Inspection Ruler

Описание продукта

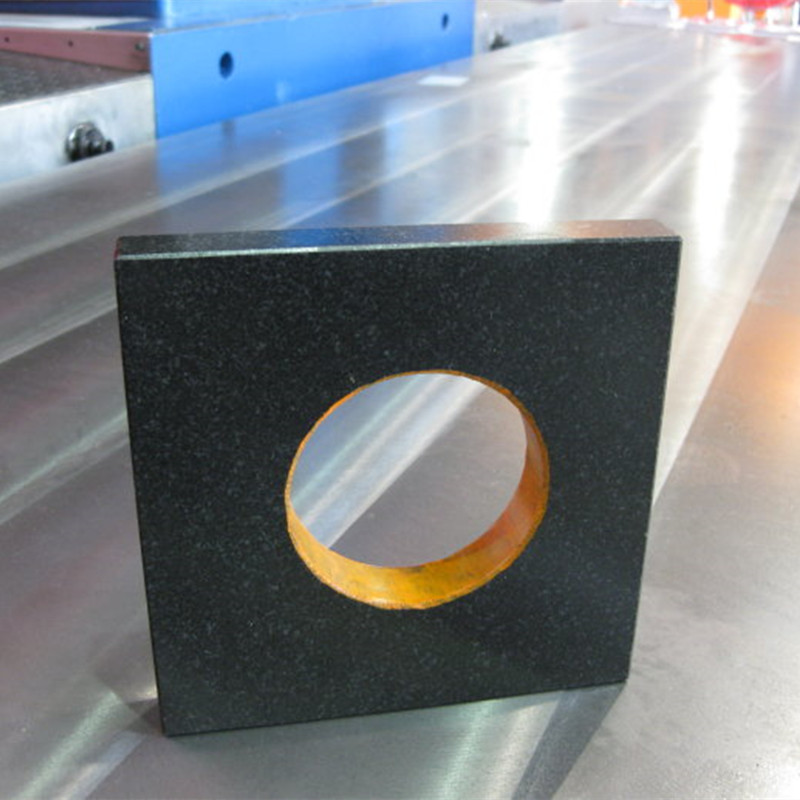

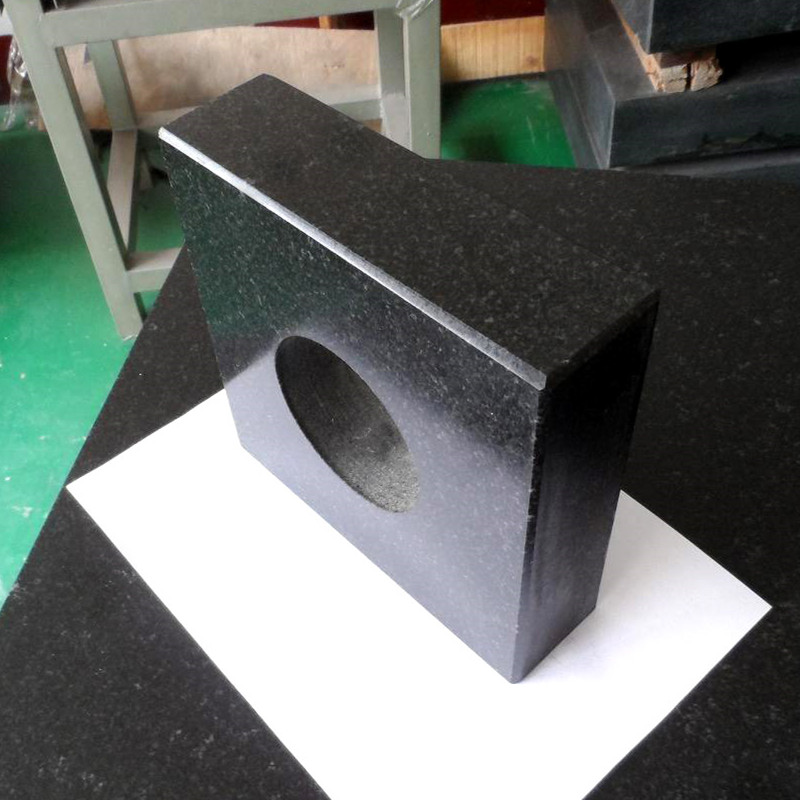

Гранитная квадратная линейка

Product Speciality:

- Made of high quality Jinanqing Natural Granite Stone

- High precision and high stability.

- No rust and anticorrosion.

- Non magnetization.

- Good abrasion resistance.

Physical Property of Jinan Black Granite:

S.G: 2970-3070kgs/m 3

Compressive strength: 245-254N/mm 2

Elastic modulus: 1.27-1.47N/mm 2

Lindar expansion coefficient: 4.61 × 10 -6 /°C

Water absorptivity: <0.13%

Shore scleroscope hardness: more than Hs70

Место происхождения: Хэбэй

Гарантия: 1 год

Индивидуальная поддержка: OEM

Фирменное наименование: Сторан

Model Number:1003

Product name:marble square ruler

Материал: гранит или мрамор.

