Jun . 06, 2025 10:51 Ku laabo liiska

Essential Granite Measuring Tools for Precision Work

In the demanding landscape of precision measurement and industrial craftsmanship, the right tools are the backbone of accuracy and reliability. Whether you’re engaged in high - stakes manufacturing, intricate research, or quality control processes, the choice of measuring tools directly impacts the integrity of your work. Granite measuring tools, with their unique combination of natural stability, durability, and precision, have emerged as indispensable assets in countless industries. Their ability to deliver consistent, interference - free measurements across diverse environments makes them a cornerstone for any operation where precision is non - negotiable.

Unmatched Precision with Granite Measuring Tool

In the world of precision work, granite measuring tools stand out as paragons of accuracy. The inherent qualities of granite, such as its low coefficient of thermal expansion, ensure that these tools maintain their shape and measurement integrity across a wide range of environmental conditions. Whether it’s in a high - tech manufacturing facility or a research laboratory, granite measuring tools provide a stable and reliable platform for the most exacting measurements. Their non - magnetic and non - conductive nature further makes them suitable for applications where interference could skew results. This precision is not just a feature; it’s a guarantee that gives industries the confidence to undertake complex projects with the assurance of accurate outcomes.

Prime Picks in Granite Tools for Sale

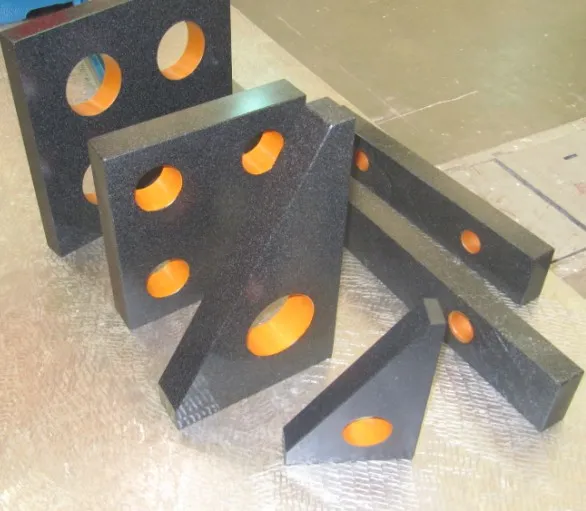

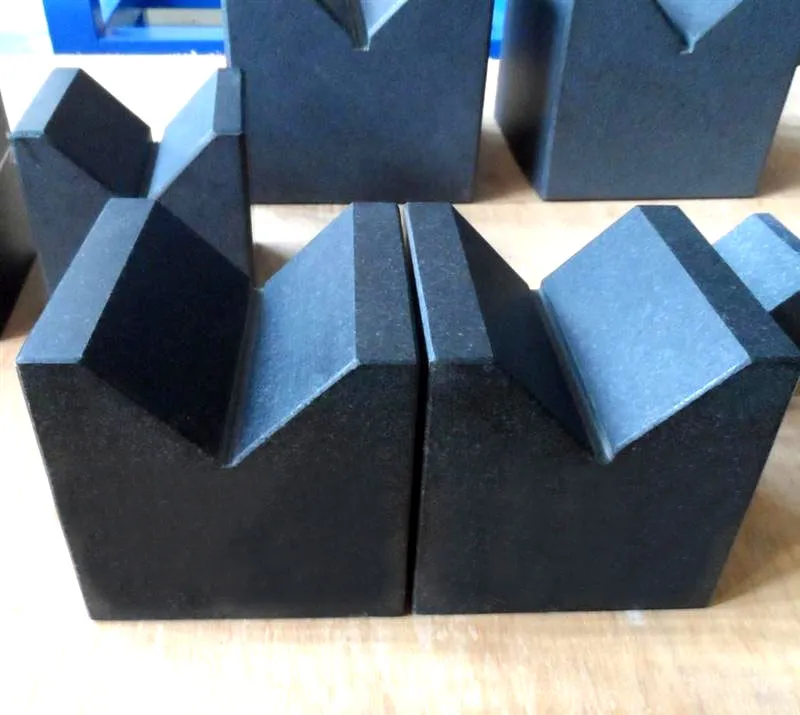

When it comes to granite tools for sale, we offer a curated selection that meets the diverse needs of various sectors. Each granite measuring tool in our inventory undergoes rigorous quality checks to ensure it adheres to the highest standards. From basic surface plates that serve as the foundation for countless measurement tasks to more specialized angle plates and V - blocks, our range is designed to cater to both novice users and seasoned professionals. What sets our granite tools for sale apart is not just the quality but also the attention to detail in design and functionality. We understand that in the market for precision tools, every feature counts, and our products are crafted to deliver performance that exceeds expectations.

