Jul . 29, 2025 09:55 Sanawa dolan

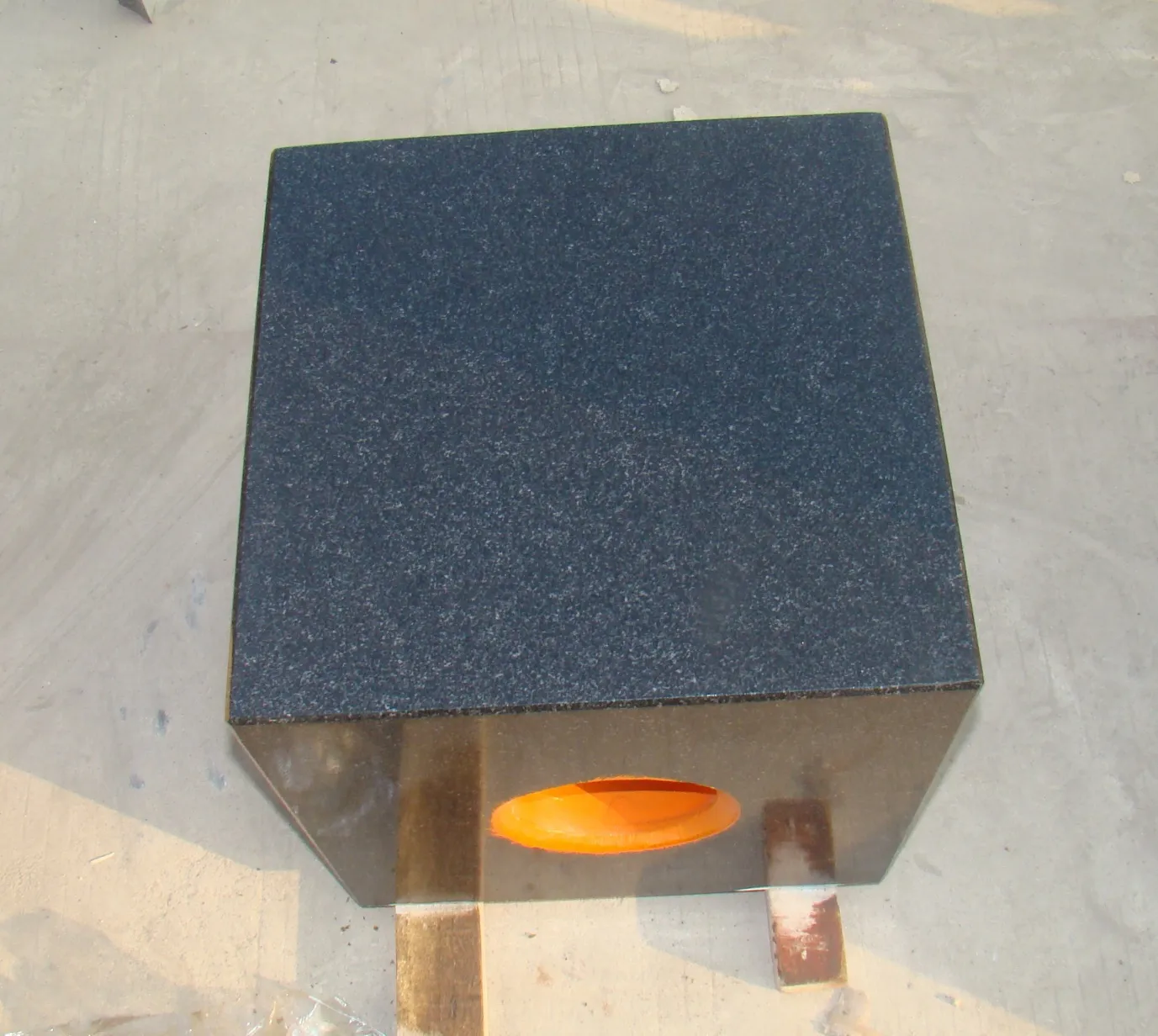

Granite Box Maintains Precision Flatness

In the realm of precision engineering and manufacturing, the choice of materials directly impacts performance, accuracy, and reliability. Among the most trusted materials in these fields are granite and marble, celebrated for their unique physical properties that make them indispensable in various industrial and technical applications. At the heart of this trust lie three key components: the granite box, the block of granite, and the marble box. These products, derived from natural stone, offer a blend of stability, durability, and precision that synthetic materials often struggle to match. Whether used in machinery setup, measurement tasks, or specialized engineering projects, understanding their characteristics, uses, and maintenance is essential for maximizing their value. This article delves into the world of these stone-based products, exploring their properties, applications, and frequently asked questions to provide a comprehensive guide for professionals and enthusiasts alike.