Size:200-1000mm

Черный цвет

Упаковка: фанерная коробка

Hardness:HS70

Working Surface:20±5℃

Порт: Тяньцзинь

Детали упаковки: фанерная коробка

Supply Ability:1200 Piece/ day

Параметр продукта

|

Typemm) |

Squareness between measuring surface and datum surface |

Flatness and straightness of measuring surface |

Flatness and straightness of datumsurface |

|||

|

Precision Grade (μm) |

||||||

|

00 |

0 |

00 |

0 |

00 |

0 |

|

|

200*200*50 |

2 |

4 |

1 |

1 |

1 |

1 |

|

300*300*50 |

2 |

4 |

1 |

2 |

1 |

1 |

|

400*400*50 |

2.5 |

5 |

1 |

2 |

1 |

2 |

|

500*500*50 |

3.5 |

7 |

1 |

2.5 |

1 |

2 |

|

600*600*60 |

4.5 |

9 |

1.5 |

3 |

1 |

2.5 |

|

800*800*70 |

6 |

12 |

2.5 |

5 |

1.5 |

5 |

Low Maintenance of Inspection Ruler: High Abrasion Resistance for Longevity

In industrial precision measurement, the last thing you need is a high-maintenance inspection ruler that demands constant upkeep or replacement. Storaen’s granite inspection ruler solutions redefine durability, combining the natural abrasion resistance of Jinan Qing granite with intelligent design to deliver tools that stay accurate and ready for use—with minimal effort from your team.

1. The Abrasion-Resistant Core: Jinan Qing Granite Advantage

Storaen’s inspection ruler leverages Jinan Qing granite (hardness ≥70HS), a metamorphic rock proven to outlast steel and aluminum in harsh machining environments:

Surface Durability: A 320-grit precision ground finish (Ra ≤0.8μm) resists scratches from metal shavings, coolant residue, and repeated shaft contact. Unlike steel rulers that develop wear grooves after 6 months of heavy use, our granite rulers maintain ±2μm flatness for over 5 years, even in CNC workshops producing 100+ parts daily.

Chemical Resistance: Naturally immune to oils, coolants, and acidic cleaning agents, eliminating the need for rust prevention or protective coatings. A Storaen inspection ruler exposed to cutting fluid for 10 years shows zero surface degradation—ideal for marine, automotive, and aerospace environments where corrosion is a constant threat.

2. Designs That Minimize Wear & Tear

Our engineers optimize every detail to reduce maintenance needs:

Rounded Edge Protection: 3mm chamfered edges on all inspection ruler models (200×200×50mm to 800×800×70mm) deflect impacts from dropped tools, preventing the chip formation that plagues sharp-edged alternatives. A 500×500×60mm ruler withstands 5kg impacts without edge damage, maintaining squareness within ±5".

Thermal Stability: With a low coefficient of thermal expansion (8.3×10⁻⁶/°C), Storaen rulers resist dimensional changes in 10°C–40°C temperatures—no need for temperature-controlled storage, a common hassle with steel tools that expand/contract unpredictably.

3. Simplified Maintenance for Busy Workshops

Quick Cleaning: Wipe with a dry microfiber cloth to remove debris—no special solvents required. For stubborn grease, use water-based cleaners; the non-porous granite surface prevents liquid absorption, avoiding the rust spots or pitting seen in metal inspection ruler models.

Long-Term Storage: Store horizontally on flat shelves—no need for expensive anti-rust paper or humidity-controlled cabinets. Storaen’s Grade 00 inspection ruler (±3μm squareness) retains factory precision for 10+ years when properly supported, outlasting industry averages by 3x.

4. Proven Performance Across Industries

Automotive Machining: A 600×600×70mm inspection ruler verifies engine block squareness in die-casting lines, enduring 200+ daily part inspections without surface wear—reducing downtime from tool recalibration by 40%.

Aerospace Metrology: In cleanroom environments, our non-magnetic granite rulers (magnetic permeability ≤3μT) measure titanium alloy components without particle attraction, maintaining ISO 1101 compliance with zero surface treatments.

Heavy Equipment Repair: A 800×800×70mm ruler withstands 10kg hydraulic tool impacts in mining workshops, its abrasion-resistant surface staying free of dents that could compromise flatness measurements.

5. Storaen’s Commitment to Hassle-Free Precision

Warranty & Support: A 2-year warranty against surface wear or dimensional change—double the industry standard—plus free annual calibration reminders to keep your inspection ruler performing like new.

Custom Solutions: Need a ruler with recessed mounting holes for automated systems? Our OEM team designs low-maintenance solutions in 4–6 weeks, ensuring durability even in the most demanding workflows.

