Jun . 11, 2025 14:27 Ku laabo liiska

Welding Workbench vs. Standard Workbench: Key Differences

When it comes to workshop equipment, the choice between a welding workbench and a standard workbench can significantly impact your productivity, safety, and project outcomes. While both serve as foundational surfaces for various tasks, they are designed with distinct purposes in mind. In this article, we'll explore the key differences between these two workbenches, with a focus on how features like material composition, structural design, and affordability set them apart—especially when considering options like a welding table cast iron or an affordable welding table.

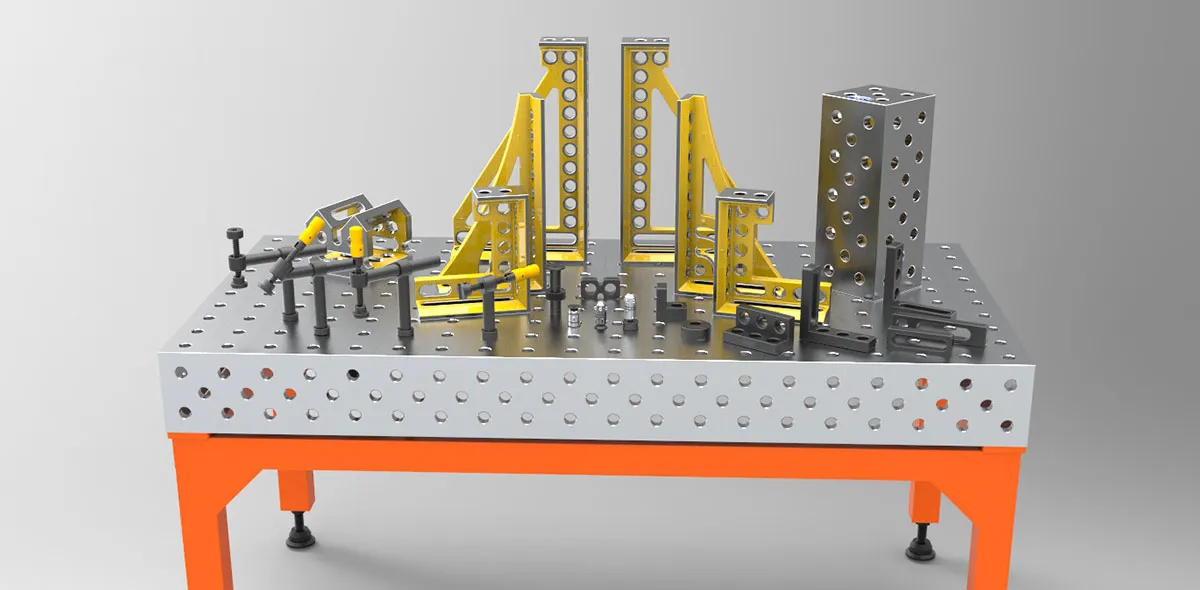

Design and Structure: The Foundation of a Durable Welding Workbench

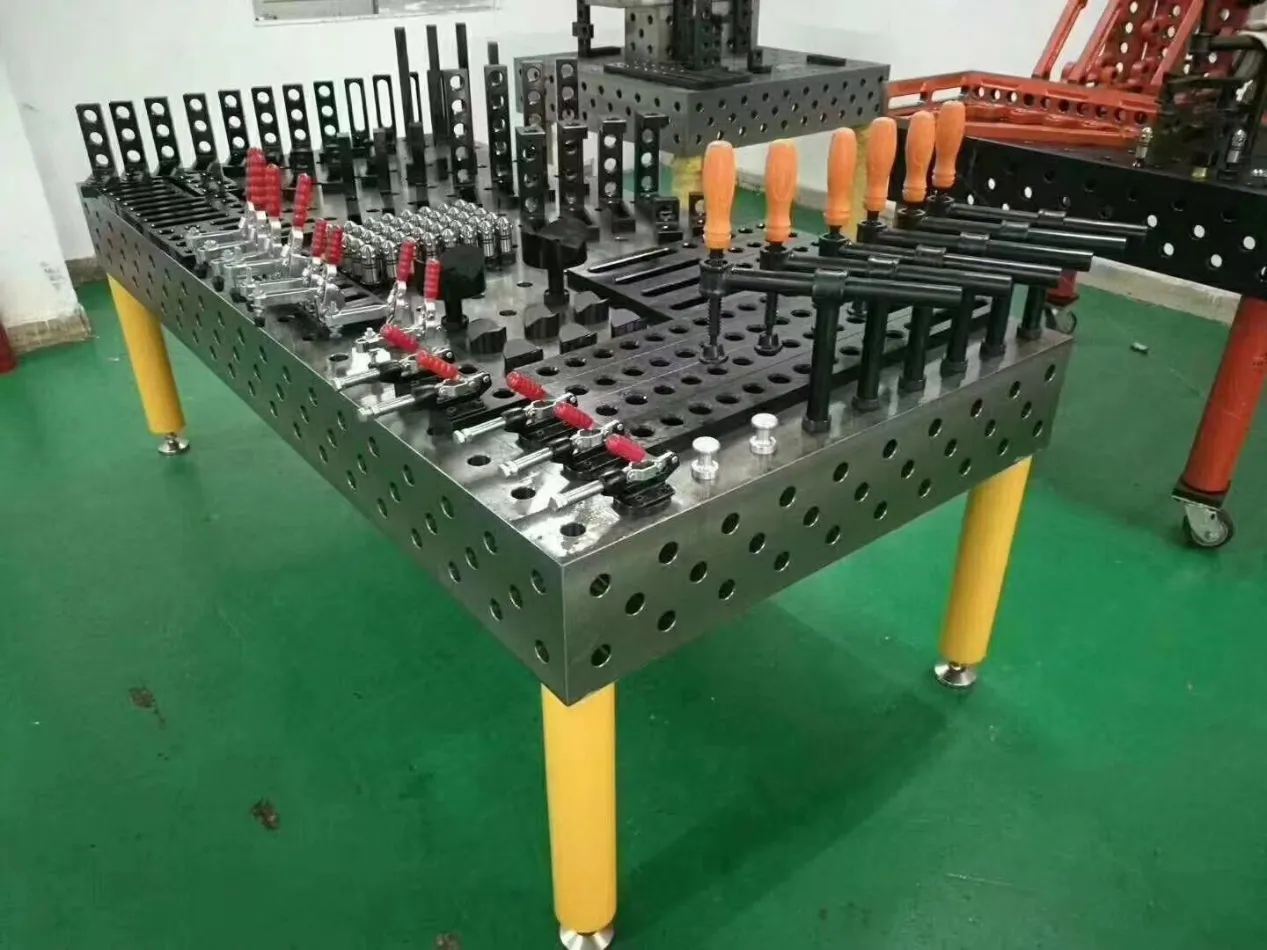

A welding workbench is engineered to withstand the harsh conditions of welding tasks, where high temperatures, sparks, and heavy-duty impacts are common. Unlike standard workbenches, which often have lightweight frames and basic leg structures, welding workbenches feature robust, reinforced frames—typically constructed from heavy-gauge steel or welding table cast iron—to ensure stability and resistance to warping or bending under extreme heat. Many welding workbenches also include built-in features like grounding points to dissipate static electricity, fire-resistant surfaces, and integrated clamping systems to secure workpieces during welding.

Standard workbenches, on the other hand, are designed for general-purpose tasks such as assembly, crafting, or light machining. They usually have simpler designs with wooden or laminate surfaces and lighter metal or wooden legs. While they offer basic stability for everyday tasks, they lack the specialized features needed to handle the rigors of welding, such as heat resistance or anti-static properties. This makes them unsuitable for welding projects, where safety and durability are paramount.

Material Composition: Why Welding Table Cast Iron Stands Out

The materials used in constructing a workbench play a crucial role in its performance, especially for welding applications. Welding table cast iron is a popular choice for welding workbenches due to its exceptional durability and thermal properties. Cast iron has a high melting point, allowing it to withstand the intense heat generated during welding without deforming. It also has excellent vibration-dampening capabilities, which helps reduce noise and stabilize workpieces, leading to more precise welds. Additionally, cast iron surfaces are often ground to a smooth finish, providing a flat, accurate base for measuring and aligning materials—an essential feature for metalworking projects.

