Jul . 18, 2025 14:31 Balik deui ka daptar

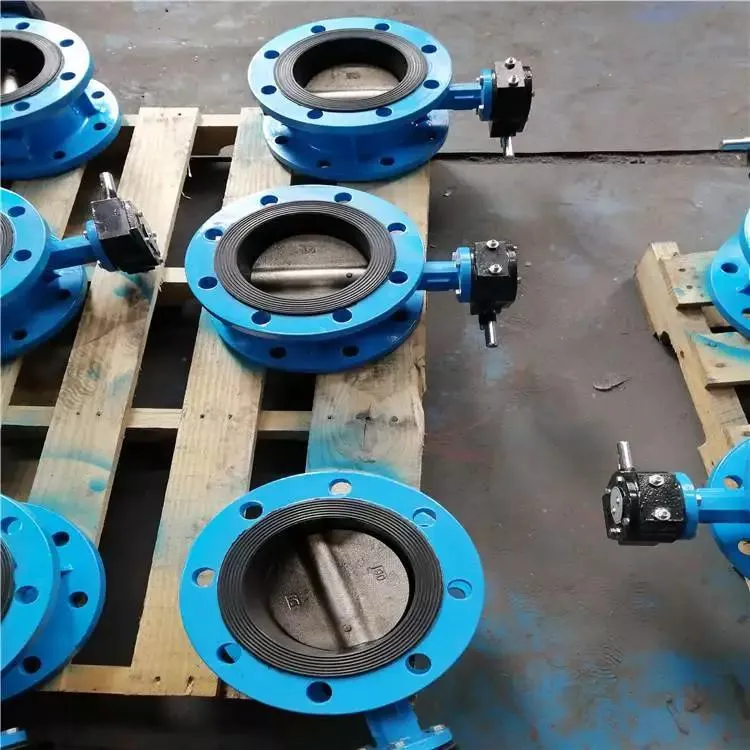

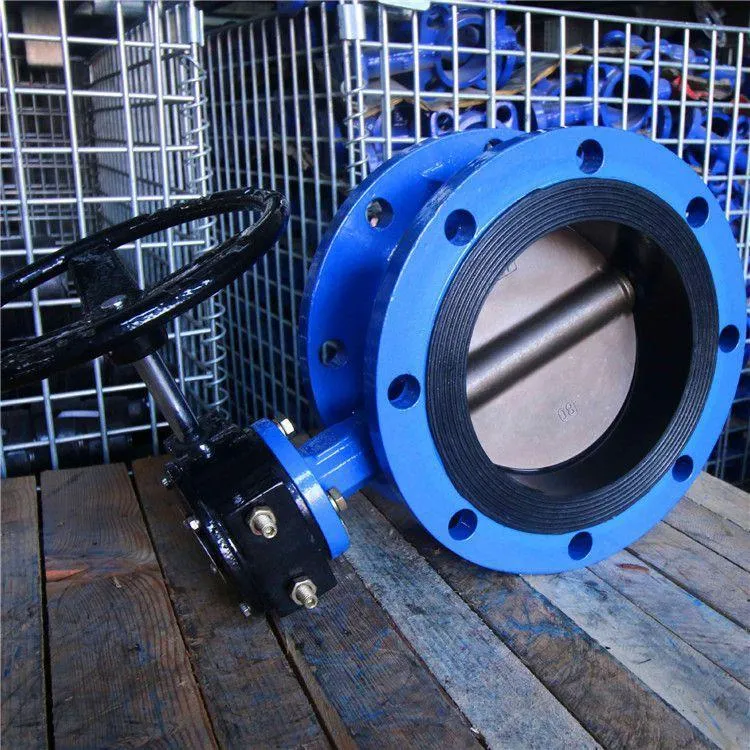

Butterfly Valve Types Standards

As a wholesaler, understanding standards is key to choosing flow control tools. The butterfly valve and its types, covered by strict standards, meet diverse industrial needs. Alongside butterfly valve types and butterfly valves for sale, these standards guide reliability. How Storaen (Cangzhou) International Trading Co.—a beacon of excellence in Botou, China—delivers compliant products.

Butterfly Valve Types Classification Standards

- Butterfly valve types are classified by structure: center sealed, single, double, triple eccentric, each based on butterfly plate position to suit specific sealing needs in different pipeline setups.

