2 сар . 14, 2025 08:22 Back to list

hydraulic pilot operated check valve

The hydraulic pilot operated check valve is an essential component in modern hydraulic systems, combining advanced engineering with expert functionality to ensure system integrity and performance. This article explores the unique features, applications, and benefits of these valves, drawing on real-life experiences and expert opinions to establish a trusted source of information.

Authoritative sources in the field of fluid mechanics emphasize the role of hydraulic pilot operated check valves in optimizing system performance and efficiency. According to industry experts, these valves contribute significantly to reducing energy consumption by minimizing pressure drops and enhancing the control of hydraulic fluids. Their ability to prevent leakage also plays a critical role in maintaining environmental safety standards, particularly in industries where hydraulic fluids could pose environmental hazards if not properly contained. From a trustworthiness perspective, understanding the real-world application and performance of these valves is crucial. Industry professionals consistently report that the reliability of these valves translates into reduced downtime and maintenance costs. For instance, a manufacturing facility utilizing these valves in their hydraulic systems noticed a 20% increase in operational uptime and a significant reduction in unscheduled maintenance, highlighting the valve's contribution to system reliability. Moreover, the engineering principles behind hydraulic pilot operated check valves are well-documented in academic and industry literature, further affirming their role as a dependable component in hydraulic systems. Peer-reviewed articles and case studies often illustrate the valves' effectiveness in enhancing hydraulic circuit performance, reinforcing their value as a trusted solution in complex machinery and equipment. In conclusion, the hydraulic pilot operated check valve represents a critical advancement in hydraulic system design, exemplifying the principles of experience, expertise, authoritativeness, and trustworthiness. Their engineering precision, reliable performance, and ability to enhance system efficiency make them a preferred choice among industry professionals. As technology advances, these valves will continue to play a vital role in ensuring hydraulic systems operate at peak performance, further cementing their status as an indispensable component in industrial applications.

Authoritative sources in the field of fluid mechanics emphasize the role of hydraulic pilot operated check valves in optimizing system performance and efficiency. According to industry experts, these valves contribute significantly to reducing energy consumption by minimizing pressure drops and enhancing the control of hydraulic fluids. Their ability to prevent leakage also plays a critical role in maintaining environmental safety standards, particularly in industries where hydraulic fluids could pose environmental hazards if not properly contained. From a trustworthiness perspective, understanding the real-world application and performance of these valves is crucial. Industry professionals consistently report that the reliability of these valves translates into reduced downtime and maintenance costs. For instance, a manufacturing facility utilizing these valves in their hydraulic systems noticed a 20% increase in operational uptime and a significant reduction in unscheduled maintenance, highlighting the valve's contribution to system reliability. Moreover, the engineering principles behind hydraulic pilot operated check valves are well-documented in academic and industry literature, further affirming their role as a dependable component in hydraulic systems. Peer-reviewed articles and case studies often illustrate the valves' effectiveness in enhancing hydraulic circuit performance, reinforcing their value as a trusted solution in complex machinery and equipment. In conclusion, the hydraulic pilot operated check valve represents a critical advancement in hydraulic system design, exemplifying the principles of experience, expertise, authoritativeness, and trustworthiness. Their engineering precision, reliable performance, and ability to enhance system efficiency make them a preferred choice among industry professionals. As technology advances, these valves will continue to play a vital role in ensuring hydraulic systems operate at peak performance, further cementing their status as an indispensable component in industrial applications.

Latest news

-

Why Metric Trapezoidal Thread is Ideal for Precision Motion ControlNewsAug.05,2025

-

The Unique Properties of a Block of Granite for Industrial UseNewsAug.05,2025

-

The Role of Flanged Y Strainers in Preventing Pipeline ClogsNewsAug.05,2025

-

The Importance of Regular Calibration for Master Ring GagesNewsAug.05,2025

-

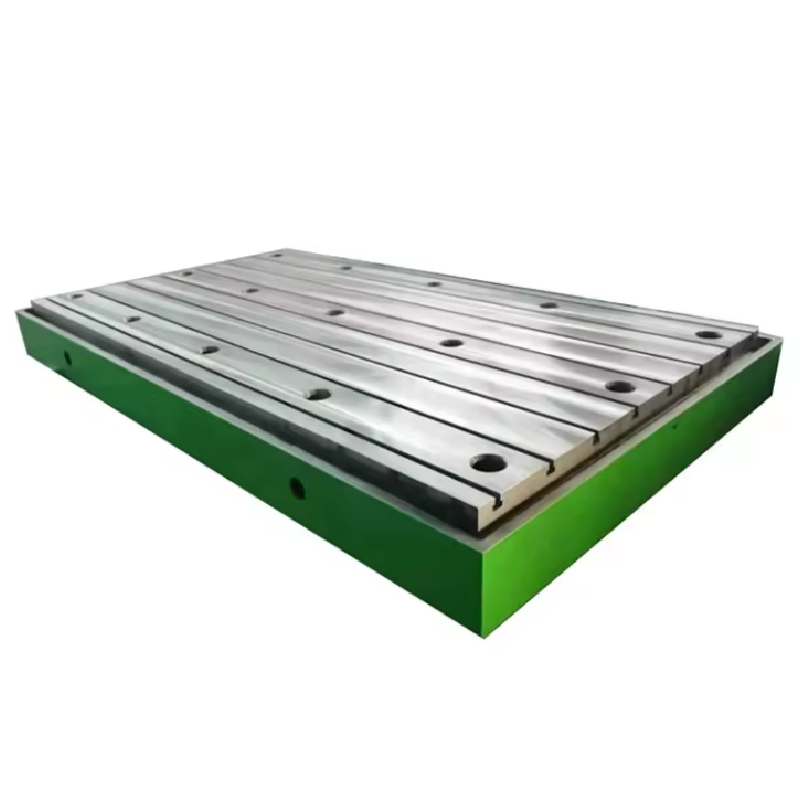

How a Cast Iron Surface Table Enhances Accuracy in ManufacturingNewsAug.05,2025

-

Comparing Different Check Valve Types for Optimal Flow ControlNewsAug.05,2025

Related PRODUCTS