Дек . 10, 2024 07:34 Back to list

200mm Gate Valve Specifications and Applications in Industrial Settings

Understanding the 200mm Gate Valve A Comprehensive Overview

Gate valves are essential components in various industrial applications and plumbing systems. Among the different sizes available, the 200mm gate valve stands out for its robustness and versatility. This article will provide a detailed examination of the 200mm gate valve, discussing its construction, working principles, applications, advantages, and maintenance considerations.

Construction and Design

A 200mm gate valve is designed primarily for regulating flow in pipelines. The main features include a circular body, a gate or wedge mechanism, and a handwheel or actuator for manual or automated operation. The size of 200mm refers to the nominal diameter of the valve, which makes it suitable for medium to high flow applications.

Typically made from durable materials such as cast iron, stainless steel, or ductile iron, these valves can handle different levels of pressure and temperature. The specific material selection often depends on the fluid being transported, whether it’s water, oil, gas, or corrosive chemicals. The internal mechanism involves a gate that moves up and down to control the flow, completely blocking it when closed or allowing it to flow freely when opened.

Working Principles

The operation of a 200mm gate valve is straightforward. When the handwheel is turned, the gate moves vertically within the valve body. In the open position, the gate is lifted, allowing fluid to flow through with minimal resistance. Conversely, when the valve is closed, the gate descends to seal the flow completely, preventing any leakage.

One of the defining characteristics of gate valves is that they are not designed for throttling. While they can provide flow regulation, it’s essential to open or close them fully for optimal performance. Partially opening a gate valve can lead to vibrations, erosion, and even damage over time.

Applications

Due to their robust design, 200mm gate valves are widely used across various sectors. Common applications include

1. Water Supply Systems In municipal water supply networks, gate valves help regulate and manage water flow. 2. Oil and Gas Industry These valves play a crucial role in pipelines transporting crude oil and natural gas, where they help isolate sections of the pipeline during maintenance.

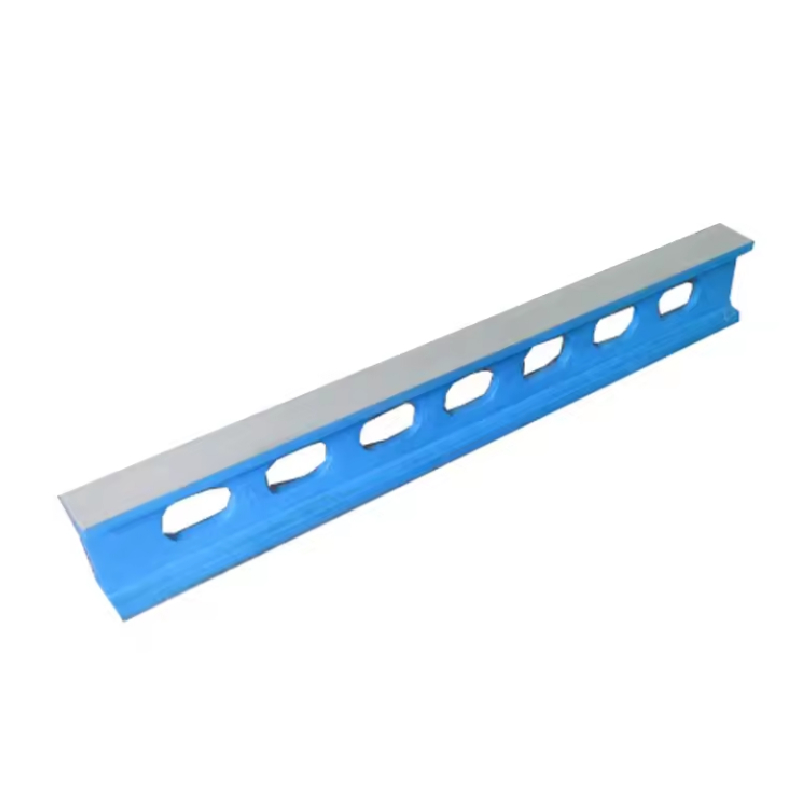

gate valve 200mm

4. Industrial Processes They are used in manufacturing and chemical processing industries, where controlling fluid movement is critical for ongoing operations.

Advantages

The 200mm gate valve offers several advantages

1. Minimal Pressure Drop When fully open, the valve provides a straight, unobstructed flow path, resulting in minimal pressure loss, crucial for efficiency in many applications.

2. Durability Made from robust materials, gate valves are designed to withstand harsh conditions, including high pressures and extreme temperatures.

3. Reliable Sealing When fully closed, the gate valve provides a tight seal, preventing leakage and ensuring safe operation.

4. Low Maintenance With fewer moving parts compared to other valve types, gate valves generally require less maintenance, making them cost-effective over their lifespan.

Maintenance Considerations

While 200mm gate valves are durable, routine maintenance is essential to ensure their longevity and optimal performance. Regular inspections should be conducted to check for signs of wear, corrosion, or other damage. Lubrication of the stem and handwheel mechanism should be performed periodically to ensure smooth operation.

It is also crucial to periodically exercise the valve by opening and closing it fully to avoid any sediment build-up and to ensure the gate moves freely. Operators should be aware of the valve's condition and address any leaks or malfunctions promptly to prevent more extensive damage or operational failures.

Conclusion

The 200mm gate valve is an essential component in a variety of industrial and municipal applications. Its simple design, robust construction, and reliable performance make it a popular choice for managing fluid flow. Understanding its functions, advantages, and maintenance requirements is vital for engineers, operators, and maintenance personnel involved in fluid management systems. By prioritizing proper installation and regular maintenance, users can ensure the efficiency and longevity of these critical devices while minimizing operational risks.

-

thread-plug-gauge-our-promise-of-measurement-excellenceNewsAug.22,2025

-

gauge-pin-class-reflecting-quality-legacyNewsAug.22,2025

-

check-valve-types-for-high-rise-buildingsNewsAug.22,2025

-

water-control-valve-for-irrigation-systemsNewsAug.22,2025

-

gate-valve-with-soft-seal-technologyNewsAug.22,2025

-

y-type-strainer-for-oil-and-gas-applicationsNewsAug.22,2025

Related PRODUCTS