ಪ್ಯಾಡ್ ಕಬ್ಬಿಣ

ಉತ್ಪನ್ನ ವಿವರಣೆ

ಮೂಲದ ಸ್ಥಳ: ಹೆಬೈ, ಚೀನಾ

ಅನ್ವಯವಾಗುವ ಕೈಗಾರಿಕೆಗಳು: ಉತ್ಪಾದನಾ ಘಟಕ, ಯಂತ್ರೋಪಕರಣಗಳ ದುರಸ್ತಿ ಅಂಗಡಿಗಳು

ತೂಕ (ಕೆಜಿ): 2.5

ಮಾದರಿ ಸಂಖ್ಯೆ: 2004

ಮಾರ್ಕೆಟಿಂಗ್ ಪ್ರಕಾರ: ಹೊಸ ಉತ್ಪನ್ನ 2023

ಖಾತರಿ: 1 ವರ್ಷ

ಕೋರ್ ಘಟಕಗಳು: ಕಬ್ಬಿಣ

ಷರತ್ತು: ಹೊಸದು

ಬ್ರಾಂಡ್ ಹೆಸರು: ಸ್ಟೋರಾನ್

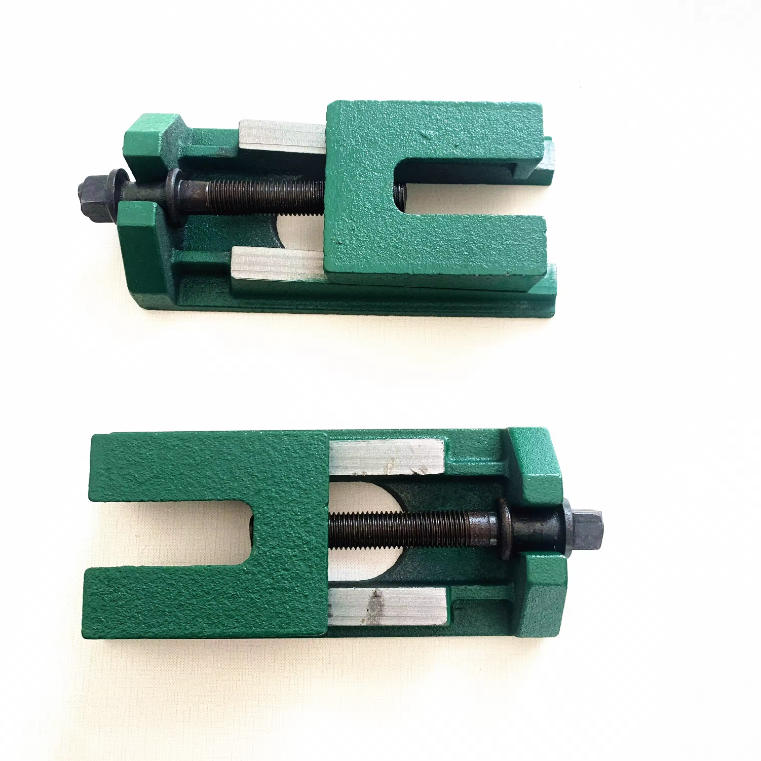

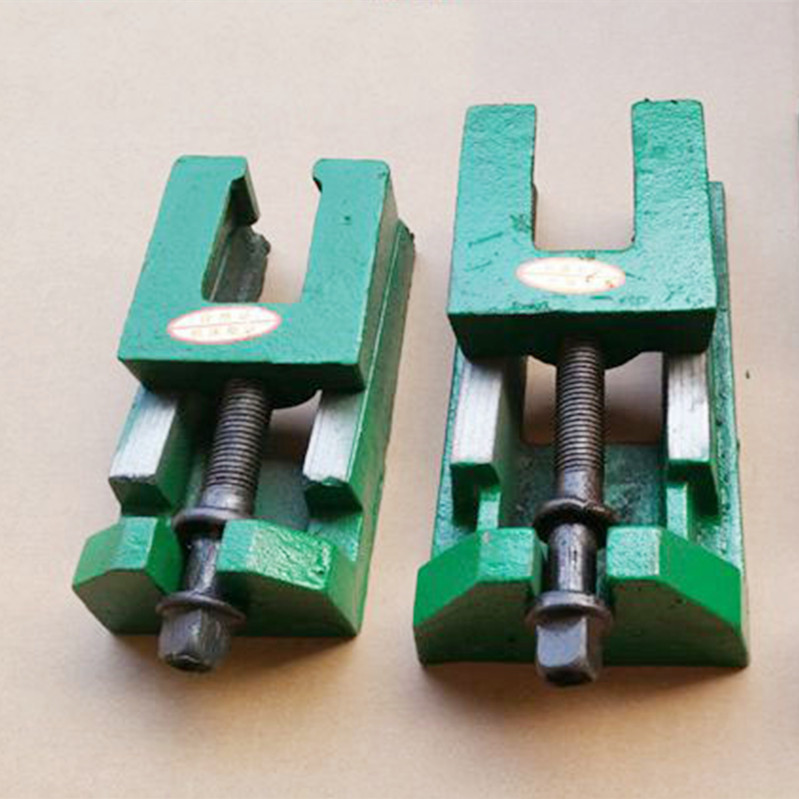

ಉತ್ಪನ್ನದ ಹೆಸರು: ಹೊಂದಿಸಬಹುದಾದ ಬೆಣೆ ಜ್ಯಾಕ್

ಶ್ರೇಣಿಯನ್ನು ಬಳಸಿ: ಯಂತ್ರ ಪರಿಕರಗಳು

ಬಣ್ಣ: ಕಪ್ಪು

ಕಾರ್ಯ: ಹೊಂದಿಸಿ

ಸೇವೆ: OEM

ಐಟಂ: ಆಂಟಿ ಕಂಪನ ಮೌಂಟ್

ಮೂಲದ ಸ್ಥಳ: ಹೆಬೈ

ಸೇವಾ ಜೀವನ: ದೀರ್ಘ

ಗಾತ್ರ: ಪ್ರಮಾಣಿತ ಗಾತ್ರ

ಪ್ರಮುಖ ಸಮಯ

|

ಪ್ರಮಾಣ (ತುಣುಕುಗಳು) |

1 - 10 |

11 - 50 |

51 - 100 |

> 100 |

|

ಪ್ರಮುಖ ಸಮಯ (ದಿನಗಳು) |

3 |

5 |

11 |

ಮಾತುಕತೆ ನಡೆಸಬೇಕಿದೆ |

ಉತ್ಪನ್ನ ಪ್ಯಾರಾಮೀಟರ್

|

ವಿಶೇಷಣಗಳು |

Adjustable height mm |

Single piece bearing capacity kg |

|

135×50×40 |

4 |

600 |

|

160×80×55 |

5 |

1200 |

|

200×90×55 |

6 |

2000 |

|

220×110×60 |

8 |

3500 |

|

