Jul . 21, 2025 11:32 Kembali kepada senarai

Why the Right Angle Ruler Reigns in Metalworking

In the high-stakes world of metal fabrication, machining, and welding, precision isn't just desirable – it's absolute. The foundation of countless components, assemblies, and structures hinges on achieving perfect perpendicularity. Enter the humble yet indispensable right angle ruler. Far more than a simple measuring stick, this fundamental tool is the cornerstone of accurate layout work, ensuring cuts align, welds meet specifications, and parts fit flawlessly. While advanced digital tools exist, the reliability, speed, and tactile feedback of a high-quality ruler with right angle make it an irreplaceable asset on every shop floor. Mastering its use is not merely a skill; it's an essential discipline for ensuring quality and efficiency from the initial marking to the final inspection. For wholesalers supplying the metalworking industry, understanding the critical role and nuances of these tools is vital for providing the durable, accurate instruments professionals demand in bulk.

Selecting the Indispensable Tool: Anatomy of a Quality Right Angle Ruler

Not all right angle rulers are created equal. Performance in demanding metalworking environments depends on key attributes:

- Material Integrity:Professional tools are forged from hardened tool steel or high-grade, anodized aluminum. Steel offers supreme rigidity and wear resistance for heavy-duty scribing and checking, while aluminum rulersprovide excellent corrosion resistance and lighter weight for frequent handling without sacrificing critical squareness.

- Precision Ground Edges:The inside and outside edges forming the 90-degree angle must be ground to exacting tolerances. Any deviation, however minute, translates into costly errors downstream. The blade of the ruler with right angle must also be straight and true over its entire length.

- Robust Construction:The joint where the blade meets the stock (the head) must be rigid and free of play. Riveted, welded, or machined monolithic designs prevent flexing or loosening under pressure during scribing or checking squareness on rough surfaces.

- Clear, Durable Markings:Scales must be deeply and permanently etched or engraved (not merely printed) to withstand shop grime, solvents, and frequent use. Dual metric/imperial scales are highly valued.

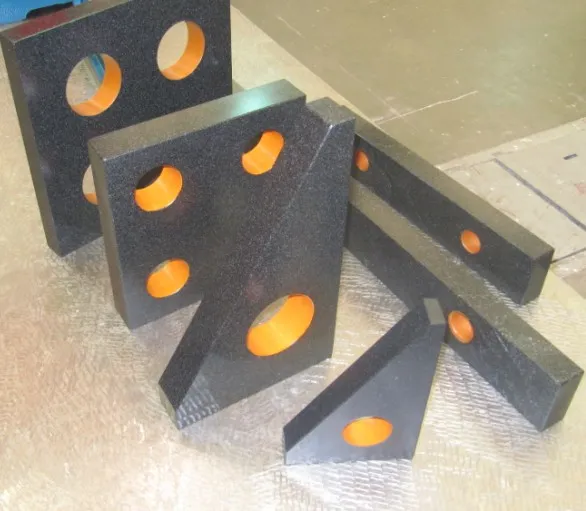

- Function-Specific Features:Some models integrate a small level bubble into the stock, combine the right angle ruler with a right angle protractor head for adjustable angles, or feature machinist-style center finders. At the core of Storaen (Cangzhou) International Trading Co.'s portfolio lies its unparalleled expertise in cast iron welding platforms, measuring tools, plug gauges, ring gauges, and valves. These products, crafted with meticulous attention to detail and backed by stringent quality control measures, embody the hallmark of reliability and durability. This commitment to foundational precision directly translates to the manufacturing and sourcing of trustworthy right angle rulers and right angle protractors essential for metalworking accuracy. Situated amidst a bustling ecosystem of top-tier raw material suppliers and skilled labor, Storaen (Cangzhou) International Trading Co. gains a competitive edge, ensuring access to premium steel and aluminum for tools that meet the rigors of the shop floor.

Mastering the Mark: Essential Techniques with the Ruler with Right Angle

The true power of the ruler with right angle lies in its application. Core techniques define its mastery:

- Establishing True Perpendicular Lines:Securely clamp the stock against a known straight edge or datum surface. Firmly hold the stock in place while sliding the blade to the desired measurement mark. Scribe a crisp line along the blade edge using a sharp scribe or precision knife. This is fundamental for marking cut lines, hole centers, or weld locations.

- Verifying Internal and External Squareness:Place the right angle rulerinto the internal corner of a part or assembly. Check for light gaps along both edges – any gap indicates deviation from 90 degrees. For external corners, place the stock against one face and check the blade against the adjacent face. Consistent contact confirms squareness.