- By sealing material: soft seal (non-metallic) works well for water systems where tight shutoff is key; hard seal (metal) handles high temps or abrasive media effectively in tough environments.

- Operating pressure ranges from vacuum to ultra-high, precisely matching butterfly valveto the unique demands of various systems, ensuring safe and efficient operation.

Core Design Standards for High Performance Butterfly Valve

- High-performance butterfly valvemeets strict standards for sealing, materials, and actuation. Double eccentric designs reduce friction significantly, ensuring tight seals even at high pressures common in industrial pipelines.

- Triple eccentric models enable reliable metal-to-metal sealing, meeting rigorous standards for extreme temps and highly abrasive media in tough industrial settings like mining or power plants.

- Butterfly valve typesuse certified materials like cast iron and steel, each tested for optimal temperature resistance and corrosion prevention to extend service life in harsh conditions—aligning with Storaen’s commitment to precision engineering.

Quality Assurance Standards for Butterfly Valves for Sale

- Butterfly valves for salepass strict tests: hydrostatic checks verify zero leakage under pressure, and cycle tests ensure durability through thousands of operations in real-world use over extended periods.

- Storaen, rooted in Botou’s casting hub, leverages top-tier raw materials and skilled labor to adhere to these standards. Their butterfly valve typesundergo thorough testing, embodying the company’s unwavering commitment to quality and stringent control measures.

Butterfly Valve Application Standards Across Industries

- Butterfly valvestandards ensure proper use: soft seal types meet strict hygiene standards, making them ideal for water treatment facilities where purity is critical for public health.

- Stainless steel butterfly valvemodels comply with strict corrosion standards, perfect for chemical processing where harsh substances can damage lesser materials over time.

- Triple eccentric types meet high-temp standards, performing reliably in power plant flue gas ducts with extreme heat conditions that would degrade other valve types quickly.

- Storaen’s versatility shines here—their portfolio, including cast iron welding platforms and measuring tools, extends to butterfly valve typestailored to global industrial needs, thanks to agility in meeting market demands.

|

Standard Type |

Key Requirements |

|

Structural |

Eccentric design, sealing mechanism, connection type (wafer, flanged) |

|

Bahan |

Corrosion resistance, temperature tolerance, strength |

|

Performance |

Leakage rate, pressure rating, cycle life |

|

Testing |

Hydrostatic, cycle, material composition tests |

Butterfly Valve FAQS

How do standards classify butterfly valve types?

Standards classify butterfly valve types by structure, sealing material, pressure, and temperature, ensuring each type is perfectly suited to specific applications, making selection straightforward for users across different industries.

Why are material standards important for butterfly valve?

Material standards are crucial for butterfly valve as they ensure the valve can withstand varying temps, corrosive substances, and pressure, guaranteeing long-term performance, durability, and safe operation in all working conditions.

What testing standards apply to butterfly valves for sale?

Butterfly valves for sale undergo hydrostatic tests to check for leakage under pressure, cycle tests to assess durability through repeated use, and material tests to verify quality, all ensuring they meet necessary performance and safety standards.

How do application standards affect butterfly valve types?

Application standards dictate features for butterfly valve types: water treatment needs soft seals for hygiene, while power plants require high-temp resistance, ensuring each valve works optimally in its intended role.

How does Storaen ensure their butterfly valve meets standards?

Storaen ensures butterfly valve meets standards through strict material selection, adherence to design specs, and rigorous testing—backed by their legacy of excellence, innovation, and customer focus. Their location in Botou’s casting hub further strengthens access to premium resources.

For butterfly valve, butterfly valve types, and butterfly valves for sale meeting global standards, trust Storaen (Cangzhou) International Trading Co. Welcome to visit us—where quality, precision, and sustainability converge.

-

Right Angle Ruler Innovations in Measuring ToolsWartaJul.18,2025

-

Parallel Ruler Maintenance for Long-Term AccuracyWartaJul.18,2025

-

Magnetic V Block 4 Inch Cost Effectiveness AnalysisWartaJul.18,2025

-

Internal Thread Gauge Innovations for Faster InspectionWartaJul.18,2025

-

Ground Anchor Applications in Construction and LandscapingWartaJul.18,2025

-

Butterfly Valve Types StandardsWartaJul.18,2025

Produk patali