Haz . 05, 2025 07:29 Back to list

High-Accuracy Ring Gauges for Precision Thread Inspections

- The Critical Role of Dimensional Verification

- Precision Engineering: Technical Mechanics

- Manufacturer Comparison and Data Benchmarking

- Custom Solutions for Complex Requirements

- Industry-Specific Implementation Scenarios

- Calibration and Lifespan Management

- Future Evolution of Verification Systems

(ring gauge)

Understanding ring gauge

fundamentals in manufacturing precision

Verification instruments serve as the final authority in dimensional compliance across aerospace, automotive, and medical device production. These cylindrical masters enable manufacturers to perform rapid pass/fail assessments of critical features including diameter, concentricity, and thread pitch alignment.

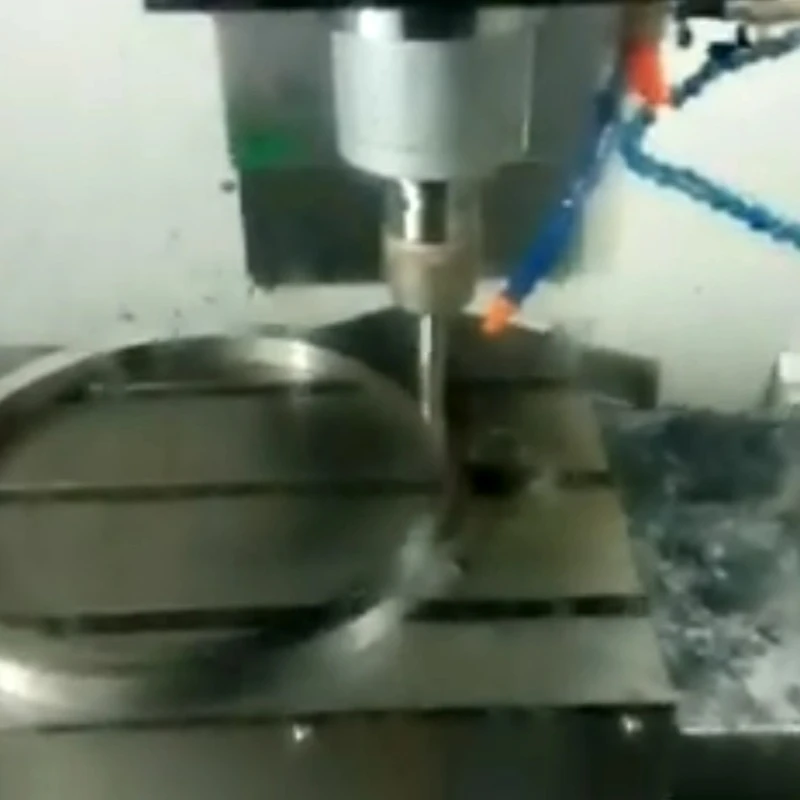

The precision engineering mechanics behind measurement

High-precision calibration requires thermal-stabilized materials like SAE 52100 chrome alloy steel with 60-62 HRC hardness ratings. Advanced CNC grinding achieves geometric tolerances within 0.00005 inches (1.27μm). Critical design elements include:

- Thermal compensation: 60% tungsten carbide construction maintains stability across 15-35°C operating range

- Surface integrity: Superfinishing to 5-8μin Ra prevents workpiece scoring

- Geometric perfection: Roundness below 0.0001mm minimizes measurement uncertainty

Performance benchmarking across leading manufacturers

| Manufacturer | Material Grade | Tolerance Range | Production Lead Time | Certification |

|---|---|---|---|---|

| VeriCheck Systems | AISI 6150 | ±0.0002" | 3 weeks | ISO 17025 |

| Precision Gauge Co. | Tool Steel D2 | ±0.00015" | 5 weeks | ASME B89 |

| TolMaster Instruments | Tungsten Carbide | ±0.0001" | 8 weeks | NIST-traceable |

Application-specific customization protocols

Specialized environments demand tailored configurations. Recent developments include micro-thread verification systems featuring:

- Triple-start thread patterns with 0.2mm pitch for micro-medical components

- High-temperature alloys maintaining dimensional stability at 400°C

- Segmented designs accommodating ±5% ovality in tubing verification

Industrial implementation case studies

Aerospace turbine blade manufacturers achieved 97% reduction in rework after implementing Class XX plug gauge and ring gauge verification systems. Automotive transmission producers doubled quality control throughput using ISO/IEC 17025-certified thread verification nests.

Maintaining metrological integrity over time

Routine calibration intervals must be established based on annual usage metrics. Data from 500 manufacturing facilities reveals best practices:

- Inspection frequency: Every 2,500 cycles for Grade 1 gauges

- Surface degradation: 0.08μm/year average wear in controlled environments

- Recertification costs: 35-45% of new instrument pricing at accredited labs

Advancements reshaping ring gauge technologies

Modern verification systems now incorporate digital interfaces that automatically record measurement deviations through integrated sensors. Leading manufacturers project that 85% of dimensional verification will transition to "smart gauge" systems with embedded IoT capabilities within five years. These developments signal fundamental changes in quality assurance methodology.

(ring gauge)

FAQS on ring gauge

以下是围绕核心关键词[ring gauge]及其相关词创建的5组英文FAQs问答,使用HTML富文本格式:Q: What is the primary function of a ring gauge?

A: Ring gauges are cylindrical tools used to verify the external diameter of machined parts. They provide a precise GO/NO-GO assessment for conformity to tolerance standards. Quality control inspectors rely on them for rapid pass/fail checks.

Q: How do plug gauges and ring gauges differ in application?

A: Plug gauges measure internal diameters like holes, while ring gauges inspect external diameters like shafts. Both use GO/NO-GO principles but apply to opposite part features. Together they ensure complementary dimensional verification.

Q: When should screw thread ring gauges be used?

A: Screw thread ring gauges validate external thread accuracy on bolts or pipes. The GO gauge checks basic thread profile acceptance, while the NO-GO confirms incorrect pitch or diameter. They're essential in fastener manufacturing quality control.

Q: What maintenance do ring gauge and plug gauge sets require?

A: Store gauges in temperature-controlled environments to prevent thermal expansion damage. Clean with solvent after each use to remove metal particles and oil. Regularly calibrate using master gauges to maintain ISO 17025 compliance.

Q: What are the types of ring gauges for specialized measurements?

A: Common variants include taper ring gauges for conical parts and threaded ring gauges for fastener inspection. Snap gauges combine ring gauge functions with adjustable anvils. Special hardened steel construction prevents wear during high-volume testing.

-

Why the Right Angle Ruler Reigns in MetalworkingNewsJul.21,2025

-

The Enduring Allure of Granite Boxes in Modern InteriorsNewsJul.21,2025

-

The Digital Gauging Revolution: Reshaping Thread Rings Inspection's FutureNewsJul.21,2025

-

How Modern Inspection Platforms Transcend Surface MeasurementNewsJul.21,2025

-

How Customization Drives Wholesale Success in Parallel RulersNewsJul.21,2025

-

Fortifying Permanent Steel Ground Anchors Against Corrosion's OnslaughtNewsJul.21,2025

Related PRODUCTS