Jul . 02, 2025 09:25 Bwererani ku mndandanda

Granite Box Thickness Standards

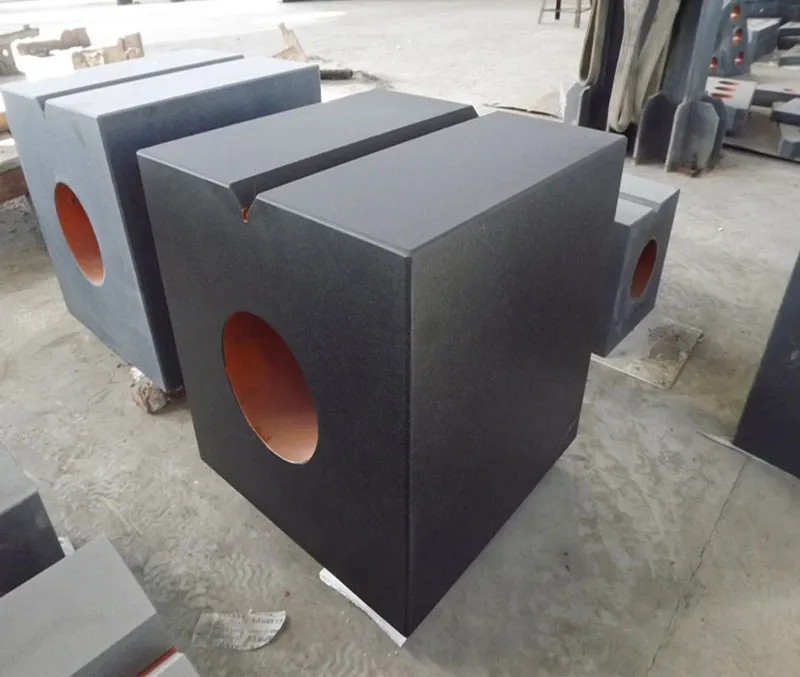

In various industries, granite boxes play a crucial role, whether for precision measurement, architectural applications, or decorative purposes. The thickness of a granite box significantly impacts its performance, durability, and functionality. Storaen (Cangzhou) International Trading Co., a renowned manufacturing company based in Botou, China, has made a name for itself by producing high - quality industrial products. Specializing in cast iron welding platforms, precision measuring tools, and more, their dedication to precision engineering and strict quality control ensures top - tier offerings. A granite square box, typically crafted from Jinan blue stone material through mechanical processing and manual precision grinding, boasts features like a black luster, uniform texture, excellent stability, high strength, and hardness. It can maintain high accuracy under heavy loads and normal temperatures, and offers benefits such as rust - resistance, acid and alkali resistance, wear - resistance, non - magnetization, and shape stability. Understanding the thickness standards for granite boxes, as well as how they relate to block of granite and marble boxes, is essential for ensuring the right product is used for every application.

Thickness Requirements for Different Applications of Granite Box

- Precision Measuring Tools: When used as precision measuring tools, granite boxesneed to have consistent and precise thickness. For example, in metrology laboratories, a granite box with a thickness ranging from 50mm to 100mm is commonly used. This thickness provides sufficient stability and flatness to ensure accurate measurements, allowing the box to withstand the weight of measuring instruments and samples without deforming.

- Architectural and Structural Applications: In architectural projects, granite boxesused for structural support or as decorative elements may require different thicknesses. For load - bearing applications, thicker block of granite - based boxes, often 150mm or more, are preferred to ensure they can bear the weight of the structure and external forces. Decorative marble boxes, on the other hand, might have thinner profiles, around 20 - 30mm, to achieve an elegant appearance while still maintaining adequate strength.

- Decorative and Artistic Creations: For decorative purposes, such as creating artistic granite boxsculptures or ornamental pieces, the thickness can vary widely based on the design concept. Some intricate designs may use granite boxes as thin as 10mm to create a delicate look, while others might incorporate thicker sections, up to 80mm, to add a sense of mass and stability to the artwork.

Processing Techniques and Granite Box Thickness Standards

- Cutting and Shaping: The methods used to cut and shape block of graniteinto granite boxes can affect the achievable thickness. Advanced cutting technologies, such as diamond - wire saws, can create precise and thin cuts, enabling the production of granite boxes with thinner walls. However, traditional cutting methods may have limitations in achieving very thin or highly precise thicknesses, which can influence the overall design and application of the granite box.

- Grinding and Polishing: After cutting, the grinding and polishing processes are crucial for achieving the desired surface finish and thickness accuracy. Skilled craftsmen use specialized equipment to grind down the granite boxto the exact thickness specified, ensuring a flat and smooth surface. In the case of marble boxes, the polishing process not only enhances the aesthetic appeal but also helps in achieving a consistent thickness across the entire surface.