Standard workbenches, in contrast, frequently use materials like particleboard, MDF, or softwoods for their surfaces. These materials are prone to damage from heat, sparks, and moisture, making them ill-suited for welding. Even if a standard workbench has a metal frame, the surface material alone can compromise its functionality in a welding environment. Investing in a welding table cast iron or a steel-reinforced welding workbench ensures that your equipment can keep up with the demands of heavy-duty welding tasks.

Functionality and Cost: Balancing Performance with an Affordable Welding Table

While welding workbenches are designed for specialized tasks, they also come in a range of price points to suit different budgets—including options for an affordable welding table. Many manufacturers offer welding workbenches that combine durability with cost-effectiveness, using materials like mild steel or composite cast iron to keep prices reasonable without sacrificing quality. These affordable models still feature key welding-specific features, such as reinforced legs, heat-resistant surfaces, and pre-drilled holes for clamping, making them ideal for hobbyists, DIY enthusiasts, or small workshops.

Standard workbenches may seem cheaper upfront, but their lack of specialized features can lead to long-term costs. For example, a damaged standard workbench surface from welding sparks will need frequent repairs or replacements, ultimately costing more than investing in a purpose-built affordable welding table from the start. Moreover, welding on an unsuitable workbench can compromise the quality of your welds and pose safety risks, such as fire hazards or unstable work surfaces.

When evaluating cost, it's important to consider the total cost of ownership. A well-built welding workbench, even an affordable one, will offer years of reliable service, making it a smarter investment for anyone who regularly works with welding equipment.

FAQs About Welding Workbenches and Affordable Welding Tables

What are the main advantages of choosing a welding workbench over a standard workbench?

A welding workbench offers superior heat resistance, structural stability, and specialized features like grounding points and clamping systems, making it safer and more efficient for welding tasks. Unlike standard workbenches, it's designed to handle high temperatures, sparks, and heavy loads, ensuring better performance and longevity in a welding environment.

Why is a welding table cast iron a preferred material for welding workbenches?

Welding table cast iron is valued for its high melting point, resistance to warping, and vibration-dampening properties. It provides a flat, stable surface that can withstand the intense heat of welding while reducing noise and improving precision—essential for creating accurate, high-quality welds.

Can I find an affordable welding table that doesn't compromise on quality?

Yes! Our company offer affordable welding tables that balance cost with durability. Look for models with steel or cast iron frames, heat-resistant surfaces, and essential welding features like clamping slots. These options are perfect for those who want a reliable workbench without overspending.

How much weight can a typical welding workbench support compared to a standard workbench?

Welding workbenches are built to handle heavy loads, often supporting 500 pounds or more, thanks to their reinforced frames and solid materials like welding table cast iron. Standard workbenches, by comparison, usually support 200–300 pounds at most, making them unsuitable for heavy welding projects involving large or bulky materials.

Are there welding workbenches suitable for small workshops or home use?

Absolutely! Many affordable welding tables are designed for compact spaces, offering all the essential features of a professional-grade workbench in a smaller footprint. Whether you're a hobbyist or a small business owner, you can find a welding workbench that fits your space and budget while delivering the performance you need.

Choosing the right workbench for your welding projects is about more than just price—it's about matching your equipment to the demands of your tasks. A welding workbench, whether made from welding table cast iron or designed as an affordable welding table, offers the durability, safety, and functionality that standard workbenches simply can't match. By investing in a purpose-built welding workbench, you'll enhance your productivity, improve the quality of your work, and ensure a safer working environment for years to come.

-

Thread Plug Gauge Requires Careful HandlingWararkaJul.29,2025

-

Surface plate calibrationWararkaJul.29,2025

-

Ring Gauge Ensures Machining AccuracyWararkaJul.29,2025

-

Pad Iron Reinforces Anchor PointsWararkaJul.29,2025

-

Ground anchor stabilizes embankmentsWararkaJul.29,2025

-

Granite Box Maintains Precision FlatnessWararkaJul.29,2025

Alaabooyinka La Xiriira