Jan . 15, 2025 01:25 Back to list

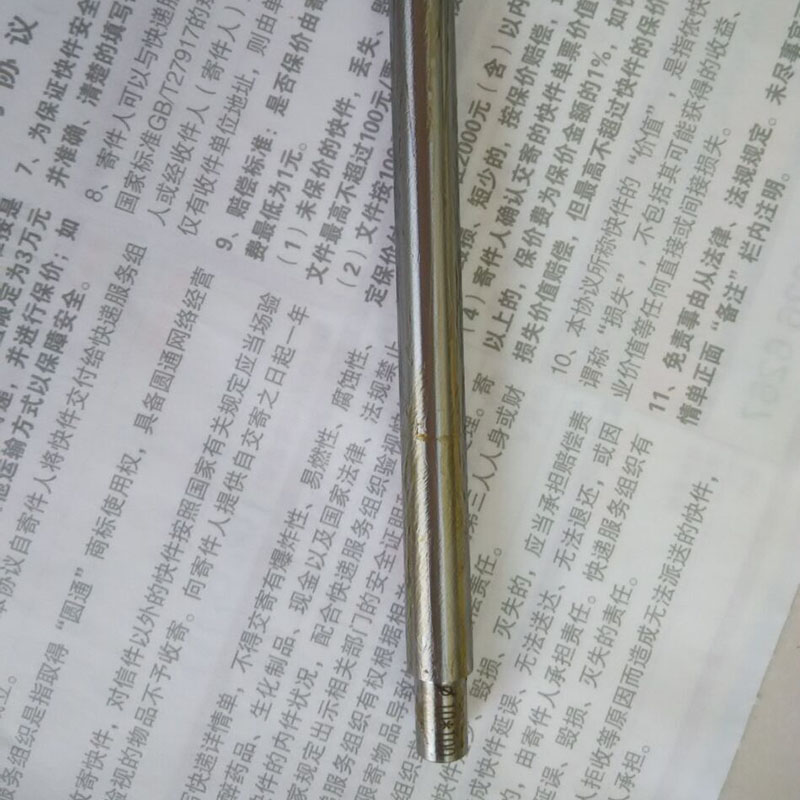

strainer y type flanged

Strainers are a crucial component in a variety of industrial applications, particularly those involving fluid systems. Among the different types of strainers, the Y type flanged strainer stands out due to its superior functionality and adaptability. As someone engaged in the fields of plumbing, engineering, or industrial design, having in-depth knowledge about this particular type of strainer can enhance your system's efficiency and reliability.

Authoritativeness in the field also requires that installers and engineers follow stringent industry standards and practices to ensure that each installation is conducted with precision. Once installed, the regular inspection and maintenance of Y type flanged strainers is key. It not only involves periodic cleaning to remove trapped debris but also the inspection of the strainer body and screen for signs of wear or damage. Implementing a maintenance schedule based on the material and operational conditions optimizes performance and extends the operational life span of the equipment. Furthermore, the trustworthiness of the Y type flanged strainer can be enhanced through rigorous testing and certification by recognized bodies before being deployed in sensitive applications. This provides peace of mind to users and enhances confidence in the system's overall integrity. In an ever-evolving industry landscape, staying informed about product innovations and best practices regarding Y type flanged strainers ensures that one remains at the forefront of technical efficiency and safety. Employing this knowledge practically leads to improved performance outcomes, reduced operational risks, and, ultimately, higher satisfaction among stakeholders across various sectors.

Authoritativeness in the field also requires that installers and engineers follow stringent industry standards and practices to ensure that each installation is conducted with precision. Once installed, the regular inspection and maintenance of Y type flanged strainers is key. It not only involves periodic cleaning to remove trapped debris but also the inspection of the strainer body and screen for signs of wear or damage. Implementing a maintenance schedule based on the material and operational conditions optimizes performance and extends the operational life span of the equipment. Furthermore, the trustworthiness of the Y type flanged strainer can be enhanced through rigorous testing and certification by recognized bodies before being deployed in sensitive applications. This provides peace of mind to users and enhances confidence in the system's overall integrity. In an ever-evolving industry landscape, staying informed about product innovations and best practices regarding Y type flanged strainers ensures that one remains at the forefront of technical efficiency and safety. Employing this knowledge practically leads to improved performance outcomes, reduced operational risks, and, ultimately, higher satisfaction among stakeholders across various sectors.

Next:

Latest news

-

Why Metric Trapezoidal Thread is Ideal for Precision Motion ControlNewsAug.05,2025

-

The Unique Properties of a Block of Granite for Industrial UseNewsAug.05,2025

-

The Role of Flanged Y Strainers in Preventing Pipeline ClogsNewsAug.05,2025

-

The Importance of Regular Calibration for Master Ring GagesNewsAug.05,2025

-

How a Cast Iron Surface Table Enhances Accuracy in ManufacturingNewsAug.05,2025

-

Comparing Different Check Valve Types for Optimal Flow ControlNewsAug.05,2025

Related PRODUCTS