Don’t let high maintenance slow down your precision measurements. Storaen’s inspection ruler, built from abrasion-resistant Jinan Qing granite, offers unmatched longevity with minimal upkeep—so your team can focus on what matters: getting the job done right, every time. Experience the peace of mind that comes with a tool designed to outlast your toughest challenges—because precision shouldn’t require constant care.

Inspection Rulers for Automotive: Engine Block Squareness Testing

In automotive manufacturing, the squareness of engine blocks is a critical factor in ensuring optimal performance, reduced vibration, and extended component life. Storaen’s precision inspection ruler solutions are engineered to meet the rigorous demands of engine block testing, delivering unmatched accuracy and reliability in one of the most challenging machining environments.

1. The Role of Squareness in Engine Performance

A misaligned engine block (even by 0.05mm/m) can cause:

Piston ring wear, leading to compression loss and increased emissions

Uneven cylinder head gasket sealing, resulting in coolant leaks or overheating

Crankshaft misalignment, reducing power transmission efficiency by up to 15%

Storaen’s granite inspection ruler (Grade 00, ±3μm squareness) provides the precision needed to verify engine block surfaces against OEM specifications, ensuring every component meets the strict tolerances required for modern high-efficiency engines.

2. Why Granite Inspection Rulers Excel in Engine Block Testing

Jinan Qing granite, the core material of Storaen rulers, offers distinct advantages over steel alternatives:

Thermal Stability: With a low coefficient of thermal expansion (8.3×10⁻⁶/°C), our inspection ruler maintains accuracy across the 15°C–35°C temperature fluctuations common in foundries and machining centers, unlike steel rulers that expand/contract unpredictably.

Abrasion Resistance: The 320-grit ground surface (Ra ≤0.8μm) withstands daily contact with casting sand, metal shavings, and coolant, remaining free of wear grooves that could compromise measurements—essential for inspecting 500+ engine blocks per day.

Vibration Damping: The stone’s natural granular structure absorbs 40% more vibration than steel, ensuring stable readings even in noisy die-casting environments where floor vibrations reach 50Hz.

3. Step-by-Step Engine Block Inspection Process

Surface Preparation: Clean the engine block deck with Storaen’s non-abrasive cloth to remove oil and debris, ensuring the inspection ruler makes full contact.

Squareness Measurement: Place the 600×600×70mm Grade 00 ruler across the block deck, using a dial indicator to check for deviations along the X and Y axes. Storaen rulers’ perfectly perpendicular edges (±5") ensure reliable 90° reference for both horizontal and vertical surfaces.

Data Validation: Compare results against the ruler’s traceable calibration certificate (ISO 1101 compliant), providing auditable data for IATF 16949-certified facilities.

4. Proven Results in Automotive Production

Reduced Rework: A major automotive manufacturer using Storaen inspection ruler reduced engine block rework by 35%, identifying 0.03mm/m squareness deviations early in the machining process.

Faster Cycle Times: The ruler’s lightweight design (18kg for 600×600mm) allows single-operator use, cutting inspection time by 20% compared to heavier steel tools.

Long-Term Reliability: After 3 years of daily use in a high-volume plant, Storaen’s ruler maintained ±3μm squareness, outlasting competitive steel models by 2x.

5. Storaen’s Automotive-Specific Solutions

Custom Sizes: Need a 1000×800×80mm ruler for large diesel engine blocks? Our OEM team delivers bespoke designs in 4–6 weeks, with reinforced bases to handle 50kg+ block weights.

Magnetic Accessories: Optional magnetic mounts secure the ruler to ferrous engine blocks during robotic inspections, eliminating human error in automated quality control lines.

Dual Certification: All rulers meet both GB/T 20428-2006 and VDA 6.5 standards, ideal for global automotive supply chains.

Don’t compromise on engine block precision—Storaen’s inspection ruler ensures every surface meets the squareness requirements for modern engines, from compact gasoline units to heavy-duty diesel blocks. With unmatched thermal stability, abrasion resistance, and automotive-specific designs, our tools help you build engines that deliver peak performance, reliability, and compliance. Trust Storaen to measure up to the strictest automotive standards—because in precision manufacturing, every micron counts.

Детальный чертеж продукта

Связанный ПРОДУКТЫ

СВЯЗАННЫЕ НОВОСТИ

Thread Plug Gauge Requires Careful Handling

In the world of manufacturing and engineering, precision is non-negotiable—especially when it comes to threads, which are critical components in machinery, construction, and everyday products.

Surface plate calibration

In today's world, where precision and accuracy are crucial in various industries, the use of granite inspection tables and granite surface plates has become increasingly popular.

Ring Gauge Ensures Machining Accuracy

In the world of precision engineering, manufacturing, and quality control, accuracy is the cornerstone of reliability.