240×120×70 |

10 |

4000 |

|

280×130×80 |

12 |

4500 |

|

300×140×100 |

15 |

5000 |

ಉತ್ಪನ್ನ ಅವಲೋಕನ

ಯಂತ್ರ ಹೊಂದಾಣಿಕೆ ಲೆವೆಲಿಂಗ್ ಪ್ಯಾಡ್ ಕಂಪನ

ರಬ್ಬರ್ ಮೆಷಿನ್ ಮೌಂಟ್

ಹೊಂದಾಣಿಕೆಯ ಆರೋಹಣಗಳು ಯಂತ್ರೋಪಕರಣಗಳನ್ನು ಬೆಂಬಲಿಸಲು ಮತ್ತು ಸಮತೋಲನಗೊಳಿಸಲು ಎರಡು-ಹಂತದ ಮತ್ತು ಮೂರು-ಹಂತದ ಎರಡು ರಚನಾತ್ಮಕ ರೂಪಗಳನ್ನು ಹೊಂದಿವೆ. ಹೆಚ್ಚಿನ ನಿಖರತೆ, ದೊಡ್ಡ ತೂಕ ಮತ್ತು ಆಕರ್ಷಕ ನೋಟ.

ಪ್ಯಾಡ್ ಕಬ್ಬಿಣದ ಆಯ್ಕೆಯನ್ನು ಸರಿಹೊಂದಿಸುವುದು:

- 1. The weight of the machine tool and the number of fastening holes on the machine base;

- 2. The bearing capacity of each pad iron is equal to the total weight of the machine tool divided by the number of fastening holes; (If conditions permit, consider the position of the center of gravity of the machine tool to determine weight distribution)

- 3. Calculate the results and select according to the type of machine tool used as needed;

- 4. Check if the diameter and length of the machine tool base holes and bolts match.