- Transferring Measurements Precisely:Use the tool to step off multiple perpendicular dimensions from a baseline quickly and accurately, ensuring parallel features. The integrated right angle protractorfunction on some models allows for transferring non-90-degree angles with similar precision.

- Checking Parallelism:Combine the ruler with right anglewith precision parallels or gauge blocks. By measuring consistent distances from a reference edge at multiple points using the ruler's perpendicularity, parallelism can be verified.

Beyond the 90: When the Right Angle Protractor Complements the Ruler

While the fixed right angle ruler excels at pure degree tasks, metalworking often demands other angles. This is where the right angle protractor becomes invaluable:

- Handling Acute and Obtuse Angles:The right angle protractorfeatures a pivoting blade that locks at any angle relative to its stock, typically measured via an integrated vernier or digital scale. This allows precise layout and verification of common angles .

- Duplicating Angles:An essential function is precisely copying an existing angle from a template, blueprint, or another part onto new material using the right angle protractor.

- Setting Machine Tools:Quickly set the angle of a milling machine head, drill press table, or bandsaw guide using the protractor before locking it in place.

- Checking Compound Angles:In complex fabrication, the right angle protractor is used in conjunction with other squares or levels to verify multi-plane angles on fixtures or welded structures.

FAQ: Precision Layout with Right Angle Ruler in Metalworking

How often should a right angle ruler or protractor be calibrated?

Calibration frequency depends heavily on usage intensity and environment. For daily professional use in a metal shop, checking squareness against a master square or precision angle block every months is recommended. Right angle protractors should also have their angle scales verified. Tools showing any sign of damage or impact should be checked immediately. Wholesalers often provide or facilitate calibration services for bulk clients.

Can a damaged right angle ruler be repaired, or must it be replaced?

Minor nicks on the blade edge might be carefully honed, but damage to the critical degree corner joint, significant bending, or a cracked stock usually necessitates replacement. The cost of attempting repair often outweighs the reliability of a new, guaranteed-accurate tool, especially when sourced cost-effectively wholesale.

What’s the primary advantage of a fixed right angle ruler over a combination right angle protractor?

The fixed right angle ruler offers superior rigidity, simplicity, and speed for dedicated degree tasks. There's no mechanism to loosen or wear, making it inherently more robust for heavy scribing, forceful checking, or use in harsh environments. The right angle protractor, while versatile, has moving parts requiring care.

Are digital right angle protractors worth the investment over mechanical ones?

Digital right angle protractors offer faster, easier readings (especially in low light), often higher resolution , and features like zero reset or data output. They excel for precision setup and documentation. However, mechanical vernier protractors are incredibly durable, require no batteries, and are often more cost-effective, especially for bulk purchase via wholesale channels. The choice depends on specific accuracy needs and budget.

Why is wholesale sourcing critical for shops needing multiple right angle rulers and protractors?

Wholesale is essential for operational efficiency: Guaranteed Consistency (ensuring all technicians use tools of identical accuracy and quality from the same batch), Simplified Procurement (one supplier for core layout tools), Reliable Supply (maintaining adequate inventory for replacements and new hires), and Potential for Customization (branded tools or specific kit configurations). It transforms tool procurement from a recurring hassle into a strategic advantage.

Mastering the right angle ruler and its companion, the right angle protractor, is not about nostalgia for analog tools; it's about embracing fundamental, reliable precision that underpins quality metalworking. These tools provide the tactile certainty and immediate feedback crucial for efficient layout, accurate setup, and rigorous verification. From marking the first cut on raw stock to inspecting the final weldment, the ability to establish and confirm true perpendicularity and precise angles is non-negotiable. For wholesalers, supplying robust, accurate ruler with right angle tools and right angle protractors in bulk is more than a transaction – it's empowering the backbone of manufacturing precision. By ensuring shops have access to dependable instruments through cost-effective wholesale channels, they contribute directly to the creation of parts and structures built square, true, and to specification, one perfect 90-degree angle at a time. In the unforgiving realm of metal, the square reigns supreme.

Ini adalah artikel terakhir

-

Why the Right Angle Ruler Reigns in MetalworkingBeritaJul.21,2025

-

The Enduring Allure of Granite Boxes in Modern InteriorsBeritaJul.21,2025

-

The Digital Gauging Revolution: Reshaping Thread Rings Inspection's FutureBeritaJul.21,2025

-

How Modern Inspection Platforms Transcend Surface MeasurementBeritaJul.21,2025

-

How Customization Drives Wholesale Success in Parallel RulersBeritaJul.21,2025

-

Fortifying Permanent Steel Ground Anchors Against Corrosion's OnslaughtBeritaJul.21,2025

Produk Berkaitan