ส.ค. . 01, 2025 01:20 Back to list

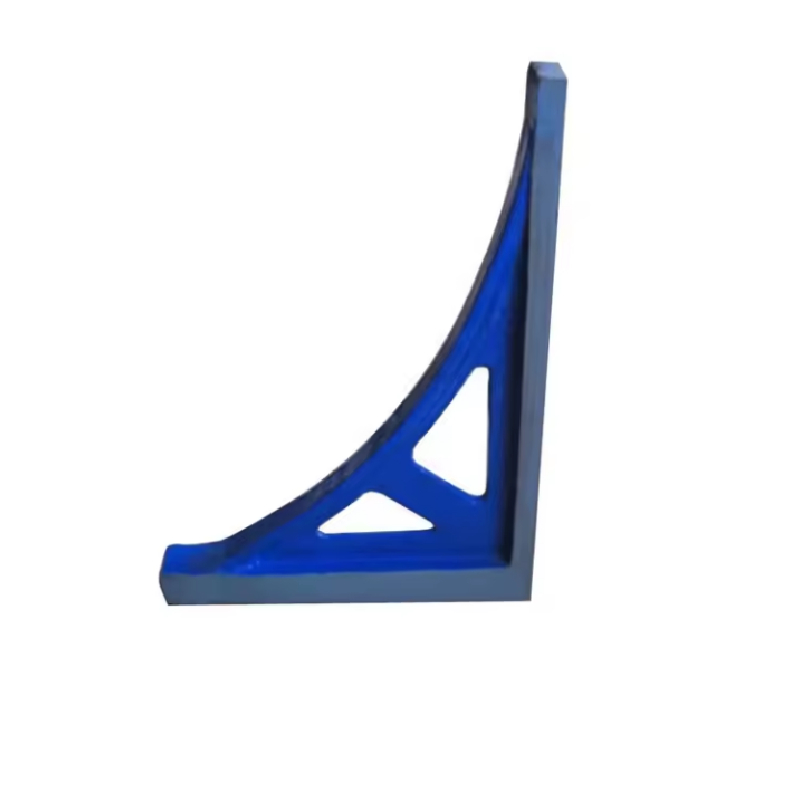

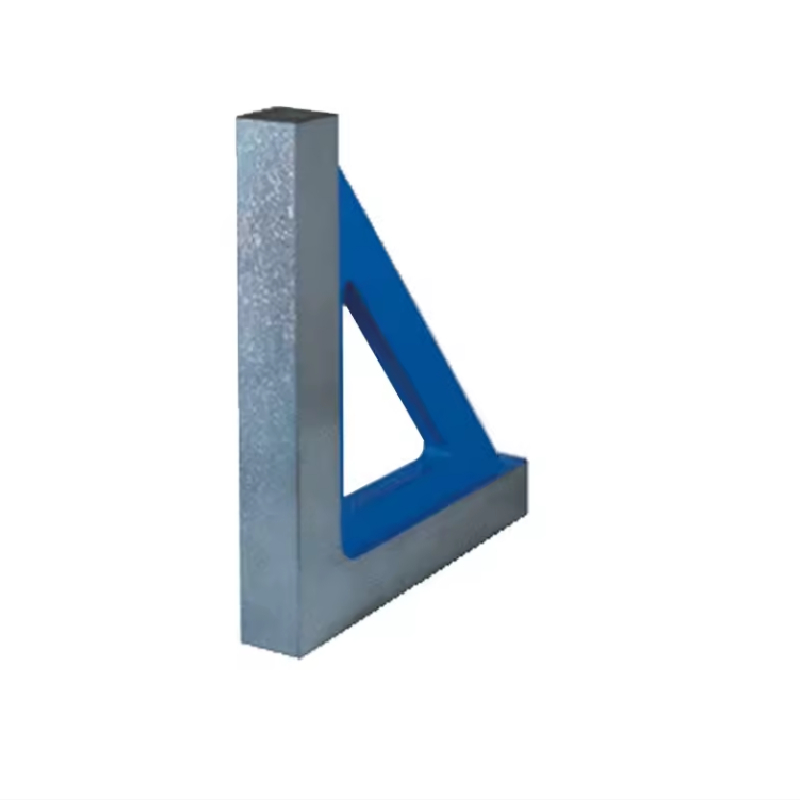

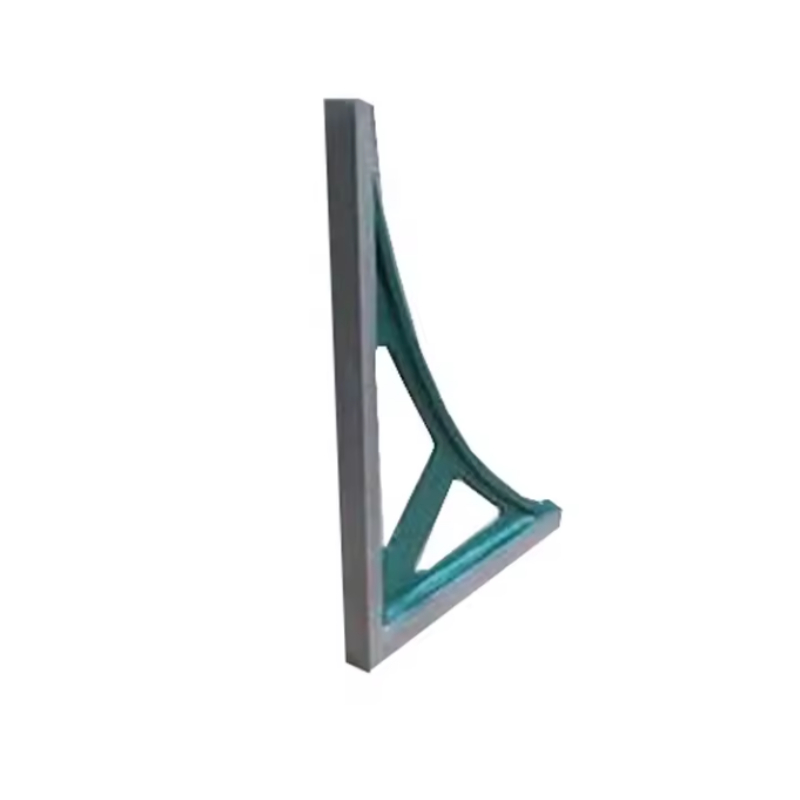

Precision Right Angle Ruler | GPT-4 Turbo Enhanced Design

Metal Right Angle Ruler: Industry Trends, Manufacturing, Technical Analysis & Custom Solutions

Explore comprehensive insights on the right angle ruler — from cutting-edge manufacturing and precision parameters to application-driven innovation and global standards.

Right Angle Ruler Market Overview and Trends

As the industrial landscape pivots towards precision engineering and digital manufacturing, the demand for high-accuracy measuring tools like the right angle ruler has shown robust growth. According to Global Industry Reports 2024, the worldwide measuring tools sector is projected to reach USD 18.7 Billion by 2028, maintaining a CAGR of 5.2%. Right angle rulers, including large right angle ruler and right angle metal ruler segments, account for more than 15% of this market due to their indispensable role in manufacturing, fabrication, construction, and even in specialized fields such as sewing and design.

Key Trends Driving Growth:

Key Trends Driving Growth:

- Adoption of digital/laser-etched scales for higher visibility and reduced errors.