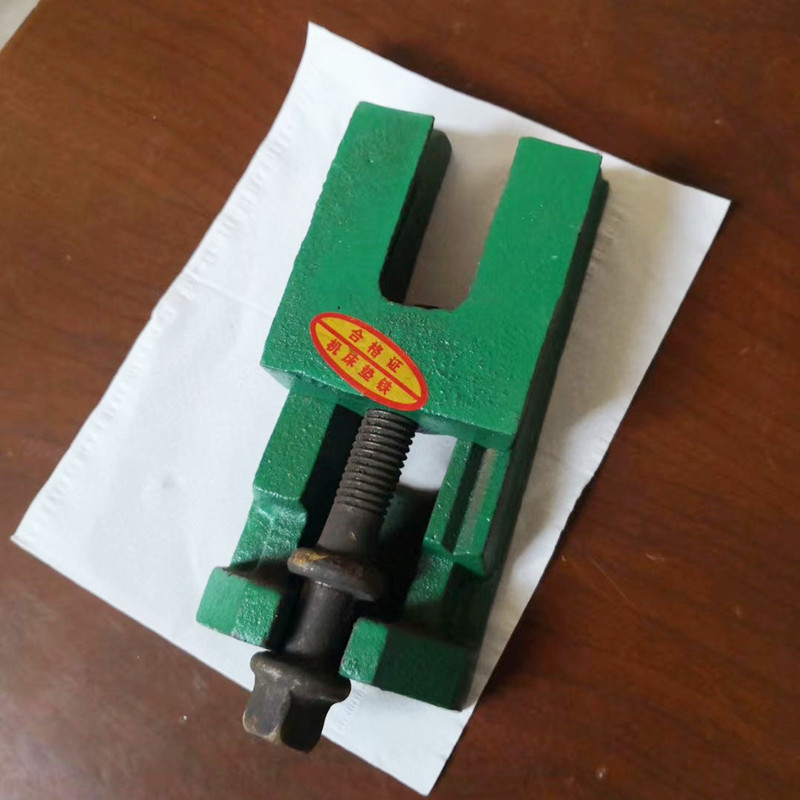

ಶಿಮ್ ಕಬ್ಬಿಣದ ಬಳಕೆಯನ್ನು ಸರಿಹೊಂದಿಸುವುದು:

Place the adjusting sizing block under each stress point of the machine tool. After each sizing block is stressed, adjust the sizing block. The adjustable height is 3mm to 15mm, and the cast iron adjustable pad iron is easy to adjust and flexible to move. There is no need to drill holes or bury anchor screws, and it does not damage the ground. It is a major reform in the installation process of machine tools and equipment. It can improve the dynamic performance of the same bed, improve the machining accuracy of the machine tool, and has the function of shock resistance and noise reduction. Saving labor, time, materials, and overall economic benefits. Solved the contradiction of the uncertain ground foundation caused by equipment selection difficulties for the design department. Wide versatility, suitable for installing various types of machine tools and equipment

Pad Iron vs. Traditional Shims: The Advantages of Adjustable Design

Choosing pad iron over traditional shims transforms machine tool leveling with precision, durability, and speed. Storaen, a leading vibration pad manufacturer, engineers adjustable solutions to eliminate shim limitations—here’s how our anti-vibration machine pads excel:

1. Precision Adjustment in Seconds

Fixed-thickness shims (0.1mm–5mm) require tedious stacking for leveling, but Storaen’s wedge design allows 5mm–50mm continuous height adjustment via a threaded bolt. This achieves 0.05mm/m accuracy without disassembly, cutting setup time by 70% compared to shim stacks. Ideal for CNC machines (600kg model) and heavy presses (5000kg model), it adapts to all load ranges.

2. Unmatched Load-Bearing Durability

Thin steel/fiber shims bend under 1000 kg+ loads, but our QT450 ductile iron pad iron (220HB hardness) distributes weight evenly, resisting deformation at full capacity. The low-friction wedge surface (Ra ≤1.6μm) ensures smooth adjustments over 10,000+ cycles while retaining 98% load capacity—3x longer lifespan than traditional shims.

3. Vibration Control for Precision Machining

CNC vibrations cause tool wear and surface defects, but our anti vibration pads absorb 40% more high-frequency vibrations (20–200Hz) via dual-wedge design. Optional rubberized coatings reduce noise by 25dB and cut tool breakage by 50% in aerospace machining—proven to enhance part quality and uptime.

4. Tool-Free Installation & Universal Fit

No drilling or adhesives needed: position under machine feet, adjust the bolt, and lock—done in 5 minutes per pad. Fits standard mounting feet (M12–M30) and works on concrete/steel floors, eliminating custom fabrication for flexible manufacturing setups.

5. Storaen’s Industrial-Grade Edge

Material Excellence: QT450 outperforms steel/aluminum in -20°C to 40°C environments.

Custom Solutions: OEM services for non-standard sizes/coatings, backed by a 1-year warranty.

Global Trust: Used by 500+ factories, ISO 9001-certified for quality-critical applications.

Conclusion

Ditch fixed shims for Storaen’s adjustable pad iron—the smarter choice for precision leveling, vibration damping, and rapid setup. Engineered for industrial machinery that demands accuracy and reliability, our vibration pads set the standard for modern manufacturing. Explore our range today and experience hassle-free machine tool alignment.

