Jan . 16, 2025 05:37 Back to list

Electric soft seal gate valve

Gate valves are quintessential components in the realm of fluid control systems across various industries. Their primary function lies in managing the flow of liquid or gas along a pipeline, offering either full flow or a full shut-off solution. What sets gate valves apart is their ability to seal tightly, thus, preventing any leakage which is paramount in industries where fluid integrity is sacrosanct.

Authentic experience in installing and maintaining gate valves is instrumental in enhancing their operational lifespan. Regular inspection and maintenance routines deter premature wear and tear, and foresight in the potential for scale or sediment build-up in the valve seat area allows for proactive cleaning protocols. Such maintenance philosophies ensure that gate valves perform optimally, reducing the risk of service interruptions and costly downtime. Gate valves also support a wide range of modifications, providing bespoke solutions that cater to specific industrial needs. Options such as rising stem and non-rising stem designs cater to familiar requirements — visibility on the operational status and space constraints, respectively. Likewise, the choice between manual or automated gate valves can transform the operational dynamic of an industrial system, providing greater control and flexibility in system design. With the increasing importance of sustainable operations, gate valves are evolving. Innovative designs that promote energy efficiency and reduce ecological footprints are being developed, aligning industrial practices with modern environmental standards. Gate valves engineered with sustainable practices in mind help industries not only meet regulatory demands but also facilitate a greener future. In conclusion, gate valves are multi-faceted devices integral to industrial fluid control, demanding a thorough comprehension of their nuances to fully exploit their potential. The elements of expertise, authority, and trustworthiness converge to offer reassurance in the seamless operation of countless systems relying on the precise control of fluid dynamics. By prioritizing accurate valve selection, regular maintenance, and quality assurance, industries can safeguard their operations while concurrently advancing towards sustainability goals.

Authentic experience in installing and maintaining gate valves is instrumental in enhancing their operational lifespan. Regular inspection and maintenance routines deter premature wear and tear, and foresight in the potential for scale or sediment build-up in the valve seat area allows for proactive cleaning protocols. Such maintenance philosophies ensure that gate valves perform optimally, reducing the risk of service interruptions and costly downtime. Gate valves also support a wide range of modifications, providing bespoke solutions that cater to specific industrial needs. Options such as rising stem and non-rising stem designs cater to familiar requirements — visibility on the operational status and space constraints, respectively. Likewise, the choice between manual or automated gate valves can transform the operational dynamic of an industrial system, providing greater control and flexibility in system design. With the increasing importance of sustainable operations, gate valves are evolving. Innovative designs that promote energy efficiency and reduce ecological footprints are being developed, aligning industrial practices with modern environmental standards. Gate valves engineered with sustainable practices in mind help industries not only meet regulatory demands but also facilitate a greener future. In conclusion, gate valves are multi-faceted devices integral to industrial fluid control, demanding a thorough comprehension of their nuances to fully exploit their potential. The elements of expertise, authority, and trustworthiness converge to offer reassurance in the seamless operation of countless systems relying on the precise control of fluid dynamics. By prioritizing accurate valve selection, regular maintenance, and quality assurance, industries can safeguard their operations while concurrently advancing towards sustainability goals.

Next:

Latest news

-

Why Metric Trapezoidal Thread is Ideal for Precision Motion ControlNewsAug.05,2025

-

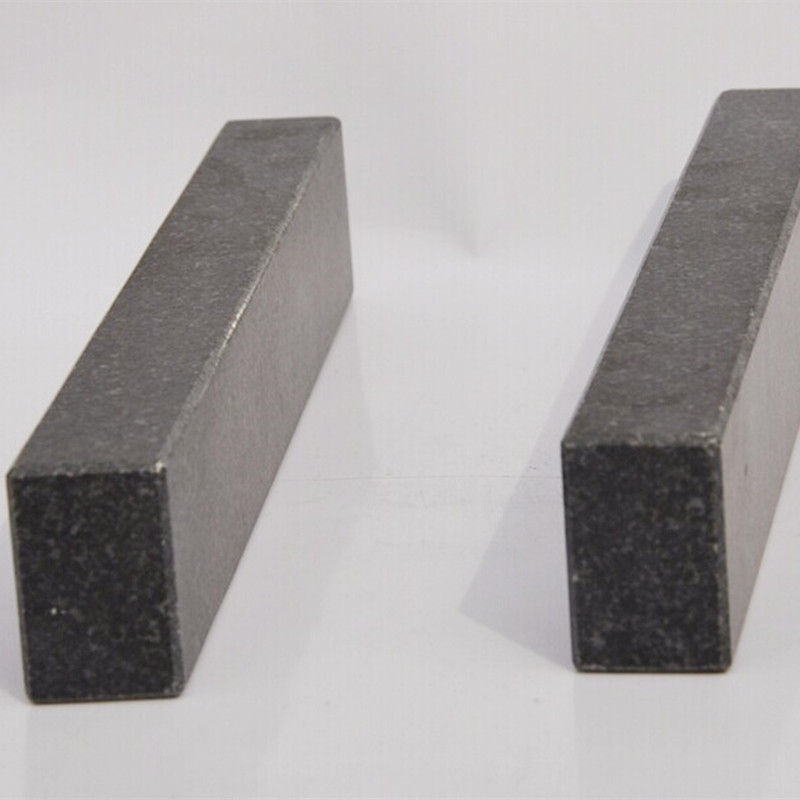

The Unique Properties of a Block of Granite for Industrial UseNewsAug.05,2025

-

The Role of Flanged Y Strainers in Preventing Pipeline ClogsNewsAug.05,2025

-

The Importance of Regular Calibration for Master Ring GagesNewsAug.05,2025

-

How a Cast Iron Surface Table Enhances Accuracy in ManufacturingNewsAug.05,2025

-

Comparing Different Check Valve Types for Optimal Flow ControlNewsAug.05,2025

Related PRODUCTS