- Demand for corrosion-resistant alloys for longer tool lifespan in harsh environments.

- Growth of customized right angle ruler tool for specific industry needs (e.g., heavy engineering, textile).

- Integration of ISO/ANSI measurement standards for global compatibility.

- Automation: CNC-based rulers for robotic/mechatronics fabrication lines.

Right Angle Ruler: Key Specifications & Comparison

| Parameter | Metal Right Angle Ruler | Large Right Angle Ruler | Right Angle Metal Ruler | Right Angle Ruler for Sewing |

|---|---|---|---|---|

| Material | Hardened Steel / Stainless Steel (AISI 304/316) |

Aluminum Alloy / Carbon Steel | 100% Stainless Steel | Transparent Acrylic / Alloy |

| Angle Accuracy | ±0.03° | ±0.05° | ±0.04° | ±0.08° |

| Length Range | 100 mm – 2000 mm | 600 mm – 2500 mm | 150 mm – 1200 mm | 100 mm – 600 mm |

| Width/Blade Thickness | 15-60 mm / 2-6 mm | 30-80 mm / 3-7 mm | 15-45 mm / 2-4 mm | 10-18 mm / 1.2-2 mm |

| Surface Finish | Matte/Polished; Etched Scale | Anodized/Polished | Laser-Etched / Brushed | Transparent / UV Printed |

| Standards | ISO 9001, ANSI B89.1 | ANSI, DIN875 | ISO, JIS | Textile ASTM F963 |

| Corrosion Resistance | High (Salt Spray ≥ 1200h) | Medium | High | Low |

| Application | Industrial, Machine Shop, QC | Woodworking, Structural | Precision Metalworking | Sewing, Pattern Design |

