6-р сар . 26, 2025 14:25 Жагсаалт руу буцах

Custom Spline Ring Gauge Design for Unique Engineering Needs

In the world of precision engineering, components like spline ring gauges play a pivotal role in ensuring the accuracy and functionality of mechanical systems. As industries evolve, the demand for specialized tools tailored to unique applications has grown exponentially. Custom сплайн хэмжигч design addresses these needs by offering solutions that align with specific dimensional, material, and operational requirements. This article explores the critical aspects of spline ring gauge manufacturing, design principles, adherence to spline gauge standards, and answers common questions about their application.

The Role of Spline Ring Gauges in Precision Manufacturing

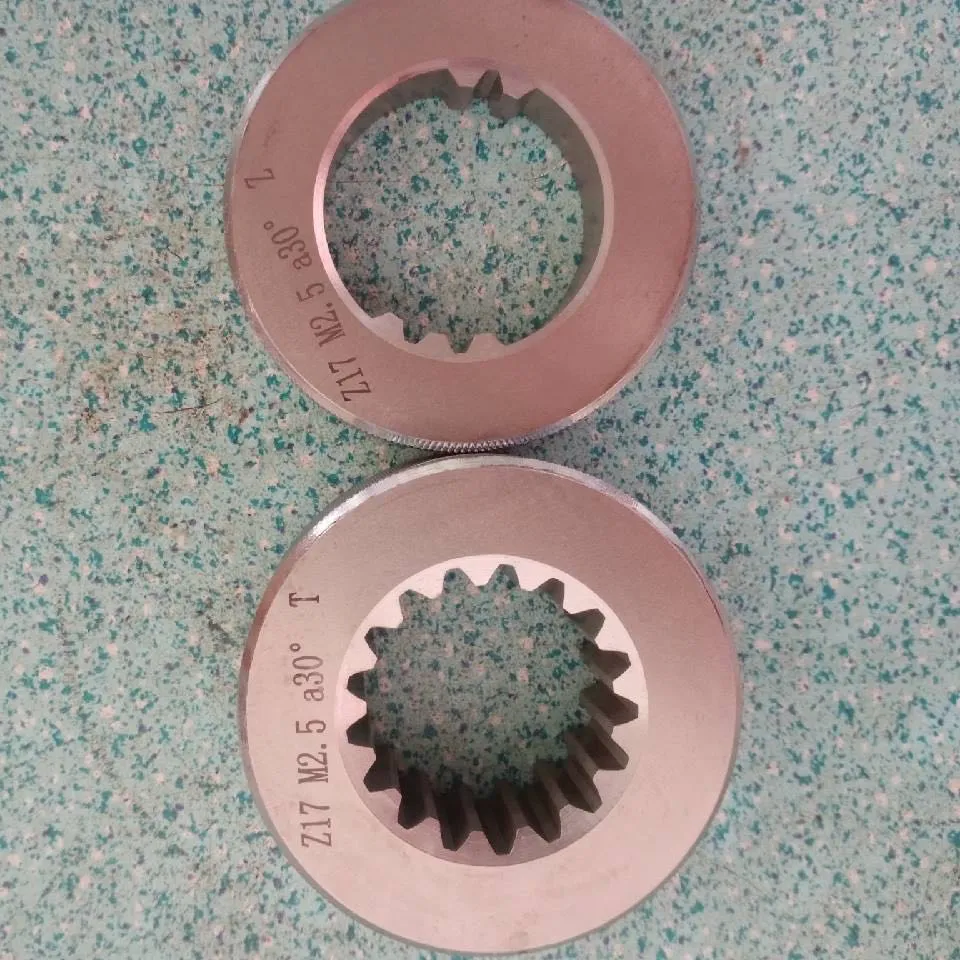

Spline ring gauges are indispensable tools used to verify the accuracy of splined components, such as shafts and gears. These gauges ensure that the splines’ form, fit, and function meet exact specifications, which is vital for industries like aerospace, automotive, and heavy machinery. A spline ring gauge typically consists of a cylindrical ring with internal splines that mirror the external splines of the component being tested. By sliding the part into the gauge, engineers can quickly assess whether tolerances are within acceptable limits.

The need for customization arises when standard gauges cannot accommodate unique spline profiles or non-standard materials. For example, high-temperature applications may require spline ring gauges made from heat-resistant alloys, while corrosive environments might demand stainless steel or coated variants. Custom designs also cater to complex geometries, such as asymmetric splines or hybrid profiles that combine multiple tooth forms.

