Jul . 03, 2025 09:07 Khutlela lethathamong

Benefits of Using Granite Surface Plates in Machining

In the machining industry, precision and reliability are the cornerstones of high - quality production. Storaen (Cangzhou) International Trading Co. recognizes the value of granite surface plates in achieving these standards.

Granite Surface Plate Specifications Table

|

Parameter |

Lintlha |

|

Lintho tse bonahalang |

Granite |

|

Tlhaloso |

1000X750mm - 3000X4000mm or customize |

|

Surface Options |

flat, tapped holes, T - slots, etc. |

|

Working Surface Hardness |

HS70 |

|

Surface Treatment |

ground finish |

|

Kereiti ya Precision |

0 - 2 |

|

Sephutheloana |

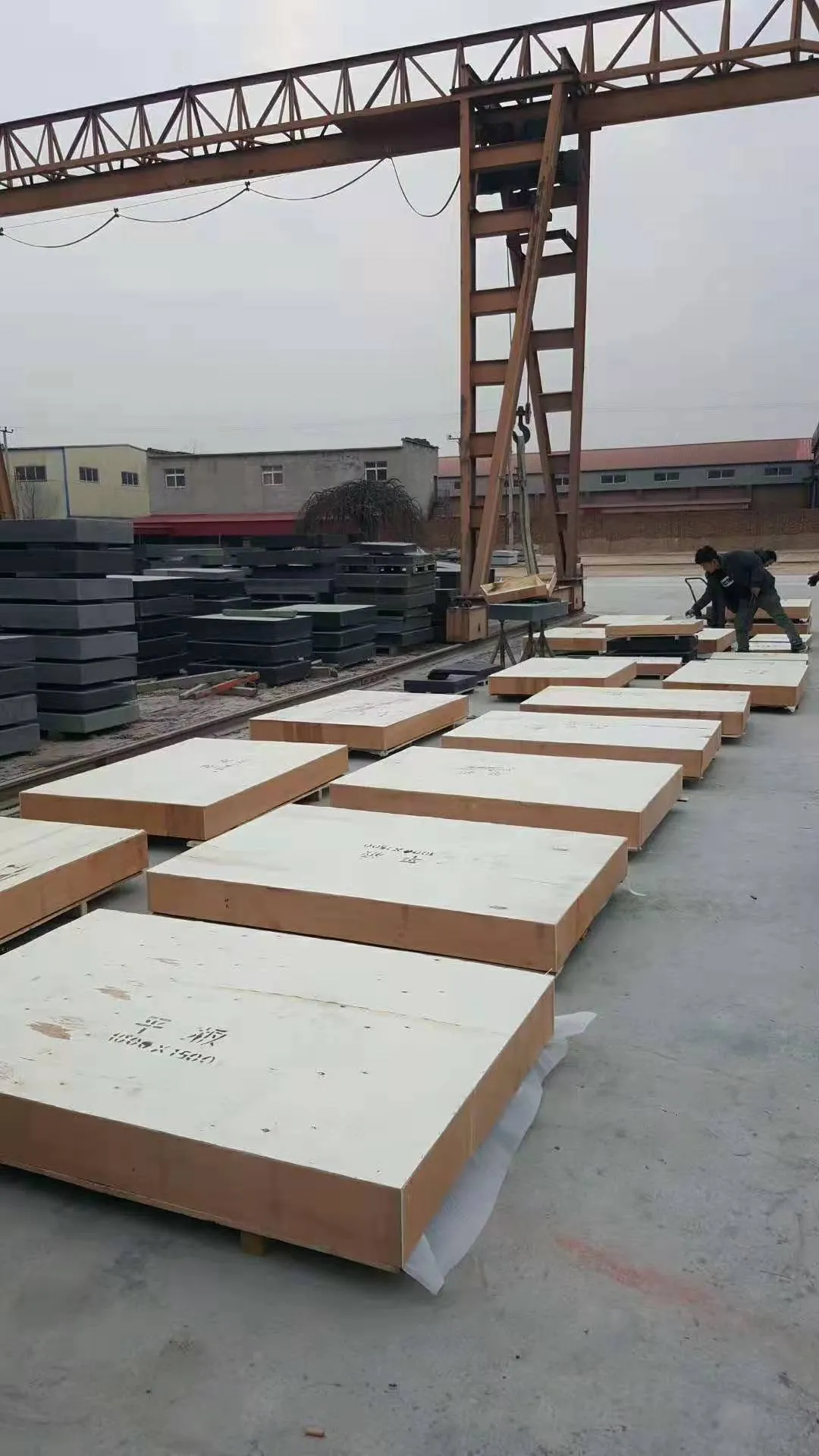

lebokose la plywood |

Understanding the Granite Surface Plate

- A granite surface plate is a fundamental tool in machining, renowned for its rust - less properties. Storaen (Cangzhou) International Trading Co. offers these plates, which are harder than cast iron surface plates. They serve as a stable and accurate platform for precision gauging, inspection, layout, and marking. Laboratories, engineering industries, and workshops prefer them for their ability to maintain precision over time.