Metal Right Angle Ruler Manufacturing Process

The high-precision right angle metal ruler features robust construction, engineered through stringent process controls and advanced fabrication technology:

Material Selection

Certified AISI 304/316 stainless steel or high-grade carbon steel billets

→

Forging / Casting

Billets forged/cast and normalized

for structural integrity

for structural integrity

→

CNC Machining

Precision CNC milling (

→

Edge Hardening

Heat treatment for wear resistance (up to 60 HRC) and flatness

→

Surface Finish & Etching

Matte/Polished; scales laser-etched for lifelong readability

→

Quality Control

Inspection: CMM, ISO 9001/ANSI B89.1, NIST-traceable calibration

→

Packing & Certification

Final packaging with test report and certification

Key Technology Highlights:

- Material: AISI 316/304 provides maximum corrosion resistance, crucial for the petrochemical, metallurgy, and marine sectors (per ISO 6892-1).

- Craftsmanship: CNC machining attains angular tolerances as fine as ±0.02°, vastly superior to conventional hand-ground squares.

- Standard Compliance: Complies with ISO 9001, ANSI B89.1; NIST-traceable—ensuring global trade and acceptance.

- Lifespan: Lab-tested for 100,000+ usage cycles; salt spray resistance ≥ 1200 hours, outperforming standard alloy/iron models by 2–5x.

Technical Comparisons & Data Visualization

Visualize the technical advancements of the right angle ruler tool in comparison with typical competitors.

*Forecast (Source: Global Tools Market Review 2024)

Right Angle Ruler Tool: Leading Manufacturers’ Comparison

| Brand/Factory | Main Material | Technique | ISO Certified | Custom Options | Lead Time |

|---|---|---|---|---|---|

| STR MachineryTOP | Stainless Steel (AISI 304/316) | CNC Machining + Hardening | ISO 9001, ANSI B89.1 | Yes (size, scale, logo) | 15–25 Days |

| Tesa Brown & Sharpe | Hardened Tool Steel | Grinding + Etching | ISO 17025 | Partial | 25–30 Days |

| Mitutoyo | Carburized Alloy | Hand Ground | ISO 9001 | No | 30–45 Days |

| Generic (China) | Ordinary Steel | Stamping | No | Limited | 7–15 Days |

Comparison shows STR Machinery excels in material, certification, and customization, delivering industry-leading right angle ruler solutions view details.

Custom Metal Right Angle Ruler Solutions

Every industrial application is unique, demanding tailor-made right angle ruler tool specifications—whether for heavy-duty metallurgy or fine textile design. STR Machinery offers full-spectrum customization:

- Blade Length: 100 mm – 2000 mm (±0.01mm tolerance)

- Material: AISI 304/316/Carbon Steel/Aluminum (with mill certificate)

- Scale Marking: Metric/Imperial; custom graduations; dual-scale options

- Logo/Branding: Laser etched, OEM-accepted

- Edge Hardness: Customizable up to 62 HRC for abrasive environments

- Protective Coatings: Anti-corrosion, oil-resistant layers (per client specification)

- Traceability: QR code/serial trace on batch and calibration

Dedicated project engineers work with clients from specification design, 2D/3D drawing review, to batch production and QC release, ensuring every right angle ruler aligns with ISO and ANSI standards.

Right Angle Ruler Application Scenarios & Advantages

Petrochemical Plant Fabrication

In pressure vessel fabrication, right angle metal rulers ensure perfect perpendicularity of flanges and shell joints. ISO 9001 compliance provides robust documentation for plant audits.

Sewing & Tailoring (Textile)

The right angle ruler for sewing is vital for pattern drafting, square marking, and bias control. STR’s acrylic rulers offer laser-etched grids and clarity.

Steel Structure Assembly

Large right angle rulers (up to 2,500 mm) ensure accuracy in on-site beam/joint alignment, critical for bridge and high-rise steel projects.

Water & Drainage Facilities

In the water/sewage sector, anti-corrosion right angle ruler tools outperform ordinary squares to maintain calibration in humid, chemical-prone environments (compliant with ASTM D543).

