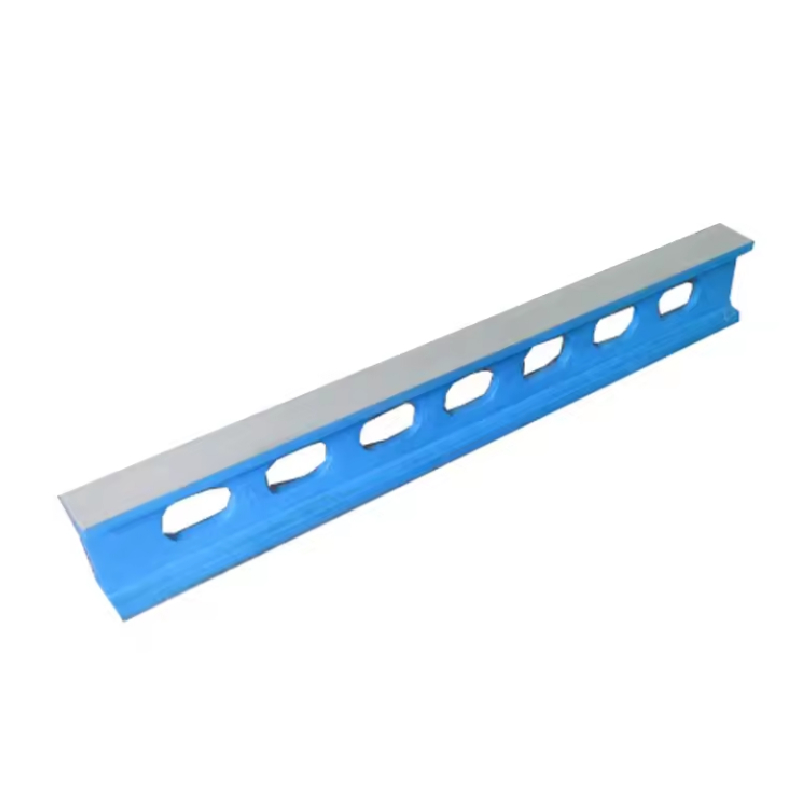

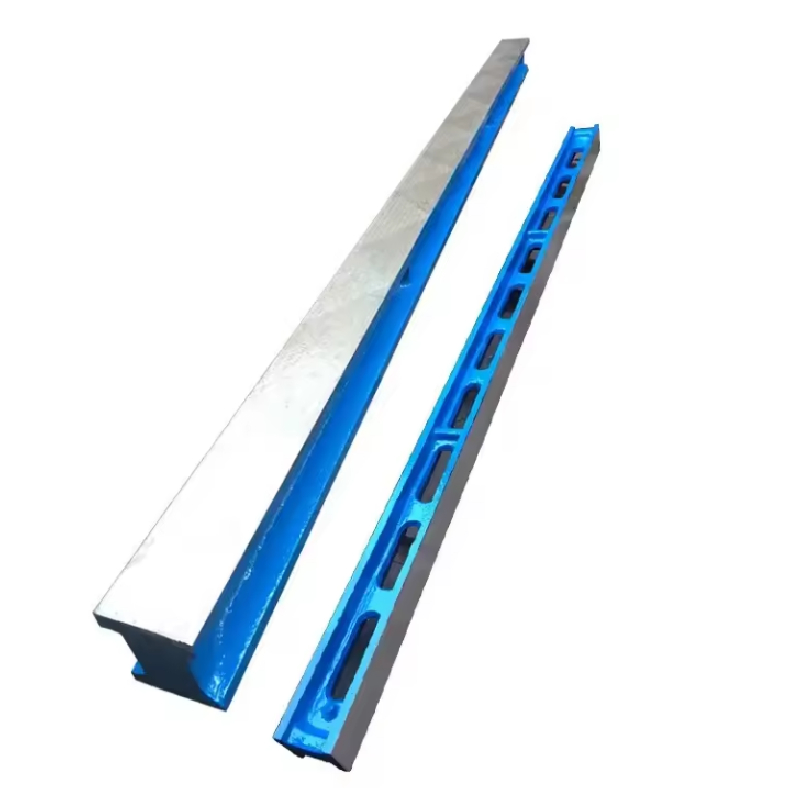

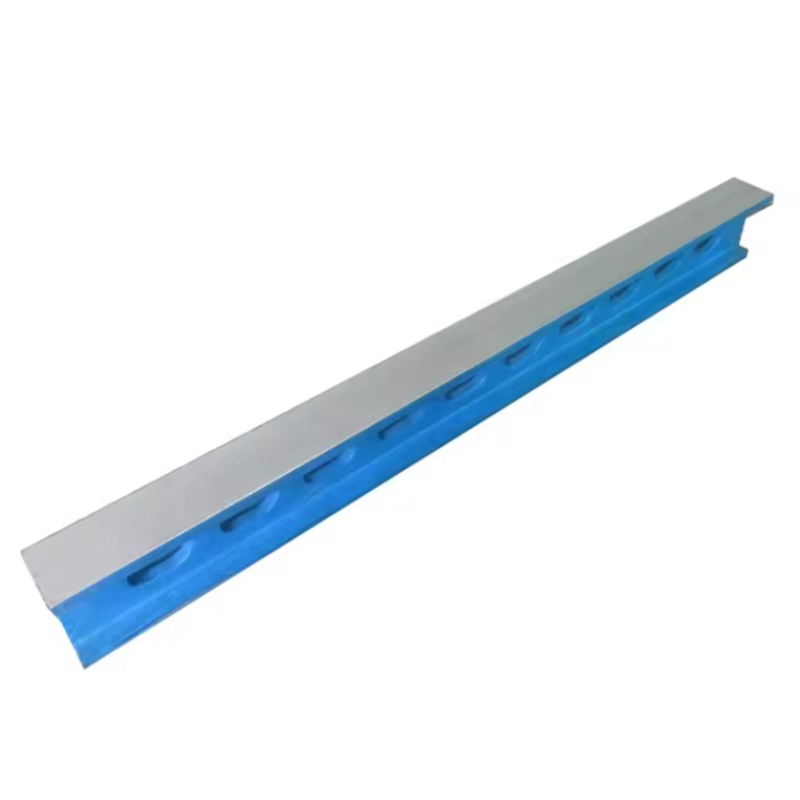

Прямые линейки

Параметр продукта

Место происхождения: Хэбэй, Китай.

Гарантия: 1 год

Индивидуальная поддержка: OEM, ODM, OBM

Фирменное наименование: Сторан

Model Number:2010

Материал: чугун

Точность: по индивидуальному заказу

Режим работы: индивидуальный

Вес изделия: по индивидуальному заказу

Емкость: по индивидуальному заказу

Материал: HT200-300

Спецификация: см. прикрепленную форму или настройте

Обработка поверхности: ручная очистка или чистовое фрезерование.

Foundry process:sand casting

Painting:primer painting

Surface coating:working surface covered with pickling oil

Working temperature:(20±5)℃

Класс точности: 1-3

Custom design:available

Упаковка: фанерный ящик.