Understanding the Core Properties of a Granite Box

A granite box is more than just a container; it is a precision tool engineered to meet the strict demands of accuracy-critical environments. What sets a granite box apart is its inherent material properties, rooted in the natural composition of granite. Granite, an igneous rock formed from the slow crystallization of magma, boasts a dense, uniform structure that resists deformation under pressure or temperature changes. This dimensional stability is paramount in applications where even the smallest shift can compromise results, such as in metrology, tooling, or machinery calibration.

Another key property of a granite box is its exceptional surface finish. Through careful processing, the surface of a granite box achieves a smoothness that minimizes friction and provides a consistent reference plane. This smoothness also makes it resistant to wear, ensuring that the box maintains its precision over years of use. Additionally, granite is naturally resistant to corrosion, chemicals, and moisture, making the granite box suitable for use in harsh industrial environments where exposure to fluids or contaminants is common. Unlike metal alternatives, which may rust or warp, a granite box retains its integrity, offering long-term reliability that reduces the need for frequent replacements.

Exploring the Versatile Applications of a Block of Granite

A block of granite is a foundational material in numerous industries, valued for its strength, stability, and adaptability. Its versatility stems from its ability to be shaped, processed, and integrated into a wide range of systems and tools. Here are some of the primary applications where a block of granite shines:

- Precision Machinery Bases: A block of graniteis often used as a base for high-precision machinery such as lathes, milling machines, and coordinate measuring machines . Its stability dampens vibrations, ensuring that the machinery operates with minimal movement, thus enhancing accuracy in manufacturing and inspection processes.

- Surface Plates and Reference Surfaces: When cut and polished, a block of granitebecomes an ideal surface plate for measuring, marking, or testing components. Its flatness serves as a reliable reference point, ensuring that measurements are consistent and accurate across different tasks.

- Calibration Tools: In calibration laboratories, a block of graniteis used to create standard reference tools. Its dimensional stability allows for the precise calibration of gauges, micrometers, and other measuring instruments, ensuring that they meet industry standards.

- Optical and Scientific Instruments: The vibration-damping properties of a block of granitemake it valuable in optical setups, telescopes, and scientific equipment where stability is critical for clear observations or precise experiments.

- Custom Components: A block of granitecan be machined into custom shapes to fit specific industrial needs, such as guides, supports, or fixtures. Its adaptability allows engineers to design solutions that leverage its natural strengths in unique applications.

Why a Marble Box Stands Out in Precision Engineering

While granite is renowned for its strength, the marble box offers a distinct set of advantages that make it a preferred choice in certain precision engineering scenarios. Marble, a metamorphic rock formed from limestone subjected to heat and pressure, has a fine-grained structure that results in an exceptionally smooth surface. This smoothness is particularly beneficial in applications where components slide or move across the surface of the box, as it reduces friction and wear, ensuring consistent performance.

A marble box also stands out for its aesthetic appeal, which can be an advantage in settings where equipment visibility matters, such as in research facilities, quality control labs, or customer-facing industrial spaces. Beyond appearance, marble’s natural composition provides good vibration damping properties, similar to granite, making the marble box effective at minimizing the impact of external vibrations on sensitive measurements or processes.

Additionally, marble is easier to polish to a high sheen compared to some types of granite, which can be beneficial for applications where a reflective or visually pristine surface is required. While marble may be slightly less dense than granite, its durability is still impressive, and a well-maintained marble box can provide reliable service in precision environments for many years. Its unique combination of functionality and aesthetics makes the marble box a versatile option for engineers and technicians seeking both performance and visual appeal.

Essential Maintenance Practices for a Granite Box

To ensure that a granite box retains its precision and longevity, proper maintenance is essential. While granite is inherently durable, neglecting basic care can lead to surface damage, reduced accuracy, or premature wear. The following maintenance practices will help preserve the performance of your granite box:

|

Maintenance Step |

Description |

Purpose |

|

Regular Cleaning |

Wipe the surface with a soft, lint-free cloth dampened with mild soap and water. Avoid using abrasive cleaners, harsh chemicals, or scouring pads. |

Prevents the buildup of dust, debris, or contaminants that can scratch the surface or interfere with measurements. |

|

Climate Control |

Store or use the granite box in a environment with stable temperature and humidity levels. Avoid placing it near heat sources, air vents, or areas with extreme temperature fluctuations. |