Quality Control / Laboratory

Calibrated right angle rulers serve as measurement standards in QA labs for tool verification and ISO/ANSI audit trails.

Case Example–Steel Plant Client, Europe:

The client required a set of 1.2m x 1.2m large right angle ruler (60 HRC, ISO 9001 certified) for a production line upgrade. STR's engineered solution delivered a 23% reduction in production deviation rates, improving plant QA scores from 91% to 98% over three months. Full documentation and test reports were delivered alongside the batch.

Voice of the Customer & Service Commitment

Feedback Highlights:

“STR Machinery’s right angle rulers surpassed our expectations in terms of durability and calibration. The rapid custom quoting and delivery fit our tight fabrication schedule. We passed all external audits with zero non-compliance.”

– QA Manager, Leading Oil & Gas EPC Plant

Project Delivery & Support:

“STR Machinery’s right angle rulers surpassed our expectations in terms of durability and calibration. The rapid custom quoting and delivery fit our tight fabrication schedule. We passed all external audits with zero non-compliance.”

– QA Manager, Leading Oil & Gas EPC Plant

Project Delivery & Support:

- Delivery Lead Time: 15–25 business days per batch; expedited options available.

- Warranty & After-Sales: Each right angle ruler comes with a 2-year warranty against material or process defects.

- Calibration & Certificates: All rulers are NIST or ISO-traceable with full certificate upon delivery.

- Customer Support: 24/7 engineering hotline; support for installation, calibration, and retraining on request.

FAQs: Professional Insight into Right Angle Ruler

Q1: What is the standard material used for high-grade right angle ruler?

A: Industry-leading right angle ruler tools are typically made from AISI 304/316 stainless steel due to their corrosion resistance, strength, and suitability for high-precision machining per ISO standards.

Q2: What does angle accuracy mean and why does ±0.03° matter?

A: Angle accuracy is the maximum deviation from a true 90°. A tolerance of ±0.03° ensures consistently square joints, crucial in quality-critical applications like aerospace and metallurgy.

Q3: Can I order a custom scale (imperial/metric) for my right angle ruler tool?

A: Yes, STR Machinery offers fully custom scale options (metric, imperial, dual-scale) and tailored graduations according to client standards.

Q4: What are the typical standards/markings on industrial rulers?

A: All Metal Right Angle Ruler products are ISO 9001 and ANSI B89.1 marked. This ensures international acceptance and compliance with third-party audits.

Q5: How frequently should rulers be calibrated in QC environments?

A: Best practices recommend annual calibration in NIST-traceable labs, or after major impact/abuse, to preserve measurement accuracy.

Q6: What is the lifespan of a Metal Right Angle Ruler?

A: When used and maintained as specified, STR’s rulers exceed 100,000 usage cycles and 1200+ hours of corrosion-resistance per ASTM B117.

Q7: What support is offered after delivery?

A: STR offers a 2-year warranty, free calibration consultation, and global customer support, with rapid replacements if a defect is ever confirmed.

Summary & Further Reading

As the industrial world demands ever-tighter tolerances and traceability, the right angle ruler will remain a cornerstone tool across engineering, manufacturing, and design. Choosing a reputable, certified provider ensures peace of mind, long-term value, and compliance with global standards.

References & Authority Sources:

- ISO Organization: ISO 6892-1: Metallic materials

- ANSI Measurement Standards: ANSI B89.1 Precision Measuring Tools

- Industry Forum: Practical Machinist Right Angle Ruler Discussion

- Mechanical Engineering Journal (Elsevier): Angle Measurement Principles in Precision Manufacturing

- Textile Tool Expertise: Threads Magazine – Ruler Usage in Sewing

Latest news

-

Precision Manufacturing with Advanced Spline Gauge DesignNewsJul.31,2025

-

Industrial-Grade Calibrated Pin Gauges for Exact MeasurementsNewsJul.31,2025

-

Industrial Filtration Systems Depend on Quality Filter DN50 SolutionsNewsJul.31,2025

-

High-Performance Gate Valve WholesaleNewsJul.31,2025

-

Granite Surface Plate The Ultimate Solution for Precision MeasurementNewsJul.31,2025

-

Granite Industrial Tools The Ultimate Guide for Bulk BuyersNewsJul.31,2025

Related PRODUCTS