Время выполнения

|

Количество (шт.) |

1 - 1 |

> 1 |

|

Срок выполнения (дней) |

30 |

Для переговоров |

Функции

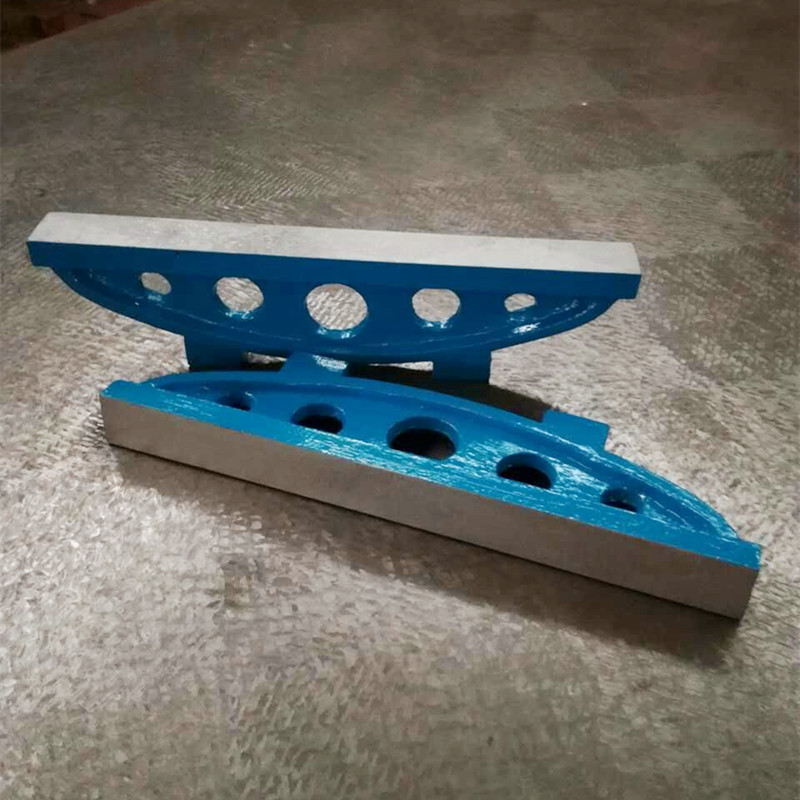

* Ⅰshaped

* Изготовлен из высококачественного чугуна.

* Casting stress – relieved to remove internal stresses.

* Offered in three Grades of accuracies: Grades 0, 1 and 2.

* Normal packaging is plywood box, fine packaging case provided on request at extra cost.

Product Specifications

Материал: ХТ200-300

Specification: see attached form or customize

Surface treatment: hand-scraped or finish-milling

Foundry process: sand casting

Покраска: грунтовка

Surface coating: working surface covered with pickling oil and non-working surface covered with antirust paint

Working temperature: (20±5)℃

Precision grade :1-3

Custom design: available

Packaging: plywood box

Параметр продукта

|

No. |

Width X Length(mm) |

Straightness or Flatness of Working Surface |

Parallelism Between Both Working Surfaces |

||||

|

Precision Degree(μm) |

|||||||

|

1 |

2 |

3 |

1 |

2 |

3 |

||

|

1 |

500 × 45 |

6 |

12 |

|

9 |

18 |

|

|

2 |

750 × 50 |

8 |

15 |

|

12 |

25 |

|

|

3 |

1000 × 55 |

10 |

20 |

|

15 |

30 |

|

|

4 |

1200 × 60 |

12 |

24 |

|

18 |

36 |

|

|

5 |

1500 × 60 |

15 |

30 |

|

20 |

40 |

|

|

6 |

2000 × 80 |

20 |

40 |

80 |

27 |

54 |

|

|

7 |

2500 × 80 |

25 |

50 |

100 |

33 |

65 |

130 |

|

8 |

3000 × 100 |

|

60 |

120 |

|

78 |

156 |

Cast Iron vs. Steel Straight Rulers: Durability & Precision Comparison

Choosing straight rulers for industrial alignment? Material choice defines performance. Storaen compares cast iron and steel metal straightedge tools to show why our cast iron ruler straight edge solutions lead in durability and precision.

1. Strength & Vibration Resistance

Cast Iron (HT200-HT300):

With 180–240HB hardness and 300MPa tensile strength, our cast iron straight edge ruler with handle resists wear 3x better than mild steel. Its microstructure dampens vibrations by 40%, critical for CNC machine alignment or press tool setup where machinery vibrations cause errors.

Steel:

Softer (130–180HB) and prone to scratches (Ra ≥3.2μm), steel straight rulers lose accuracy faster in abrasive environments, lacking cast iron’s robustness.

2. Long-Term Precision Stability

Thermal Consistency:

Cast iron’s low thermal expansion (11.6×10⁻⁶/°C) maintains Class 0 straightness (≤0.001mm/m for 1000mm), stable across 10°C–40°C. Steel expands 25% more, risking ±5μm errors in temperature-sensitive tasks like aerospace component alignment.

Surface Durability:

Stress-relieved and optionally hand-scraped, cast iron metal straightedge retains Ra ≤1.6μm roughness through 10,000 cycles. Steel rulers lose 20% flatness after 5,000 cycles due to micro-deformations.

3. Corrosion Protection & Practical Design

Anti-Corrosion Finish:

A 5μm pickling oil coat extends the cast iron ruler's straight edge life by 2x in humid workshops, outlasting steel rulers that rust or pit from coolants.

