Jul . 29, 2025 10:02 Khutlela lethathamong

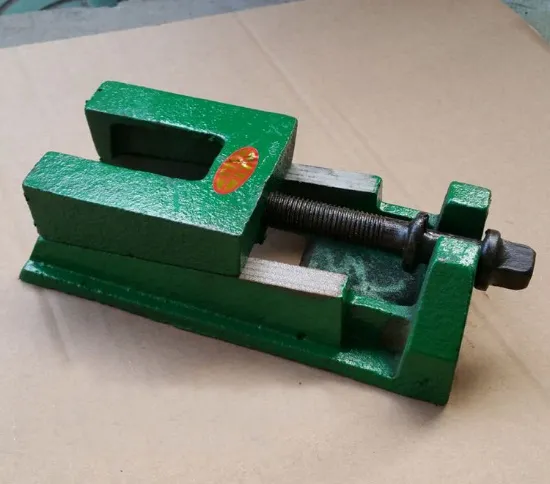

Pad Iron Reinforces Anchor Points

In the world of industrial machinery, precision, stability, and longevity are paramount. Whether in manufacturing plants, workshops, or heavy industrial settings, the performance of machinery directly impacts productivity, safety, and operational costs. Three critical components that play a vital role in maintaining these standards are the pad iron, machine vibration pads, and the phenomenon of pad vibration. A pad iron ensures precise leveling, machine vibration pads mitigate the effects of operational vibrations, and understanding pad vibration helps prevent inefficiencies and damage. This article delves into their functions, benefits, applications, installation practices, and common questions, providing a comprehensive guide for professionals seeking to optimize machinery performance through these essential tools.

The Role of a Pad Iron in Achieving Precision Leveling for Machinery

A pad iron is a foundational tool in machinery setup, designed to bridge gaps between machinery bases and uneven surfaces, ensuring precise leveling. Its primary role is to distribute the weight of the machinery evenly across the surface, preventing tilting, shifting, or uneven stress that can compromise performance. Unlike makeshift shims or spacers, a pad iron is engineered for durability and accuracy, typically crafted from high-strength materials that resist deformation under heavy loads.

The importance of a pad iron lies in its ability to correct minor surface irregularities. In industrial settings, floors or foundations rarely have perfect flatness, especially after years of use or in new construction where settling occurs. A pad iron fills these gaps, creating a stable base that ensures machinery operates as intended. For example, in CNC machines, lathes, or precision measuring equipment, even a slight tilt can lead to inaccurate outputs, wasted materials, or increased wear on moving parts. By using a pad iron to level the machinery, operators maintain the precision required for high-quality production.

Additionally, a pad iron helps extend machinery lifespan by reducing uneven stress on components. When machinery is properly leveled, bearings, shafts, and other moving parts experience uniform wear, minimizing the risk of premature failure and costly repairs. This makes the pad iron an essential investment for any operation where machinery reliability is critical.

How Machine Vibration Pads Mitigate Operational Noise and Wear

Machine vibration pads are specialized components designed to absorb and dampen vibrations generated by operating machinery, offering a range of benefits that enhance workplace conditions and equipment longevity:

- Vibration Absorption: The core function of machine vibration padsis to absorb kinetic energy from vibrations, preventing it from transferring to the floor, adjacent machinery, or the surrounding environment. This reduces the risk of resonance, which can amplify vibrations and cause damage to structures or equipment.

- Noise Reduction: Vibrations often translate to operational noise, which can be disruptive to workers and violate safety regulations. Machine vibration padsdampen these vibrations, lowering noise levels and creating a quieter, more comfortable workspace.

- Wear Reduction: By minimizing vibration, machine vibration padsreduce stress on machinery components such as bolts, gears, and motors. This lowers the rate of wear and tear, extending the intervals between maintenance and repairs.

- Floor Protection: Constant vibrations can damage concrete floors, leading to cracks, uneven surfaces, or structural weakening over time. Machine vibration padsact as a buffer, protecting floors from the impact of repeated vibrations.

- Stability Enhancement: Even well-leveled machinery can shift slightly due to vibrations. Machine vibration padsprovide additional grip, preventing movement and ensuring the machinery remains securely positioned during operation.

These benefits make machine vibration pads indispensable in industries such as manufacturing, automotive, aerospace, and power generation, where machinery runs continuously and vibration control is essential.

Key Industries Benefiting from Pad Iron, Machine Vibration Pads, and Anti-Vibration Solutions

Pad iron, machine vibration pads, and related anti-vibration solutions are utilized across a wide range of industries, each leveraging these tools to address unique operational challenges:

- Manufacturing: In factories producing automotive parts, electronics, or consumer goods, precision is critical. A pad ironensures machinery like CNC mills and assembly lines are level, while machine vibration pads reduce vibrations that could affect product quality or damage sensitive equipment.

- Aerospace and Defense: High-precision machinery used in aircraft component manufacturing or weapons production relies on pad ironfor exact leveling. Machine vibration pads protect delicate measuring tools from vibrations that could compromise accuracy in critical tolerances.

- Power Generation: Power plants, whether coal, gas, or renewable, house large turbines and generators that generate significant vibrations. Machine vibration padsreduce noise and wear, while pad iron levels heavy equipment to prevent structural stress.

- Medical Device Manufacturing: Medical equipment such as MRI machines, laser systems, and diagnostic tools require stable, vibration-free operation. Machine vibration padsminimize interference from external vibrations, and pad iron ensures precise alignment for accurate results.

- Food and Beverage Processing: Machinery used in packaging, bottling, or food production must adhere to strict hygiene standards. Non-marking, chemical-resistant machine vibration padsprotect floors and reduce noise, while pad iron levels equipment to prevent spills and ensure smooth operation.