Maintains the granite box’s dimensional stability, as sudden temperature changes can cause minor expansion or contraction. |

|

Impact Prevention |

Handle tools and components carefully around the granite box. Avoid dropping heavy objects or striking the edges or surface with hard materials. |

Prevents chips, cracks, or dents that can compromise the box’s flatness and structural integrity. |

|

Periodic Inspection |

Check the granite box regularly for signs of damage, such as chips, cracks, or uneven surfaces. Pay special attention to edges and corners, which are more prone to wear. |

Allows for early detection of issues, enabling timely repairs to prevent further damage. |

|

Professional Servicing |

For high-use granite boxes, schedule annual professional polishing or resurfacing by experienced technicians. |

Restores the surface finish, ensuring that the box continues to provide accurate reference points. |

By following these practices, you can extend the lifespan of your granite box and ensure that it remains a reliable tool in your precision workflows.

FAQS about Granite Box, Block of Granite, and Marble Box

What makes a Granite Box suitable for precision measurement tasks?

A Granit gutusy is ideal for precision measurement tasks due to its inherent dimensional stability, which resists deformation from temperature changes, pressure, or vibration. Its smooth, wear-resistant surface provides a consistent reference plane, ensuring accurate measurements. Additionally, granite’s resistance to corrosion and chemicals means the Granit gutusy maintains its integrity even in harsh industrial environments, making it a trusted tool for metrology and calibration.

How is a Block of Granite processed for industrial applications?

A Block of Granite undergoes several processing steps to prepare it for industrial use. First, raw granite is quarried and cut into rough blocks. These blocks are then shaped using precision saws to achieve the desired dimensions. Next, the surface is ground to remove imperfections and create a flat base. Finally, the Block of Granite is polished to enhance smoothness, ensuring it meets the strict flatness and finish requirements of applications like machinery bases, surface plates, or calibration tools.

Can a Marble Box be customized for specific engineering needs?

Yes, a Marble Box can be customized to meet specific engineering needs. Manufacturers can adjust the size, shape, and surface finish of the Marble Box to fit unique applications, such as custom fixtures, display components, or specialized measurement tools. The fine-grained structure of marble allows for detailed machining, making it possible to create intricate designs while maintaining the smooth surface and vibration-damping properties that make the Marble Box valuable in precision settings.

What are the key differences between a Granite Box and a Marble Box in terms of performance?

The key differences between a Granit gutusy and a Marble Box lie in their material properties. A Granit gutusy is denser and more resistant to impact and wear, making it ideal for high-stress industrial environments. It also offers superior dimensional stability under extreme temperatures. A Marble Box, while still durable, has a finer grain structure that results in a smoother, more polished surface, making it suitable for applications where aesthetics or reduced friction are priorities. Marble also dampens vibrations effectively but may be slightly less resistant to heavy impacts than granite.

How do I ensure the long-term durability of a Block of Granite used in machinery?

To ensure the long-term durability of a Block of Granite in machinery, follow these steps: store it in a climate-controlled environment to prevent temperature-related expansion or contraction; clean it regularly with mild soap and water to avoid debris buildup; avoid exposing it to harsh chemicals or abrasive materials that can damage the surface; inspect for chips or cracks periodically and address any damage promptly; and use protective covers when the Block of Granite is not in use to shield it from dust, impacts, or environmental contaminants. These practices help maintain the Block of Granite’s structural integrity and performance over time.

At [Storaen (Cangzhou) International Trading Co], we take pride in crafting high-quality granite box, block of granite, and marble box solutions tailored to the unique needs of precision industries. Our products are engineered with meticulous attention to detail, leveraging the natural properties of granite and marble to deliver reliability, accuracy, and longevity. We invite you to visit our website to see our granite box, block of granite, and marble box products in person—experience their precision firsthand, discuss your specific requirements with our expert team, and discover how our stone-based solutions can elevate your operations. Whether you’re in manufacturing, metrology, or engineering, we’re here to provide the tools you need to achieve excellence.

-

Thread Plug Gauge Requires Careful HandlingHabarlarJul.29,2025

-

Surface plate calibrationHabarlarJul.29,2025

-

Ring Gauge Ensures Machining AccuracyHabarlarJul.29,2025

-

Pad Iron Reinforces Anchor PointsHabarlarJul.29,2025

-

Ground anchor stabilizes embankmentsHabarlarJul.29,2025

-

Granite Box Maintains Precision FlatnessHabarlarJul.29,2025

Baglanyşykly önümler