Januari . 31, 2025 03:08 Back to list

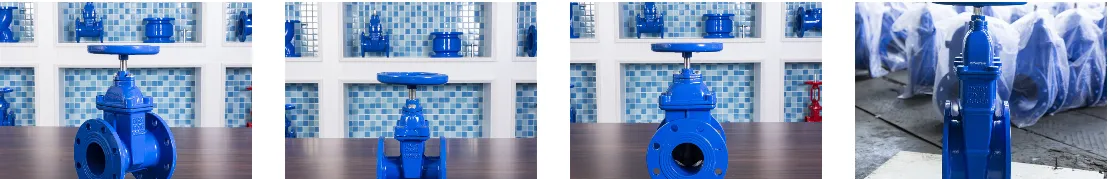

butterfly valve types

When it comes to industrial applications involving fluid control, the butterfly valve 24 inch size holds significant importance due to its large specifications, efficiency, and optimal performance for various sectors, including oil and gas, water treatment, and manufacturing. With decades of engineering innovation and operational enhancements, the butterfly valve, particularly the 24-inch variant, has become synonymous with reliability and functionality.

Furthermore, trustworthiness in the performance of 24-inch butterfly valves comes from rigorous testing and quality assurance processes. Manufacturers routinely subject their valves to hydrostatic and pneumatic testing to verify leakage rates and pressure tolerance. This rigorous testing framework ensures that each valve can handle the demands of harsh industrial environments while providing consistent performance over its operational lifespan. Expertise in the field also necessitates an understanding of the butterfly valve’s adaptability to advanced automation and control systems. As industries move towards smarter, more autonomous operations, 24-inch butterfly valves are frequently integrated with actuators and sensors that allow for remote monitoring and control. This capability not only enhances efficiency and precision in fluid management but also facilitates predictive maintenance strategies, resulting in reduced operational disruptions and cost savings. From a professional standpoint, the continual evolution of 24-inch butterfly valves demonstrates a commitment to innovation and improvement within the industry. By incorporating user feedback and adopting new materials and technologies, manufacturers strive to produce valves that are lighter, more resilient, and versatile, thus addressing the diverse requirements of different sectors. In conclusion, the 24-inch butterfly valve is not just a component but a testament to decades of engineering excellence and innovation. Its significance in various industries cannot be overstated, as it represents a convergence of reliability, efficiency, and cutting-edge technology. Whether you are an engineer, operator, or procurement specialist, understanding the complex balance of materials, design, and operational expertise that defines these valves is crucial for making informed decisions that ensure optimal system performance. With proper care and precise application, the 24-inch butterfly valve remains an indispensable asset in the ever-evolving landscape of industrial fluid control.

Furthermore, trustworthiness in the performance of 24-inch butterfly valves comes from rigorous testing and quality assurance processes. Manufacturers routinely subject their valves to hydrostatic and pneumatic testing to verify leakage rates and pressure tolerance. This rigorous testing framework ensures that each valve can handle the demands of harsh industrial environments while providing consistent performance over its operational lifespan. Expertise in the field also necessitates an understanding of the butterfly valve’s adaptability to advanced automation and control systems. As industries move towards smarter, more autonomous operations, 24-inch butterfly valves are frequently integrated with actuators and sensors that allow for remote monitoring and control. This capability not only enhances efficiency and precision in fluid management but also facilitates predictive maintenance strategies, resulting in reduced operational disruptions and cost savings. From a professional standpoint, the continual evolution of 24-inch butterfly valves demonstrates a commitment to innovation and improvement within the industry. By incorporating user feedback and adopting new materials and technologies, manufacturers strive to produce valves that are lighter, more resilient, and versatile, thus addressing the diverse requirements of different sectors. In conclusion, the 24-inch butterfly valve is not just a component but a testament to decades of engineering excellence and innovation. Its significance in various industries cannot be overstated, as it represents a convergence of reliability, efficiency, and cutting-edge technology. Whether you are an engineer, operator, or procurement specialist, understanding the complex balance of materials, design, and operational expertise that defines these valves is crucial for making informed decisions that ensure optimal system performance. With proper care and precise application, the 24-inch butterfly valve remains an indispensable asset in the ever-evolving landscape of industrial fluid control.

Next:

Latest news

-

Why Metric Trapezoidal Thread is Ideal for Precision Motion ControlNewsAug.05,2025

-

The Unique Properties of a Block of Granite for Industrial UseNewsAug.05,2025

-

The Role of Flanged Y Strainers in Preventing Pipeline ClogsNewsAug.05,2025

-

The Importance of Regular Calibration for Master Ring GagesNewsAug.05,2025

-

How a Cast Iron Surface Table Enhances Accuracy in ManufacturingNewsAug.05,2025

-

Comparing Different Check Valve Types for Optimal Flow ControlNewsAug.05,2025

Related PRODUCTS