Powering Industries with Granite Industrial Tools

Granite industrial tools are the unsung heroes behind the scenes of many industrial operations. In metalworking, they provide a stable base for inspecting the flatness of components, ensuring that parts fit together seamlessly. In the automotive industry, granite measuring tools play a crucial role in the assembly line, helping to maintain the precision required for engine components and other vital parts. Their durability and resistance to wear make them ideal for the demanding conditions of industrial environments. By incorporating granite industrial tools into their processes, businesses can enhance productivity, reduce errors, and ultimately improve the quality of their end products.

The Future of Granite Industrial Tools

As technology continues to evolve, so do granite industrial tools. We are at the forefront of innovation, constantly exploring new ways to enhance the capabilities of our granite measuring tools. From integrating advanced digital interfaces for easier data collection to developing new manufacturing techniques for even higher precision, we are committed to staying ahead of the curve. The future of granite industrial tools lies in their ability to adapt to the changing needs of industries, and we are dedicated to providing products that are not only relevant today but also ready for the challenges of tomorrow.

FAQS about Granite Measuring Tool

How do granite measuring tools benefit different industries?

Granite measuring tools offer unparalleled benefits across industries. In the aerospace industry, their high precision and stability are crucial for manufacturing components that require minute tolerances, ensuring the safety and efficiency of aircraft. In the electronics sector, their non - magnetic and non - conductive properties prevent interference with sensitive electronic components during measurement. In general manufacturing, granite industrial tools like surface plates provide a reliable reference surface for quality control, reducing errors and improving the overall quality of products. This versatility makes granite measuring tools an essential asset for a wide range of industrial applications.

What makes your granite tools for sale superior?

Our granite tools for sale stand out due to a combination of factors. First, we source only the highest - quality granite, ensuring durability and long - lasting performance. Each tool undergoes a meticulous manufacturing process, with strict quality control measures at every stage. Our focus on design and functionality means that our granite measuring tools and granite industrial tools are not only accurate but also user - friendly. Additionally, our custom - solution offering allows us to meet the unique needs of our customers, providing a level of service and product quality that is hard to match.

Can granite industrial tools withstand harsh working conditions?

Yes, granite industrial tools are well - equipped to handle harsh working conditions. Granite is a naturally robust material that is highly resistant to abrasion, corrosion, and temperature fluctuations. This makes granite measuring tools ideal for use in industrial environments where they may be exposed to dust, chemicals, or extreme temperatures. Their solid construction and stable nature ensure that they can maintain their accuracy and functionality even in the most challenging settings, providing a reliable solution for industrial measurement needs.

How can I choose the right granite tools for sale?

When choosing granite tools for sale, consider your specific measurement requirements. Determine the type of work you’ll be doing and the level of precision needed. For basic flatness measurements, a granite surface plate may suffice, while more complex tasks may require specialized granite industrial tools like angle plates or V - blocks. Also, think about the size and weight of the tool, as it needs to fit comfortably into your workspace. If you have unique requirements, don’t hesitate to explore our custom - solution options. Our team is always available to guide you through the selection process and help you find the perfect granite measuring tool for your needs.

What does the future hold for granite industrial tools?

The future of granite industrial tools is filled with exciting possibilities. As industries demand even higher levels of precision and efficiency, granite measuring tools will continue to evolve. We anticipate more integration of digital technology, allowing for real - time data analysis and more seamless communication with other manufacturing systems. Advancements in manufacturing techniques will also lead to tools with even greater accuracy and durability. At the same time, there will be a growing emphasis on sustainability, with efforts to source granite more responsibly and reduce the environmental impact of tool production. Overall, granite industrial tools will remain a vital part of precision work, adapting and innovating to meet the changing needs of industries worldwide.

-

Why the Right Angle Ruler Reigns in MetalworkingWararkaJul.21,2025

-

The Enduring Allure of Granite Boxes in Modern InteriorsWararkaJul.21,2025

-

The Digital Gauging Revolution: Reshaping Thread Rings Inspection's FutureWararkaJul.21,2025

-

How Modern Inspection Platforms Transcend Surface MeasurementWararkaJul.21,2025

-

How Customization Drives Wholesale Success in Parallel RulersWararkaJul.21,2025

-

Fortifying Permanent Steel Ground Anchors Against Corrosion's OnslaughtWararkaJul.21,2025

Alaabooyinka La Xiriira