تەموز . 02, 2025 09:28 Vegere navnîşê

Measurement Platform Surface Flatness

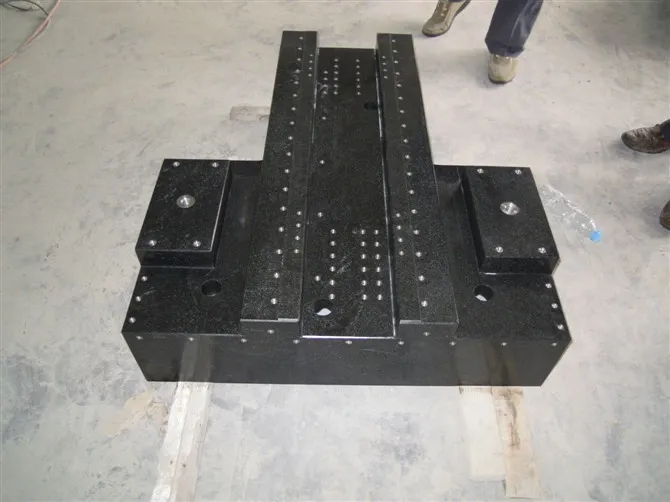

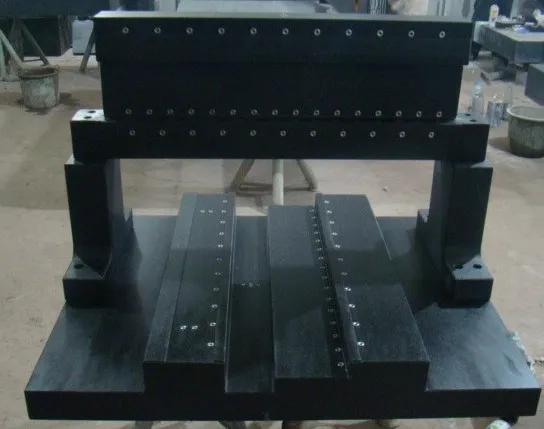

In the world of precision manufacturing and accurate measurement, the measurement platform serves as the foundation for reliable results. Among its various characteristics, surface flatness stands out as a critical factor. Storaen (Cangzhou) International Trading Co., a renowned manufacturing company based in Botou, China, has earned its reputation by specializing in producing high-quality industrial products. From cast iron welding platforms to precision measuring tools, and from different types of plug gauges and ring gauges to valve wholesale, the company's unwavering dedication to precision engineering and strict quality control has made it a trusted name in the industry. Leveraging its strategic location in a major casting hub, the company can access top-notch raw materials and skilled labor, ensuring the superior quality and reliability of its offerings. Whether it's for inspection platforms used in quality control processes or measurement platforms in scientific research, understanding and maintaining surface flatness is essential for accurate platform inspection and successful operations.

The Significance of Surface Flatness in Measurement Platforms

- Accuracy of Measurements: A flat measurement platform surface is crucial for obtaining accurate measurement results. Any irregularities or deviations in the surface can introduce errors, leading to inaccurate readings. For example, in metrology, where precision is of utmost importance, even the slightest unevenness on the measurement platform can cause significant discrepancies in the measurements of components' dimensions, affecting the quality control process that relies on platform inspection of these parts.

- Product Quality Assurance: In manufacturing, inspection platformsare often used to assess the quality of products. A flat surface ensures that products are inspected accurately, helping to identify any defects or non-conformities. If the inspection platform surface is not flat, it may mislead the inspection process, resulting in either accepting defective products or rejecting good ones, which can have serious consequences for production efficiency and product quality.

Methods for Measuring Platform Surface Flatness

- Optical Flats: Optical flats are commonly used to measure the surface flatness of measurement platforms. These are highly polished glass or quartz plates with extremely flat surfaces. By placing an optical flat on the platform and illuminating it with monochromatic light, interference patterns are created. Analyzing these patterns allows technicians to determine the degree of flatness and identify any deviations on the measurement platformsurface during platform inspection.

- Laser Scanning: Laser scanning technology provides a more advanced and comprehensive way to measure surface flatness. A laser scanner emits a laser beam that sweeps across the measurement platformor inspection platform The reflected laser light is then analyzed to create a detailed 3D map of the surface. This method can detect even the smallest irregularities and provides accurate data for platform inspection, enabling precise evaluation of the measurement platform's flatness.

Factors Affecting Measurement Platform Surface Flatness

- Material Properties: The material used to construct the measurement platformor inspection platform significantly impacts its surface flatness. Materials with high stability and low thermal expansion coefficients, such as cast iron, are often preferred. Changes in temperature can cause materials to expand or contract, leading to warping and affecting the surface flatness. Choosing the right material helps maintain the platform's flatness over time and under different environmental conditions during platform inspection.