In each industry, these tools contribute to safer, more efficient, and higher-quality operations.

Proper Installation Techniques for Pad Iron and Machine Vibration Pads to Maximize Efficiency

Correct installation is critical to ensuring that pad iron and machine vibration pads perform as intended. The following table outlines key installation steps for each, highlighting best practices to maximize efficiency:

|

Step |

Pad Iron Installation |

Machine Vibration Pad Installation |

|

1. Site Preparation |

Clean the floor surface, removing debris, oil, or uneven patches that could affect leveling. |

Ensure the floor is clean and dry; repair cracks or uneven areas to create a stable base. |

|

2. Positioning |

Place the pad iron at pre-marked points under the machinery’s base, aligning with load-bearing areas. |

Select machine vibration pads sized to match the machinery’s weight and footprint; position them at each support point. |

|

3. Leveling |

Use a precision level to check alignment; adjust the pad iron by adding or removing shims (if needed) to achieve perfect horizontal positioning. |

Press the pads firmly into place, ensuring full contact with both the machinery base and the floor to avoid gaps. |

|

4. Securing |

Fasten the machinery to the pad iron using appropriate bolts; torque bolts to manufacturer specifications to prevent loosening. |

For heavy machinery, secure the machine vibration pads to the floor with adhesives or fasteners (if recommended) to prevent shifting. |

|

5. Testing |

Run the machinery briefly and recheck leveling; make adjustments if vibrations or movement are detected. |

Operate the machinery at normal load and check for reduced vibration and noise; reposition pads if hotspots or uneven wear occur. |

Following these steps ensures that both pad iron and machine vibration pads function optimally, providing long-term stability and vibration control.

FAQS about Pad Iron, Machine Vibration Pads, and Pad Vibration

How does a Pad Iron contribute to machinery stability?

A Pad Iron contributes to machinery stability by creating a level, uniform base between the machinery and the floor. It fills gaps caused by uneven surfaces, distributing the machinery’s weight evenly to prevent tilting or shifting during operation. This even weight distribution reduces stress on components, minimizes vibration, and ensures that moving parts operate in alignment, enhancing both precision and longevity. Without a Pad Iron, uneven loading can lead to premature wear, inaccurate outputs, and safety risks.

What materials are used in Machine Vibration Pads to reduce vibration?

Machine Vibration Pads are typically made from elastic or resilient materials designed to absorb and dampen vibrations. Common materials include natural rubber, synthetic rubber (such as neoprene), polyurethane, and cork-rubber composites. These materials offer high elasticity, allowing them to compress under load and return to shape, absorbing kinetic energy in the process. Many machine vibration pads also feature reinforced layers or embedded metal plates to enhance strength without sacrificing vibration-damping properties, making them suitable for heavy machinery.

What factors contribute to Pad Vibration in industrial machinery setups?

Pad Vibration in industrial setups is often caused by poor installation, such as misaligned pad iron or machine vibration pads placed on uneven surfaces, which create gaps allowing movement. Inadequate sizing—using pads too small for the machinery’s weight—can also lead to overloading and vibration. Material degradation, such as hardened or cracked machine vibration pads, reduces their ability to absorb energy, increasing pad vibration. Additionally, loose fasteners connecting the machinery to the pad or the pad to the floor can amplify movement during operation.

Can a Pad Iron be used alongside Machine Vibration Pads for enhanced performance?

Yes, a Pad Iron can be used alongside Machine Vibration Pads to enhance performance, creating a combined solution for leveling and vibration control. The pad iron first ensures precise leveling of the machinery, correcting surface irregularities that could compromise stability. The machine vibration pads, placed either under the pad iron or directly under the machinery, then absorb vibrations generated during operation. This combination is particularly effective for heavy, precision machinery that requires both perfect alignment and vibration damping to maintain accuracy and reduce wear.

How do I maintain Machine Vibration Pads to prevent excessive Pad Vibration?

To maintain Machine Vibration Pads and prevent excessive pad vibration, regularly inspect them for signs of wear, such as cracks, hardening, or deformation. Clean the pads periodically to remove oil, dirt, or chemicals that can degrade material elasticity. Ensure the pads remain properly positioned—reposition or replace them if they shift or develop gaps. Avoid overloading the pads by adhering to weight limits, and replace them entirely when they show significant degradation (typically every 3–5 years, depending on usage). These steps preserve the pads’ ability to dampen vibrations effectively.

At [Storaen (Cangzhou) International Trading Co], we are dedicated to providing high-quality pad iron, machine vibration pads, and anti-vibration solutions tailored to your industrial needs. Our products are engineered with precision, using durable materials to ensure reliable performance in even the most demanding environments. We invite you to visit our website to explore our range of pad iron designs, test the quality of our machine vibration pads, and consult with our experts about preventing pad vibration in your specific setup. Our team will guide you through product selection, installation tips, and maintenance best practices to help you achieve optimal machinery stability and efficiency. Don’t let poor leveling or uncontrolled vibration hinder your operations—contact us today to schedule your visit and take the first step toward enhanced performance and longevity for your equipment.

-

Thread Plug Gauge Requires Careful HandlingLitabaJul.29,2025

-

Surface plate calibrationLitabaJul.29,2025

-

Ring Gauge Ensures Machining AccuracyLitabaJul.29,2025

-

Pad Iron Reinforces Anchor PointsLitabaJul.29,2025

-

Ground anchor stabilizes embankmentsLitabaJul.29,2025

-

Granite Box Maintains Precision FlatnessLitabaJul.29,2025

Tse amanang le PRODUCTS