Lie . 31, 2025 17:31 Grįžti į sąrašą

Precision Manufacturing with Advanced Spline Gauge Design

As a leading wholesale supplier in the precision measurement industry, Storaen (Cangzhou) International Trading Co. understands the critical role that Spline Gauges play in ensuring manufacturing accuracy. Whether you're inspecting spline shafts for automotive, aerospace, or heavy machinery applications, adhering to Spline Gauge Standards is non-negotiable. In this comprehensive guide, we’ll explore the importance of Spline Gauge Design, the advantages of using these tools, and how they streamline quality control in high-volume production.

Understanding Spline Gauge Design for Optimal Performance

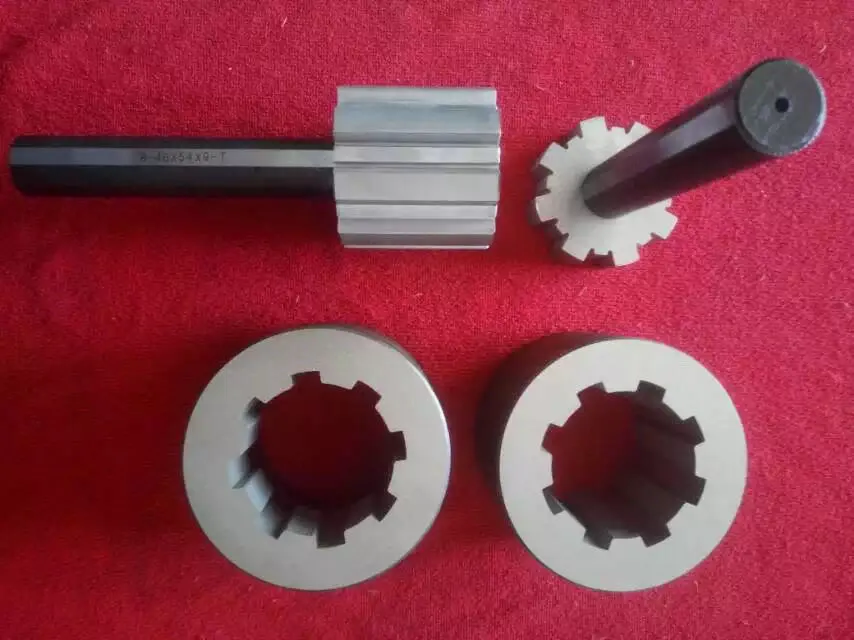

The foundation of an effective Spline Gauge lies in its Spline Gauge Design. A well-engineered gauge ensures precise measurement of spline shaft dimensions, including outer diameter, slot width, and slot depth. The Spline Ring Gauge, for instance, is a specialized tool used to verify these parameters quickly and accurately.

There are two primary types of ring gauges: stop gauges and through gauges. Stop gauges determine the maximum allowable dimensions of a spline shaft, ensuring it does not exceed specified tolerances. Through gauges, on the other hand, confirm whether a spline shaft can pass through, verifying its fit within acceptable limits.

Advantages of Using Spline Ring Gauges:

|

Advantage |

Description |

|

High Accuracy |

Ensures minimal tolerances, reducing defects and improving product quality. |

|

Efficiency in Inspection |

Provides immediate results, speeding up the quality control process. |

|

Measurement Consistency |

Standardizes production, reducing variability from manual measurements. |

|

Reliable Quality Assurance |

Quickly identifies deviations, allowing for prompt corrective actions. |

By integrating these gauges into your workflow, manufacturers can enhance precision while maintaining efficiency—a crucial factor for industries where tight tolerances are mandatory.

Why Spline Gauge Standard Compliance Matters

Adhering to Spline Gauge Standards is essential for maintaining uniformity across manufacturing processes. These standards ensure that every Spline Gauge meets industry-specific requirements, guaranteeing compatibility and interchangeability of parts.

For wholesale buyers, sourcing gauges that comply with recognized Spline Gauge Standards means fewer production delays and higher customer satisfaction. Storaen (Cangzhou) International Trading Co. provides gauges that align with global specifications, ensuring seamless integration into your quality control systems.

Key Applications of Spline Gauges in Industrial Sectors

Spline Gauges are indispensable in industries where precision is critical. Some of the most common applications include:

- Automotive Manufacturing: Ensuring gear shafts and transmission components meet exact specifications.

- Aerospace Engineering: Verifying the integrity of high-stress spline connections.

- Heavy Machinery: Maintaining the durability and performance of large-scale mechanical systems.

By investing in high-quality Spline Gauges, manufacturers can avoid costly reworks and ensure long-term reliability in their products.

Choosing the Right Spline Gauge for Your Needs

Selecting the appropriate Spline Gauge depends on several factors, including the type of spline shaft, required tolerances, and industry standards. Storaen (Cangzhou) International Trading Co. offers a wide range of gauges designed for various applications, ensuring you find the perfect fit for your manufacturing needs.

FAQS about Spline Gauge

What is the primary function of a spline ring gauge in splaino matuoklis applications?

The Spline Ring Gauge serves as a precision inspection tool that verifies critical spline shaft dimensions—including outer diameter, slot width, and depth—against Spline Gauge Standards. By assessing whether components meet exact tolerances, it ensures proper fit and function in mechanical assemblies. This essential Spline Gauge Design element guarantees manufacturing consistency while preventing costly errors in high-precision industries.

How do stop gauges and through gauges differ in splaino matuoklis applications?

Stop gauges verify the maximum permissible dimensions of a spline shaft under Spline Gauge Standards, preventing oversizing. Through gauges test if the shaft fits within the minimum required clearance, ensuring proper assembly. Both types follow strict Spline Gauge Design principles to maintain measurement accuracy in manufacturing quality control processes.

Why is spline gauge standard compliance important?

Compliance with Spline Gauge Standards ensures consistency, reliability, and interchangeability of parts across different manufacturers. It reduces errors and enhances quality control in high-precision industries.

Which industries benefit most from splaino matuokliss?

Industries such as automotive, aerospace, and heavy machinery rely heavily on Spline Gauges to maintain precision in gear and shaft manufacturing, where even minor deviations can lead to significant performance issues.

How does spline gauge design impact measurement accuracy?

A well-optimized Spline Gauge Design ensures tight tolerances and repeatable measurements, minimizing human error and improving overall production efficiency. Proper design also extends the tool’s lifespan, providing long-term cost savings.

In today’s competitive manufacturing landscape, maintaining exacting standards is non-negotiable. By integrating properly designed Spline Gauges into your quality control process, you ensure every component meets rigorous specifications. Storaen (Cangzhou) International Trading Co. provides industry-leading inspection tools that align with global Spline Gauge Standards, giving you the confidence that your products will perform flawlessly. Whether verifying shaft dimensions or confirming assembly tolerances, the right Spline Gauge Design makes all the difference in efficiency and reliability. Don't leave precision to chance - equip your operation with gauges that deliver consistent, trustworthy results every time.

-

Precision Manufacturing with Advanced Spline Gauge DesignžiniosJul.31,2025

-

Industrial-Grade Calibrated Pin Gauges for Exact MeasurementsžiniosJul.31,2025

-

Industrial Filtration Systems Depend on Quality Filter DN50 SolutionsžiniosJul.31,2025

-

High-Performance Gate Valve WholesaležiniosJul.31,2025

-

Granite Surface Plate The Ultimate Solution for Precision MeasurementžiniosJul.31,2025

-

Granite Industrial Tools The Ultimate Guide for Bulk BuyersžiniosJul.31,2025

Susiję produktai