Feb . 19, 2025 01:18 Back to list

adjusting a micrometer

Precision in engineering and craftsmanship often hinges on the accuracy of measurements. One of the most critical tools for ensuring such precision is the micrometer. Properly adjusting a micrometer is essential to achieving measurements that are both accurate and reliable, a skill that underscores expertise and authority in the field of precision measurement.

Expert machinists often recommend checking the zero position at regular intervals, especially if the micrometer has been subjected to temperature changes or physical shocks, as these can affect its accuracy. Maintaining a consistent room temperature is one of the most authoritative practices to keep measurements true. Metals expand and contract with temperature fluctuations, and precision tools are no exception. When adjusting for different tasks, such as measuring different materials or following specific standards, the use of gauge blocks (or slip gauges) is often advised. These tools provide a known standard dimension to which the micrometer can be calibrated. Expert use of gauge blocks involves not only careful placement but also awareness of temperature differences between the blocks and the micrometer itself. Proper use ensures that the micrometer reads as close to absolute true values as possible. For practices involving trust and reliability, always test the micrometer multiple times with the same known measurement. Consistency across repeated measurements reinforces the tool's accuracy and builds confidence in the results. Moreover, it’s essential to handle the micrometer with care. Store it in a protective case when not in use to prevent dust accumulation and physical damage. Regular professional calibration, beyond what can be adjusted in-house, is also recommended, significantly for frequently used tools in high-stakes environments. The importance of adjusting a micrometer correctly cannot be overstated. It is a testament to a machinist's expertise, a reflection of precision and attention to detail. Mastery of this adjustment process elevates not just the quality of work but reinforces the trust and authority placed in those skilled enough to wield such precision instruments effectively.

Expert machinists often recommend checking the zero position at regular intervals, especially if the micrometer has been subjected to temperature changes or physical shocks, as these can affect its accuracy. Maintaining a consistent room temperature is one of the most authoritative practices to keep measurements true. Metals expand and contract with temperature fluctuations, and precision tools are no exception. When adjusting for different tasks, such as measuring different materials or following specific standards, the use of gauge blocks (or slip gauges) is often advised. These tools provide a known standard dimension to which the micrometer can be calibrated. Expert use of gauge blocks involves not only careful placement but also awareness of temperature differences between the blocks and the micrometer itself. Proper use ensures that the micrometer reads as close to absolute true values as possible. For practices involving trust and reliability, always test the micrometer multiple times with the same known measurement. Consistency across repeated measurements reinforces the tool's accuracy and builds confidence in the results. Moreover, it’s essential to handle the micrometer with care. Store it in a protective case when not in use to prevent dust accumulation and physical damage. Regular professional calibration, beyond what can be adjusted in-house, is also recommended, significantly for frequently used tools in high-stakes environments. The importance of adjusting a micrometer correctly cannot be overstated. It is a testament to a machinist's expertise, a reflection of precision and attention to detail. Mastery of this adjustment process elevates not just the quality of work but reinforces the trust and authority placed in those skilled enough to wield such precision instruments effectively.

Next:

Latest news

-

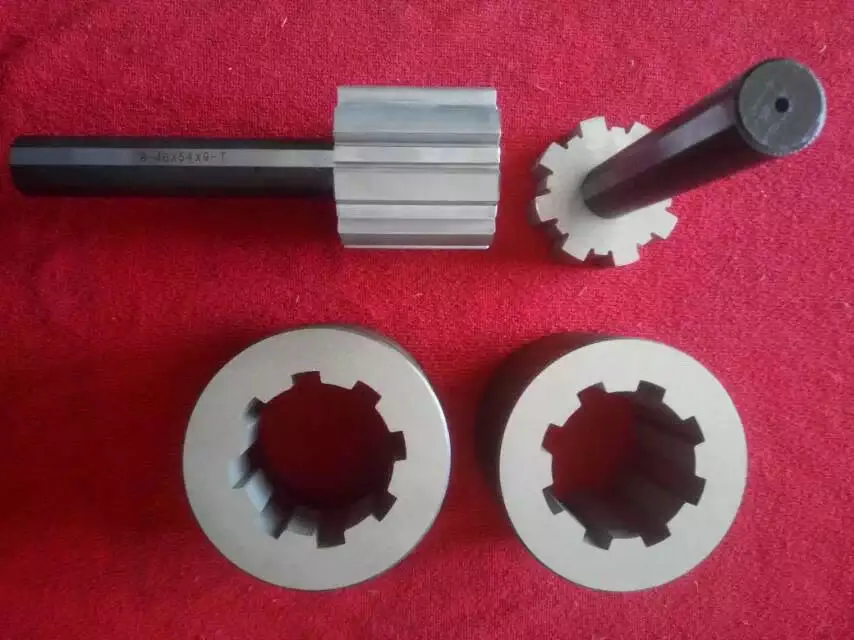

Precision Manufacturing with Advanced Spline Gauge DesignNewsJul.31,2025

-

Industrial-Grade Calibrated Pin Gauges for Exact MeasurementsNewsJul.31,2025

-

Industrial Filtration Systems Depend on Quality Filter DN50 SolutionsNewsJul.31,2025

-

High-Performance Gate Valve WholesaleNewsJul.31,2025

-

Granite Surface Plate The Ultimate Solution for Precision MeasurementNewsJul.31,2025

-

Granite Industrial Tools The Ultimate Guide for Bulk BuyersNewsJul.31,2025

Related PRODUCTS