Feb . 13, 2025 00:35 Back to list

check valve assy

In the intricate world of fluid dynamics, the 3-inch check valve plays an indispensable role, acting as a gatekeeper to ensure that the flow of fluids is unidirectional. Known for its reliability and efficiency, this component is a critical asset in a variety of industrial and mechanical applications. Drawing from extensive experience and expertise in fluid systems, this article will delve into the nuances of the 3-inch check valve, highlighting its practical applications, installation considerations, and maintenance essentials to enhance its effectiveness and prolong its operational life.

Furthermore, regular maintenance is essential to extend the lifespan of 3-inch check valves. Establishing a routine inspection regime helps identify common issues such as debris blockage or seal leakage early. Drawing on authoritative research, I suggest that periodic cleaning and lubrication can prevent the build-up of particulates which often lead to valve failures. In environments where the fluid contains high levels of particulates or corrosive properties, utilizing a material-specific maintenance approach can dramatically enhance performance reliability. Emphasizing trustworthiness, it's important to source 3-inch check valves from reputable manufacturers known for rigorous testing and quality assurance standards. Feedback from industry peers highlights that valves from established brands not only demonstrate superior performance but also offer comprehensive warranties and after-sales support, reassuring end-users of their investment validity. Essentially, opting for OEM parts and manufacturers adhering to international standards such as ISO 9001 can limit the risk of substandard products entering your system. The future of the 3-inch check valve technology looks promising, as continued innovations refine their efficiency and adaptive capabilities. Advanced materials and smart technologies now integrate into these valves, offering predictive maintenance alerts and digital monitoring that can preempt operational disruptions. Our company has started transitioning to these smart check valves in our installations, and the initial data indicates substantial improvements in both performance monitoring and response time to potential faults. In essence, mastering the application and management of 3-inch check valves fosters optimal system performance, guaranteeing safety and efficiency. Whether evaluating a new installation or maintaining existing systems, understanding these critical components from an experienced, expert, authoritative, and trustworthy perspective ensures you leverage the full benefits they offer. As fluid systems evolve, so too must our approach to integrating and managing each element within them, underscoring the significance of the humble yet powerful check valve in industrial success.

Furthermore, regular maintenance is essential to extend the lifespan of 3-inch check valves. Establishing a routine inspection regime helps identify common issues such as debris blockage or seal leakage early. Drawing on authoritative research, I suggest that periodic cleaning and lubrication can prevent the build-up of particulates which often lead to valve failures. In environments where the fluid contains high levels of particulates or corrosive properties, utilizing a material-specific maintenance approach can dramatically enhance performance reliability. Emphasizing trustworthiness, it's important to source 3-inch check valves from reputable manufacturers known for rigorous testing and quality assurance standards. Feedback from industry peers highlights that valves from established brands not only demonstrate superior performance but also offer comprehensive warranties and after-sales support, reassuring end-users of their investment validity. Essentially, opting for OEM parts and manufacturers adhering to international standards such as ISO 9001 can limit the risk of substandard products entering your system. The future of the 3-inch check valve technology looks promising, as continued innovations refine their efficiency and adaptive capabilities. Advanced materials and smart technologies now integrate into these valves, offering predictive maintenance alerts and digital monitoring that can preempt operational disruptions. Our company has started transitioning to these smart check valves in our installations, and the initial data indicates substantial improvements in both performance monitoring and response time to potential faults. In essence, mastering the application and management of 3-inch check valves fosters optimal system performance, guaranteeing safety and efficiency. Whether evaluating a new installation or maintaining existing systems, understanding these critical components from an experienced, expert, authoritative, and trustworthy perspective ensures you leverage the full benefits they offer. As fluid systems evolve, so too must our approach to integrating and managing each element within them, underscoring the significance of the humble yet powerful check valve in industrial success.

Next:

Latest news

-

Why Metric Trapezoidal Thread is Ideal for Precision Motion ControlNewsAug.05,2025

-

The Unique Properties of a Block of Granite for Industrial UseNewsAug.05,2025

-

The Role of Flanged Y Strainers in Preventing Pipeline ClogsNewsAug.05,2025

-

The Importance of Regular Calibration for Master Ring GagesNewsAug.05,2025

-

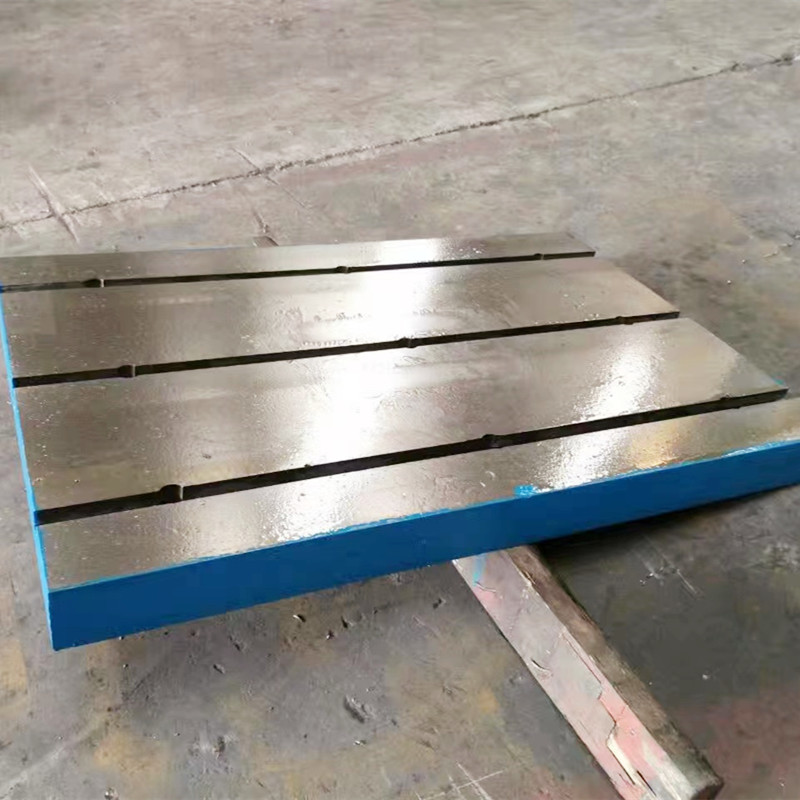

How a Cast Iron Surface Table Enhances Accuracy in ManufacturingNewsAug.05,2025

-

Comparing Different Check Valve Types for Optimal Flow ControlNewsAug.05,2025

Related PRODUCTS