កុម្ភៈ . 10, 2025 12:29 Back to list

Control Valve

Globe control valves are pivotal in numerous industrial applications due to their unique ability to provide precise flow control. Understanding their pricing landscape is crucial for businesses aiming to optimize operational efficiencies and budget effectively. This analysis offers insights into factors influencing the cost of globe control valves and provides guidance for selecting premium quality valves.

Additionally, brand reputation is a non-negligible factor in pricing. Established manufacturers with a long-standing reputation for quality assurance and reliability often command higher prices. Such premium pricing often reflects the company’s investment in research and development, rigorous testing processes, and adherence to international quality standards, factors which contribute to the establishment of trust and reliability in their offerings. Lifetime cost considerations, including maintenance and energy efficiency, should weigh heavily in the purchase decision. High-quality globe control valves, although potentially higher in initial cost, are engineered to minimize energy waste and require less frequent maintenance. Selecting a valve with a lower total cost of ownership can outperform cheaper alternatives when evaluated over its operational lifespan. For enterprises prioritizing both performance excellence and budgetary limits, collaborating with certified suppliers and procuring valves equipped with modern smart features can yield significant advantages. Smart globe control valves, equipped with Internet of Things (IoT) capabilities, can provide real-time data monitoring and predictive maintenance alerts, enhancing both the control and longevity of the valve. In conclusion, the pricing of globe control valves is a complex interplay of various factors including size, material, operational capability, and brand credibility. Professionals seeking to procure these valves should thoroughly evaluate their specific operational needs while considering both upfront and long-term costs. Partnering with reputable manufacturers promises not only superior product performance but also a safeguard for prolonged operational integrity and efficiency. Businesses equipped with this nuanced understanding can make informed decisions which align perfectly with both performance goals and financial constraints.

Additionally, brand reputation is a non-negligible factor in pricing. Established manufacturers with a long-standing reputation for quality assurance and reliability often command higher prices. Such premium pricing often reflects the company’s investment in research and development, rigorous testing processes, and adherence to international quality standards, factors which contribute to the establishment of trust and reliability in their offerings. Lifetime cost considerations, including maintenance and energy efficiency, should weigh heavily in the purchase decision. High-quality globe control valves, although potentially higher in initial cost, are engineered to minimize energy waste and require less frequent maintenance. Selecting a valve with a lower total cost of ownership can outperform cheaper alternatives when evaluated over its operational lifespan. For enterprises prioritizing both performance excellence and budgetary limits, collaborating with certified suppliers and procuring valves equipped with modern smart features can yield significant advantages. Smart globe control valves, equipped with Internet of Things (IoT) capabilities, can provide real-time data monitoring and predictive maintenance alerts, enhancing both the control and longevity of the valve. In conclusion, the pricing of globe control valves is a complex interplay of various factors including size, material, operational capability, and brand credibility. Professionals seeking to procure these valves should thoroughly evaluate their specific operational needs while considering both upfront and long-term costs. Partnering with reputable manufacturers promises not only superior product performance but also a safeguard for prolonged operational integrity and efficiency. Businesses equipped with this nuanced understanding can make informed decisions which align perfectly with both performance goals and financial constraints.

Latest news

-

Why Metric Trapezoidal Thread is Ideal for Precision Motion ControlNewsAug.05,2025

-

The Unique Properties of a Block of Granite for Industrial UseNewsAug.05,2025

-

The Role of Flanged Y Strainers in Preventing Pipeline ClogsNewsAug.05,2025

-

The Importance of Regular Calibration for Master Ring GagesNewsAug.05,2025

-

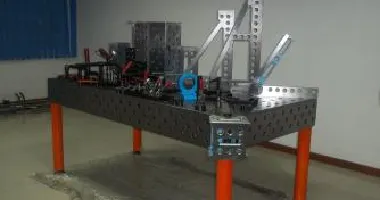

How a Cast Iron Surface Table Enhances Accuracy in ManufacturingNewsAug.05,2025

-

Comparing Different Check Valve Types for Optimal Flow ControlNewsAug.05,2025

Related PRODUCTS