- Assembly and Bonding: When multiple pieces of granite or marble are assembled to form a box, the bonding process can impact the overall thickness and structural integrity. Proper bonding techniques, using high - quality adhesives, ensure that the thickness of the assembled granite boxremains within the required standards and that the box can withstand the intended loads and stresses.

|

Kugwiritsa ntchito |

Typical Thickness Range (mm) |

Rationale |

|

Precision Measuring Tools |

50 - 100 |

Ensures stability and measurement accuracy |

|

Architectural (Load - Bearing) |

≥150 |

Supports structural weight and external forces |

|

Architectural (Decorative) |

20 - 30 |

Balances aesthetics and strength |

|

Decorative Artwork (Delicate) |

10 |

Achieves a delicate appearance |

|

Decorative Artwork (Massive) |

80 |

Adds mass and stability to the design |

Inspection and Quality Control of Granite Box Thickness

- Measurement Tools: To ensure that granite boxesmeet the thickness standards, precise measurement tools are essential. Manufacturers use instruments like calipers, micrometers, and laser measuring devices to accurately measure the thickness at multiple points on the box. These tools can detect even the slightest variations in thickness, ensuring that each granite box adheres to the required specifications.

- Sampling and Testing: Quality control processes often involve sampling a batch of granite boxesfor detailed testing. Randomly selected boxes are thoroughly inspected for thickness consistency, both across the surface and along different axes. This helps identify any potential manufacturing issues and ensures that the entire production batch meets the established thickness standards for granite boxes, block of granite - based products, and marble boxes.

- Documentation and Certification: Maintaining detailed documentation of the thickness measurements and quality control processes is crucial. This documentation serves as proof that the granite boxescomply with the relevant standards. Additionally, obtaining certifications from recognized organizations can further validate the quality and thickness accuracy of the granite boxes, providing customers with confidence in the product's performance.

Granite Box FAQS

Why is the Thickness of a Granite Box Important?

The thickness of a granite box is important for several reasons. In precision measuring applications, the right thickness ensures stability and accuracy, preventing errors caused by deformation under load. For architectural and structural uses, the appropriate thickness guarantees that the granite box can support the required weight and withstand external forces. In decorative applications, thickness impacts the visual appearance and the ability to create the desired design. Overall, the correct thickness is essential for the granite box to function effectively and meet the specific needs of its intended use.

Can the Thickness of a Granite Box Be Customized?

Yes, the thickness of a granite box can often be customized. Manufacturers, like Storaen (Cangzhou) International Trading Co., with their expertise in precision engineering, can produce granite boxes according to specific customer requirements. Whether it's for a unique architectural design, a specialized measuring tool, or a custom - made decorative piece, they can adjust the thickness of the block of granite or marble used to create the perfect granite box for the application.

How Do I Know if a Granite Box Meets the Thickness Standards?

To determine if a granite box meets the thickness standards, you can request documentation from the manufacturer, such as measurement reports and quality control certificates. Additionally, you can use precision measuring tools to measure the thickness of the box at various points. If possible, compare the measurements to the specified standards or consult with experts in the field. Reputable manufacturers, like Storaen (Cangzhou) International Trading Co., are committed to transparency and will be able to provide the necessary information to assure you of the granite box's quality and thickness compliance.

What Happens if the Thickness of a Granite Box is Not Consistent?

If the thickness of a granite box is not consistent, it can lead to various problems. In precision measuring, inconsistent thickness can cause inaccurate readings. For structural applications, it may compromise the load - bearing capacity and stability of the granite box, potentially leading to structural failures. In decorative applications, uneven thickness can affect the visual appeal and the overall quality of the piece. Ensuring consistent thickness is vital for the reliable performance and aesthetic appeal of granite boxes, block of granite - based products, and marble boxes.

Where Can I Find High - Quality Granite Boxes with Standard Thickness?

For high - quality granite boxes that adhere to strict thickness standards, visit the www.strmachinery.com of Storaen (Cangzhou) International Trading Co. With their long - standing reputation for excellence in manufacturing, they offer a wide range of granite boxes, block of granite - based products, and marble boxes. Their commitment to precision engineering and quality control ensures that each product meets the highest standards, providing you with reliable and durable solutions for your various needs. Explore their product offerings and discover the perfect granite box for your projects today!

-

Y Type Strainer Cleaning ProceduresNkhaniJul.02,2025

-

Welding Table Cast Iron Heat ResistanceNkhaniJul.02,2025

-

Spline Ring Gauge Roundness VerificationNkhaniJul.02,2025

-

Ring Gauge Set for Thread InspectionNkhaniJul.02,2025

-

Measurement Platform Surface FlatnessNkhaniJul.02,2025

-

Granite Box Thickness StandardsNkhaniJul.02,2025

Zogwirizana nazo