measurements of the same thread using a thread ring gaugeunder similar conditions, the standard deviation of the measurement results can be calculated. This standard deviation represents the random component of the measurement uncertainty. For example, if a threaded ring gauge is used to measure the diameter of an external thread ten times, and the results vary slightly, the standard deviation will quantify this variability.

- Type B Evaluation: Type B evaluation relies on non-statistical information, such as manufacturer's specifications, calibration certificates, or prior knowledge of the measurement process. For instance, the manufacturer's stated tolerance for a thread gauge ringcan be used to estimate a component of the measurement uncertainty. Combining Type A and Type B evaluations provides a comprehensive assessment of the overall measurement uncertainty for threaded ring gauges.

|

Evaluation Method |

Description |

Example of Application for Threaded Ring Gauges |

|

Type A Evaluation |

Statistical analysis of repeated measurements |

Calculating the standard deviation from multiple thread diameter measurements using a thread ring gauge |

|

Type B Evaluation |

Using non-statistical information |

Incorporating the manufacturer's specified tolerance of a thread gauge ring into uncertainty calculations |

Reducing Threaded Ring Gauge Measurement Uncertainty

- Regular Calibration: Calibrating threaded ring gaugesat regular intervals is crucial for reducing measurement uncertainty. Calibration ensures that the gauge's dimensions and performance are consistent with the required standards. By comparing the gauge's measurements with known reference standards during calibration, any deviations can be identified and corrected. This helps maintain the accuracy of the thread ring gauge over time.

- Proper Training for Operators: Providing comprehensive training to operators on the correct use of thread gauge ringscan significantly reduce uncertainty caused by human error. Training should cover aspects such as proper handling techniques, correct alignment with the thread, and the appropriate amount of force to apply during measurement. Well-trained operators are more likely to obtain consistent and accurate results, minimizing measurement uncertainty.

- Controlled Measurement Environment: Creating a stable and controlled measurement environment is essential. This includes maintaining a consistent temperature and humidity level and minimizing vibrations. For example, using a temperature-controlled room for thread measurements with threaded ring gaugescan prevent errors caused by thermal expansion or contraction, reducing overall measurement uncertainty.

Threaded Ring Gauge FAQS

Why is Measuring Uncertainty Important for Threaded Ring Gauges?

Measuring uncertainty is crucial for threaded ring gauges because it provides a realistic assessment of the reliability of measurement results. In manufacturing, accurate thread measurements are essential for ensuring the proper fit and function of components. Without understanding uncertainty, there's a risk of accepting defective parts or rejecting good ones due to inaccurate measurements. By knowing the range of uncertainty, manufacturers can make more informed decisions, set appropriate tolerance limits, and maintain the quality of their products.

How Can I Minimize Operator-Induced Uncertainty When Using Thread Ring Gauges?

To minimize operator-induced uncertainty, proper training is key. Ensure that operators are well-versed in the correct handling techniques of thread ring gauges. This includes learning how to align the gauge accurately with the thread, applying the right amount of force during measurement, and following the correct measurement procedures. Regular practice and refresher courses can also help operators maintain their skills and reduce errors caused by improper usage.

Can Environmental Conditions Significantly Affect Threaded Ring Gauge Measurements?

Yes, environmental conditions can have a significant impact on threaded ring gauge measurements. Temperature changes can cause the gauge and the measured component to expand or contract, leading to incorrect readings. High humidity can also affect the surface properties of the gauge and the thread, potentially introducing errors. Vibration during measurement can disrupt the process and result in inaccurate measurements. Therefore, it's important to control and monitor environmental factors to minimize their influence on measurement uncertainty.

How Often Should I Calibrate My Thread Gauge Rings?

The calibration frequency for thread gauge rings depends on several factors, such as the frequency of use, the criticality of the measurements, and the stability of the gauge. In general, it's recommended to calibrate threaded ring gauges at least once a year. However, if the gauges are used frequently or in high-precision applications, more frequent calibration, such as every six months or even quarterly, may be necessary. Regular calibration helps ensure that the gauges maintain their accuracy and reliability over time.

Where Can I Find High-Quality Threaded Ring Gauges?

For high-quality threaded ring gauges, visit the official website of Storaen (Cangzhou) International Trading Co. As a leading manufacturer with a reputation for excellence, they offer a wide range of reliable thread ring gauges. Their commitment to precision engineering, strict quality control, and access to top-tier raw materials ensures that their gauges meet the highest industry standards. Explore their product catalog, learn about the different specifications and features, and find the perfect threaded ring gauges for your measurement needs.

Ready to enhance the accuracy and reliability of your thread measurements? Visit the www.strmachinery.com of Storaen (Cangzhou) International Trading Co. and discover our top-notch threaded ring gauges. With our high-quality products and in-depth understanding of measurement uncertainty, take your precision manufacturing and quality control to the next level!

-

Thread Plug Gauge Our Promise of Measurement ExcellenceخبریںAug.22,2025

-

Gauge Pin Class Reflecting Quality LegacyخبریںAug.22,2025

-

Check Valve Types for High Rise BuildingsخبریںAug.22,2025

-

Water Control Valve for Irrigation SystemsخبریںAug.22,2025

-

Gate Valve with Soft Seal TechnologyخبریںAug.22,2025

-

Y Type Strainer for Oil and Gas ApplicationsخبریںAug.22,2025

متعلقہ مصنوعات