មករា . 06, 2025 18:45 Back to list

gate valve types

Valve types play a pivotal role in various industries, including plumbing, HVAC systems, oil and gas, and more. Understanding the different types of valves, their applications, and benefits can significantly enhance operational efficiency and safety. This comprehensive guide delves into the nuances of valve types, offering professional expertise, authority, and trustworthiness to assist you in selecting the right valve for your needs.

Globally, the most popular valve types include gate valves, globe valves, ball valves, butterfly valves, and check valves. Each type serves a distinctive function and varies in design, which impacts its performance and suitability for specific applications.

Gate valves are chiefly used to control the flow of liquid or gas, providing full on or off status. They are ideally suited for operations that require infrequent use, as constantly opening and closing the valve over a short period may cause wear. Known for their low-pressure drop during operation, gate valves are exceedingly efficient in applications where they are either fully open or entirely closed. Industries such as oil and gas exploration and water treatment heavily rely on gate valves for their robust shut-off capabilities.

Globe valves are famous for precise throttling and regulating flow. They offer better solutions for handling fluids that must maintain specific Pressure-Flow characteristics. With their intricate design, globe valves provide a high level of control ideal for operations requiring frequent valve adjustments. Their usage spans across chemical processing industries and power generation facilities where precision control is paramount.

Ball valves feature a spherical disc with a hole through the middle, designed to provide excellent sealing capabilities. These valves are suitable for applications requiring rapid open and close operations. They are used extensively in industries that manage high-pressure systems like hydraulic and pneumatic circuits due to their durability and tight sealing features.

valve types

Butterfly valves are recognized for their lightweight, compact design and cost-effectiveness, making them highly desirable for large volume water applications. Their functionality is often seen in systems where tight shut-off is not necessarily essential, and applications demand quick operations. HVAC systems often employ butterfly valves due to their adaptability and ease of operation in controlling air flow.

Check valves, also known as non-return valves, are instrumental in preventing backflow. They ensure a unidirectional flow of fluids, protecting equipment from potential backflow damage, and maintaining system efficiency. Industries dealing with fluid transfer under pressure, such as sewage systems and industrial process systems, benefit significantly from the reliable performance of check valves.

Selecting the right valve not only hinges on understanding these fundamental types but also involves comprehending the specific demands of the application at hand. Considerations such as pressure, temperature, chemical compatibility, and fluid characteristics are crucial in valve selection. It’s essential to collaborate with valve specialists who can provide in-depth insights into the ideal valve design and material choices to meet technical requirements.

Commitment to safety and quality should guide valve selection and maintenance. Ensuring regular inspections and maintenance regimes is critical to prolonging valve life and preventing system malfunctions. Understanding the complexity and commitment it takes to select and maintain appropriate valve types can substantially increase operational efficiency, ultimately saving time and resources.

Armed with professional knowledge and practical understanding of valve types and applications, businesses can ensure optimal system performance, maintain safety standards, and achieve sustainable operational success.

-

Why Metric Trapezoidal Thread is Ideal for Precision Motion ControlNewsAug.05,2025

-

The Unique Properties of a Block of Granite for Industrial UseNewsAug.05,2025

-

The Role of Flanged Y Strainers in Preventing Pipeline ClogsNewsAug.05,2025

-

The Importance of Regular Calibration for Master Ring GagesNewsAug.05,2025

-

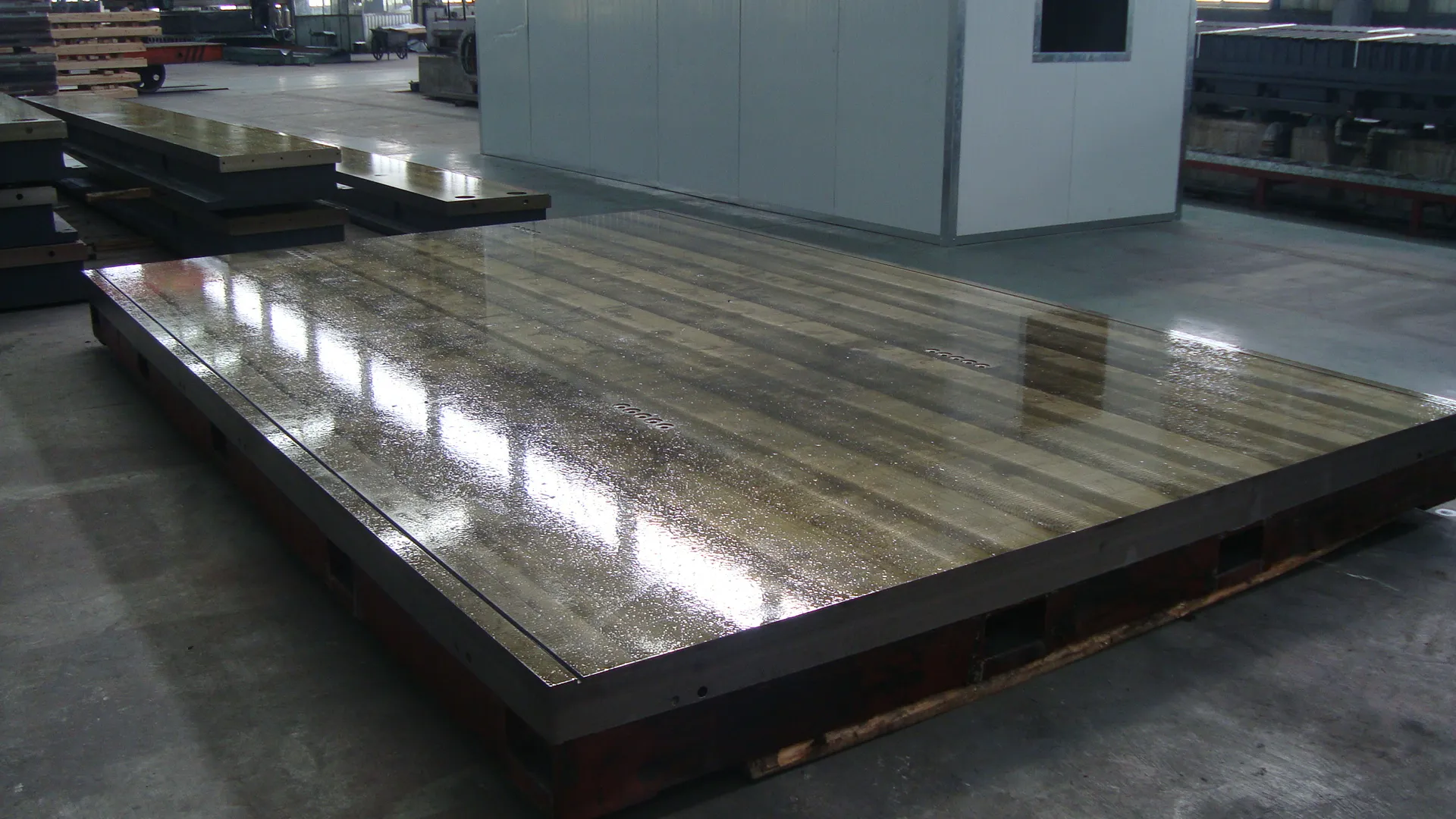

How a Cast Iron Surface Table Enhances Accuracy in ManufacturingNewsAug.05,2025

-

Comparing Different Check Valve Types for Optimal Flow ControlNewsAug.05,2025

Related PRODUCTS