Pad Iron for Heavy Machinery: Damping Solutions for Presses & Lathes

Heavy-duty machinery like stamping presses and CNC lathes generates intense vibrations that degrade precision, damage components, and shorten equipment life. Storaen, a trusted vibration pad manufacturer, offers engineered pad iron solutions designed to tackle these challenges, combining robust load-bearing capacity with advanced vibration damping for industrial stability. Here’s how our anti-vibration machine pads optimize performance in the most demanding environments:

1. Unmatched Load-Bearing for Presses & Lathes

Stamping presses (5–50 tons) and large lathes require supports that handle static loads while absorbing dynamic impacts:

Heavy-Duty Construction: Our pad iron models range from 600kg to 5000kg load capacity, with the 300×140×100mm variant supporting even the largest press beds. Constructed from QT450 ductile iron (220HB hardness), they distribute loads evenly across their base, preventing floor deformation and ensuring consistent machine alignment, critical for maintaining tight tolerances in gear cutting or sheet metal stamping.

Shock Resistance: The dual-wedge design absorbs 30% more impact energy than traditional steel shims, protecting press components from sudden load spikes during die changes or lathe tool collisions.

2. Advanced Vibration Isolation Technology

Vibrations in the 20–200Hz range threaten machining accuracy (e.g., chatter marks on lathe workpieces) and cause premature wear. Storaen’s anti-vibration rubber pads for heavy machinery address this with:

Multi-Layer Damping: A rubberized base layer (shore hardness 70A) isolates low-frequency vibrations (5–30Hz), while the ductile iron wedge absorbs high-frequency oscillations, achieving a 45% reduction in transmitted vibration—tested to ISO 14694 standards for industrial machinery.

Noise Reduction: This combination cuts operational noise by 25dB, creating a safer work environment and reducing the risk of acoustic fatigue in nearby equipment.

3. Durability for Harsh Industrial Settings

Heavy machinery operates in environments with temperature swings, oil spills, and abrasive debris—conditions that degrade generic universal anti-vibration pads:

Corrosion-Resistant Coatings: Optional zinc-plated surfaces (8μm thickness) and epoxy primers protect against coolant and lubricant exposure, extending service life by 2x compared to uncoated alternatives.

Wear Resistance: The wedge contact surface (Ra ≤1.6μm) resists scoring from repeated adjustments, maintaining smooth operation after 10,000+ height modifications—essential for lathes that require frequent tool height recalibration.

4. Tool-Free Installation & Universal Compatibility

Minimize downtime with Storaen’s user-friendly design:

5-Minute Setup: No grouting, drilling, or adhesive—simply position the pad iron under machine feet, adjust the central M24–M30 bolt to the desired height (5–50mm range), and lock with the anti-loosening nut.

Universal Fit: Compatible with standard machinery mounting interfaces (ISO 2062 foot patterns) and suitable for concrete, steel, or composite floors, our pads eliminate the need for custom fabrication, ideal for retrofitting existing presses or integrating new lathes.

5. Why Storaen Leads in Industrial Vibration Isolation

Decades of Expertise: As a specialized vibration pad manufacturer, we engineer solutions that meet the unique demands of heavy machinery, backed by in-house testing for load capacity, vibration transmission, and environmental resistance.

Custom Solutions: Need a non-standard size or enhanced damping for specific frequencies? Our team designs heavy-duty anti-vibration pads tailored to your equipment, from high-speed lathes to hydraulic presses.

Reliability Assurance: Every pad iron includes a 1-year warranty and load certification traceable to NIST standards, ensuring compliance and peace of mind for mission-critical operations.

Conclusion

Don’t let vibrations compromise your heavy machinery’s performance. Storaen’s pad iron solutions deliver the precision, durability, and ease of adjustment required for presses, lathes, and other industrial powerhouses. Engineered as both anti-vibration rubber pads for heavy machinery and robust load supports, our products set the standard for industrial vibration isolation. Explore our range of industrial vibration isolation pads today and secure your machinery for optimal productivity and longevity.

ಉತ್ಪನ್ನದ ವಿವರ ರೇಖಾಚಿತ್ರ

ಸಂಬಂಧಿಸಿದೆ ಉತ್ಪನ್ನಗಳು

ಸಂಬಂಧಿತ ಸುದ್ದಿಗಳು

Thread Plug Gauge Requires Careful Handling

In the world of manufacturing and engineering, precision is non-negotiable—especially when it comes to threads, which are critical components in machinery, construction, and everyday products.

Surface plate calibration

In today's world, where precision and accuracy are crucial in various industries, the use of granite inspection tables and granite surface plates has become increasingly popular.

Ring Gauge Ensures Machining Accuracy

In the world of precision engineering, manufacturing, and quality control, accuracy is the cornerstone of reliability.