Manufacturers specializing in large-scale production of spline ring gauges leverage advanced CNC machining and grinding technologies to achieve micron-level precision. This capability ensures that even the most intricate designs are replicated consistently across batches, maintaining uniformity in quality control processes.

Key Considerations in Spline Gauge Design for Custom Applications

Designing a сплайн хэмжигч requires a deep understanding of both engineering principles and end-user requirements. The process begins with a thorough analysis of the component’s specifications, including spline type (involute, straight-sided, or serrated), pressure angle, pitch diameter, and tolerance grades.

One critical factor in spline gauge design is material selection. While tool steel is common for its durability, applications involving high wear may necessitate carbide or ceramic composites. Heat treatment processes, such as nitriding or case hardening, further enhance wear resistance and longevity.

Another consideration is the gauge’s calibration and traceability. Custom spline gauges must align with international measurement standards, ensuring compatibility with third-party inspection systems. Advanced manufacturers employ coordinate measuring machines (CMMs) and optical comparators to validate dimensions before mass production.

Finally, ergonomic design elements, such as lightweight construction or anti-slip surfaces, improve usability in high-volume inspection environments. These refinements reduce operator fatigue and minimize measurement errors during repetitive tasks.

Adhering to Spline Gauge Standards While Meeting Unique Requirements

Global spline gauge standards, such as ISO 4156, ANSI B92.2M, and DIN 5480, provide frameworks for dimensional consistency and interchangeability. These standards define parameters like tooth thickness, root clearance, and allowable deviations, ensuring that components function seamlessly across supply chains.

However, custom applications often require deviations from these norms. For instance, a military project might mandate tighter tolerances than those specified in ISO 4156 to meet extreme durability requirements. In such cases, manufacturers collaborate closely with clients to develop spline gauge designs that balance compliance with practicality.

To achieve this balance, engineers use finite element analysis (FEA) to simulate stress distribution and predict wear patterns under operational conditions. This data-driven approach ensures that custom spline ring gauges meet performance expectations without compromising adherence to foundational standards.

Documentation is equally critical. Each custom сплайн хэмжигч is accompanied by a certification report detailing its compliance with relevant standards, calibration history, and material specifications. This transparency builds trust in industries where traceability is non-negotiable.

FAQs About Spline Ring Gauges and Their Applications

What industries commonly use spline ring gauges for quality control?

Spline ring gauges are widely used in automotive, aerospace, defense, and energy sectors. They ensure the accuracy of transmission shafts, gearboxes, rotor assemblies, and other splined components critical to mechanical systems.

How does material choice impact the lifespan of a spline gauge?

Materials like carbide or hardened steel significantly extend a сплайн хэмжигч’s lifespan, especially in high-wear environments. Coatings such as titanium nitride (TiN) further enhance resistance to abrasion and corrosion.

Can a spline gauge design accommodate non-involute spline profiles?

Yes. Advanced CNC machining allows manufacturers to produce spline gauges with custom profiles, including serrated, triangular, or hybrid splines, to meet specialized engineering needs.

Why is adherence to spline gauge standards important for global suppliers?

Compliance with standards like ISO 4156 ensures that components are interchangeable across international supply chains. This uniformity reduces production delays and guarantees compatibility with third-party inspection tools.

What lead time is typical for large-volume spline ring gauge orders?

Lead times vary based on design complexity, but manufacturers with automated workflows can typically deliver bulk orders within 4–6 weeks, including design validation and quality assurance steps.

Custom spline ring gauge design bridges the gap between standardized manufacturing and unique engineering challenges. By prioritizing precision, material innovation, and compliance with spline gauge standards, manufacturers empower industries to achieve unparalleled quality and reliability. Whether for aerospace innovations or automotive advancements, tailored spline gauges remain a cornerstone of modern precision engineering, ensuring that every splined component performs flawlessly in its intended application.

-

Wear Resistance Strategies for Trapezoidal ThreadsМэдээJun.26,2025

-

Selecting Thread Gauge Types for Aerospace Component InspectionsМэдээJun.26,2025

-

Ring Gauge Influence on Cigar Aging Potential and Storage SolutionsМэдээJun.26,2025

-

Pin Gauge Training Programs for Enhanced Dimensional Inspection SkillsМэдээJun.26,2025

-

Custom Spline Ring Gauge Design for Unique Engineering NeedsМэдээJun.26,2025

-

Cost-Effective Alternatives to Custom Threaded Ring GaugesМэдээJun.26,2025

Холбоотой бүтээгдэхүүн