- The composition of granite gives the granite surface plateunique characteristics. Its hardness (HS70 on the working surface) ensures resistance to wear and tear, even in high - volume machining environments. The ground finish provides a smooth and flat surface, which is crucial for accurate measurements and inspections.

- As a fabrication table, the granite surface plateoffers a reliable base for various machining operations. Whether it's assembling precision components or conducting quality checks, the plate's stability minimizes errors caused by uneven surfaces.

Advantages of Granite Reference Plate in Machining

- Accuracy and Consistency: A granite reference plateprovides a high - precision reference for machining tasks. Its flatness and stability ensure that measurements and inspections are consistent, reducing the likelihood of errors in the machining process. Storaen (Cangzhou) International Trading Co. ensures that their granite reference plates meet strict precision grades (0 - 2), making them suitable for even the most demanding applications.

- Durability: Granite's inherent hardness makes the granite reference platehighly durable. It can withstand the rigors of daily machining use, including contact with heavy tools and workpieces, without significant wear. This durability translates to a longer service life, providing cost - effectiveness for machining facilities in the long run.

- Resistance to Environmental Factors: Unlike some other materials, granite is resistant to rust, corrosion, and environmental changes. A granite reference platemaintains its properties in various conditions, ensuring that machining operations are not affected by humidity, temperature fluctuations, or exposure to chemicals.

Long - Term Cost - Effectiveness of Granite Surface Plates

- Reduced Maintenance Costs: Due to their durability and resistance to wear, granite surface platesrequire minimal maintenance. Unlike other materials that may need frequent repairs or replacements, granite plates can maintain their accuracy and performance over a long period. This reduces the overall maintenance costs for machining facilities.

- Enhanced Productivity: The accuracy and stability of granite surface platescontribute to enhanced productivity in machining. By reducing errors and rework, machining operations can be completed more efficiently. This leads to increased output and improved profitability for machining businesses. Storaen (Cangzhou) International Trading Co. emphasizes these long - term cost - effectiveness benefits to wholesalers and their clients.

- Investment Value: A granite surface plateis a valuable investment for machining facilities. Its long service life and ability to maintain precision make it a cost - effective choice in the long run. Wholesalers can highlight this investment value to clients, showcasing how granite surface plates can contribute to the success of their machining operations.

Granite Surface Plate FAQS

What makes a granite reference plate suitable for high - precision machining?

A granite reference plate is suitable for high - precision machining due to its inherent properties. Its high hardness (HS70) ensures minimal wear, and the ground finish provides excellent flatness. Storaen (Cangzhou) International Trading Co. supplies granite reference plates with precision grades (0 - 2), ensuring that they can meet the strict accuracy requirements of high - precision machining operations.

Can a fabrication table made of a granite surface plate be customized?

Yes, a fabrication table in the form of a granite surface plate can be customized. Storaen (Cangzhou) International Trading Co. offers customization options such as different sizes (1000X750mm - 3000X4000mm or customize), surface features like tapped holes and T - slots, to meet the specific needs of machining facilities.

How does a granite surface plate compare to cast iron surface plates in machining?

A granite surface plate has several advantages over cast iron surface plates in machining. It is more resistant to rust, has higher hardness (HS70 compared to cast iron), and offers better stability in various environmental conditions. These properties make granite surface plates a preferred choice for precision machining applications.

What is the precision grade of the granite surface plates offered by Storaen (Cangzhou) International Trading Co.?

The granite surface plates offered by Storaen (Cangzhou) International Trading Co. have a precision grade of 0 - 2. This ensures a high level of accuracy, making them suitable for a wide range of machining tasks that require precise measurements and inspections.

How should a granite surface plate be maintained for optimal performance in machining?

To maintain a granite surface plate for optimal performance in machining, regular cleaning is essential. Use a soft cloth and a mild cleaning solution to remove dirt and debris. Avoid using abrasive materials that could scratch the surface. Additionally, periodic calibration checks can help ensure that the plate maintains its accuracy over time. Storaen (Cangzhou) International Trading Co. can provide guidance on proper maintenance procedures for their granite surface plates.

-

Welding Methods Used in Metal Table FabricationLitabaJul.03,2025

-

Sustainable Materials in Silence Check Valve ManufacturingLitabaJul.03,2025

-

Installation Guide for Cast Iron Y StrainersLitabaJul.03,2025

-

How to Carve a Block of GraniteLitabaJul.03,2025

-

Creating Customized Measurement PlatformsLitabaJul.03,2025

-

Benefits of Using Granite Surface Plates in MachiningLitabaJul.03,2025

Tse amanang le PRODUCTS