Ergonomic Features:

The 30–50mm thick base and rubber handle reduce fatigue, while 500–3000mm sizes (custom to 6000mm) avoid steel’s warping issues over 2000mm.

4. When to Choose Cast Iron

Ideal for:

Heavy-duty environments (foundries, machine shops) with impacts and temperature swings.

Precision-critical tasks like CMM calibration or large casting inspection, where steel’s limitations risk costly rework.

While steel straight rulers suit light use, Storaen’s cast iron metal straightedge and straight edge ruler with handle deliver 3x longer life, superior vibration control, and thermal stability. Backed by a 1-year warranty and custom solutions, they reduce the total cost of ownership for industrial alignment. Explore our range today and experience the precision difference of premium cast iron.

How Straight Rulers Aid in Hand-Scraping Bearing Surfaces

Hand-scraping bearing surfaces demands micron-level precision, and straight rulers are indispensable for guiding accuracy. Storaen’s ruler straight edge solutions enhance this craft, offering rigidity and durability to transform rough surfaces into high-performance interfaces. Here’s how our tools elevate the process:

1. Precision Foundation: Straight Edge Alignment

A metal straight edge ruler is key to verifying flatness:

Surface Inspection: Placing a Storaen stainless steel straight edge ruler (Ra ≤1.6μm) reveals high spots via light gaps, ensuring Class 2 straightness (≤0.02mm/m for 1000mm). This guides precise scraping to create 25–30 contact points/25x25mm, optimizing load distribution in bearings.

Guided Scraping: The rigid edge of our ruler's straight edge ensures consistent scraper angles, preventing uneven cuts. In steam turbines or CNC spindles, this reduces friction by 30% and doubles component life.

2. Material Solutions for Diverse Needs

Storaen offers tailored straight rulers:

Cast Iron Straight Edges (HT200-HT300): With 180–240HB hardness, these resist deflection under 50kg pressure, maintaining ±5μm straightness over 300mm—ideal for heavy-duty applications like diesel engine bearings, where vibrations won’t affect alignment.

Stainless Steel Straight Edge Rulers (304 Grade): Corrosion-resistant with 20μm nickel-chrome plating, they deliver Class 3 straightness (≤0.05mm/m) for marine or medical environments, protecting against coolant and ensuring precision in pumps or medical device bearings.

3. Efficiency & Accuracy in Design

Our metal straight edge ruler optimizes workflow:

Ergonomic Design: A 30mm thick base and rubber grip reduce fatigue during long scraping sessions, while weighted balance ensures stability on vertical/horizontal surfaces—critical for aligning large bearings in wind turbines or presses.

Calibration Assurance: Every ruler meets GB/T 6091-2004 standards via 3D laser scanning, providing a traceable reference for ISO 1101 compliance.

4. Storaen’s Scraping Advantages

Custom Solutions: Bespoke designs like 2000mm ruler straight edge with 120° bevels for curved bearings (4–6 week lead time) suit aerospace or unique geometries.

Durability: Cast iron models feature 5μm pickling oil for rust resistance; stainless steel undergoes passivation, extending tool life by 2x in harsh environments.

Warranty: 1-year protection against dimensional drift ensures confidence in achieving ≤0.01mm/m parallelism, minimizing rework for high-value machinery.

Hand-scraping combines skill and precision, and Storaen’s straight rulers deliver both. From corrosion-resistant stainless steel straight edge ruler to rugged cast iron models, our tools offer the accuracy and durability needed for critical bearings. Elevate your craft with tools designed for modern manufacturing—where every scrape counts toward machinery reliability and performance.

Детальный чертеж продукта

Связанный ПРОДУКТЫ

СВЯЗАННЫЕ НОВОСТИ

Thread Plug Gauge Requires Careful Handling

In the world of manufacturing and engineering, precision is non-negotiable—especially when it comes to threads, which are critical components in machinery, construction, and everyday products.

Surface plate calibration

In today's world, where precision and accuracy are crucial in various industries, the use of granite inspection tables and granite surface plates has become increasingly popular.

Ring Gauge Ensures Machining Accuracy

In the world of precision engineering, manufacturing, and quality control, accuracy is the cornerstone of reliability.