- Manufacturing Processes: The manufacturing processes employed during the production of measurement platformsalso play a vital role. Precise machining, grinding, and lapping processes are required to achieve a flat surface. Any flaws in these processes, such as uneven cutting or improper grinding techniques, can result in an uneven surface. Storaen (Cangzhou) International Trading Co.'s commitment to precision engineering ensures that their measurement platforms and inspection platforms undergo rigorous manufacturing processes to maintain high surface flatness standards.

|

Factor |

Impact on Surface Flatness |

Explanation |

|

Material Properties |

High |

Stable materials with low thermal expansion resist warping, maintaining flatness |

|

Manufacturing Processes |

High |

Precise machining and finishing ensure a flat surface; errors lead to unevenness |

|

Environmental Conditions |

Moderate |

Temperature, humidity, and vibrations can cause expansion, contraction, or deformation |

|

Usage and Handling |

Moderate |

Rough handling or overloading can damage the platform and affect its flatness |

Standards for Platform Surface Flatness Inspection Platform

- Industry Standards: There are various industry standards that define the acceptable levels of surface flatness for measurement platformsand inspection platforms. These standards provide guidelines for manufacturers and users to ensure consistency and accuracy in platform inspection. For example, standards may specify the maximum allowable deviation from a perfectly flat surface based on the platform's size and intended use, helping to determine whether a measurement platform meets the required quality criteria.

- Custom Requirements: In addition to industry standards, some applications may have custom requirements forsurface flatness. Depending on the specific needs of a project or industry, users may set their own more stringent or relaxed standards for platform inspection. Communicating these custom requirements clearly to manufacturers like Storaen (Cangzhou) International Trading Co. ensures that the measurement platforms and inspection platforms produced meet the exact specifications for accurate and reliable operation.

Measurement Platform FAQS

How Often Should I Inspect the Surface Flatness of a Measurement Platform?

The frequency of platform inspection for surface flatness depends on several factors, such as the platform's usage intensity, the environment it operates in, and the criticality of the measurements. For platforms used frequently in high-precision applications, it is advisable to conduct platform inspection at least once a month. In less demanding environments or for less critical measurements, quarterly or semi-annual inspections may be sufficient. Regular inspections help detect any changes in surface flatness early and ensure the accuracy of measurements.

Can I Repair a Measurement Platform with an Uneven Surface?

In some cases, it is possible to repair a measurement platform with an uneven surface. Minor irregularities can often be corrected through processes like grinding or lapping. However, for more significant damage or warping, it may be more practical to replace the platform. It is recommended to consult the manufacturer or a professional technician to assess the extent of the damage and determine the most appropriate repair method to restore the measurement platform's surface flatness for accurate platform inspection.

What Tools Do I Need for Measuring Platform Surface Flatness?

Common tools for measuring surface flatness of measurement platforms and inspection platforms include optical flats, laser scanners, dial indicators, and interferometers. Optical flats are simple yet effective for basic visual inspection of flatness, while laser scanners offer more detailed and accurate 3D measurements. Dial indicators can be used to measure small deviations from a flat surface, and interferometers provide highly precise measurements by analyzing light interference patterns. The choice of tool depends on the required level of accuracy and the specific characteristics of the platform being inspected.

Does the Size of the Measurement Platform Affect Its Surface Flatness?

The size of the measurement platform can have an impact on its surface flatness. Larger platforms are generally more challenging to manufacture and maintain at a high level of flatness due to factors like material weight, potential warping during manufacturing or transportation, and the difficulty of achieving uniform machining across a larger area. However, with advanced manufacturing techniques and proper quality control measures, manufacturers like Storaen (Cangzhou) International Trading Co. can produce large measurement platforms and inspection platforms with excellent surface flatness suitable for various applications.

Where Can I Purchase High-Quality Measurement Platforms with Guaranteed Surface Flatness?

For high-quality measurement platforms and inspection platforms with guaranteed surface flatness, visit the official website of Storaen (Cangzhou) International Trading Co. With their long-standing expertise in precision manufacturing, commitment to quality, and access to top resources, they offer a wide range of reliable platforms. Explore their product catalog, learn about the different specifications and features, and find the perfect measurement platform or inspection platform to meet your accuracy and platform inspection needs.

Ready to ensure the accuracy and reliability of your measurements? Visit the www.strmachinery.com of Storaen (Cangzhou) International Trading Co. and discover our top-notch measurement platforms and inspection platforms. With guaranteed surface flatness and exceptional quality, our platforms are the perfect choice for all your measurement and inspection requirements.

-

Y Type Strainer Cleaning ProceduresNûçeJul.02,2025

-

Welding Table Cast Iron Heat ResistanceNûçeJul.02,2025

-

Spline Ring Gauge Roundness VerificationNûçeJul.02,2025

-

Ring Gauge Set for Thread InspectionNûçeJul.02,2025

-

Measurement Platform Surface FlatnessNûçeJul.02,2025

-

Granite Box Thickness StandardsNûçeJul.02,2025

Berhemên Têkildar