ივლ . 02, 2025 09:36 სიაში დაბრუნება

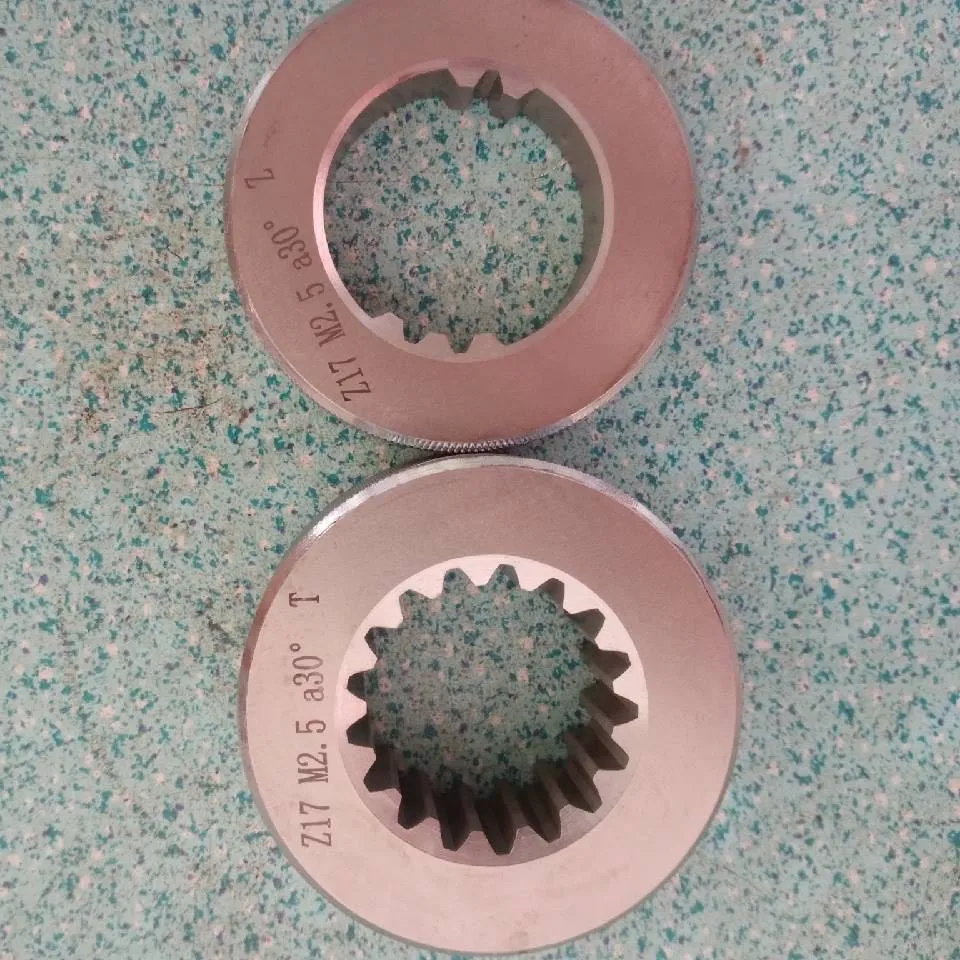

Spline Ring Gauge Roundness Verification

In the intricate world of precision manufacturing, ensuring the accuracy of components is the linchpin of quality and reliability. Spline ring gauges, a vital tool in measuring spline shaft dimensions such as outer diameter, slot width, and slot depth, play a crucial role in maintaining the integrity of mechanical assemblies. Storaen (Cangzhou) International Trading Co., a distinguished manufacturing entity based in Botou, China, has carved a niche for itself by excelling in producing a diverse array of high - quality industrial products. Specializing in cast iron welding platforms, precision measuring tools, various plug gauges, ring gauges, and valve wholesale, the company's unwavering dedication to precision engineering and stringent quality control has earned it a reputation as a trusted industry partner. Leveraging its strategic location in a renowned casting hub, it sources top - tier raw materials and deploys skilled labor, ensuring that every product, including spline ring gauges, meets the loftiest standards. Among the critical aspects of spline ring gauge functionality, roundness verification stands out as a cornerstone for accurate measurements. Properly verified spline ring gauges, whether they are spline go no go gauges or other types, guarantee that spline shafts conform to the required specifications, facilitating seamless assembly and optimal performance of machinery.

The Significance of Spline Ring Gauge Roundness Verification

- Ensuring Measurement Accuracy: The roundness of a spline ring gauge directly impacts the accuracy of measurements it provides. A non - round spline ring gauge can yield incorrect readings for spline shaft dimensions, leading to the acceptance of substandard components. By verifying the roundness of spline ring gauges, manufacturers can trust the measurements taken, ensuring that spline shafts have the correct outer diameter, slot width, and depth, which are essential for proper mechanical function.

- Preventing Assembly Issues: In mechanical assemblies, spline shafts need to fit precisely with mating components. If a spline ring gaugeused for inspection has an improper roundness, it may pass shafts that are actually out of tolerance. This can result in loose fits, vibrations, or even complete assembly failures. Regular roundness verification of spline ring gauges helps prevent such issues, ensuring smooth and reliable assembly processes.

Factors Affecting Spline Ring Gauge Roundness

- Manufacturing Processes: The quality of manufacturing processes has a significant impact on the roundness of spline ring gauges. Inaccurate machining, improper heat treatment, or insufficient finishing can lead to variations in roundness. Storaen (Cangzhou) International Trading Co.'s commitment to precision engineering ensures that each spline ring gaugeundergoes rigorous manufacturing steps to maintain optimal roundness.

- Usage and Handling: Rough handling during use or storage can cause damage to spline ring gauges, affecting their roundness. Dropping the gauge, subjecting it to excessive force, or improper storage in a non - protective environment can lead to deformations that compromise the accuracy of the სლაინ ლიანდაგიand spline go no go gauges.

|

Factor |

Impact on Roundness |

Explanation |

|

Manufacturing Processes |

High |

Inaccurate machining or improper treatment can cause shape deviations |

|

Usage and Handling |

Moderate |

Rough use or storage can lead to physical damage and deformation |

|

Environmental Conditions |

Low |

Temperature and humidity changes may cause minor dimensional variations |

Maintenance of Spline Ring Gauges for Roundness Preservation

- Regular Cleaning: After each use, clean spline ring gaugesthoroughly to remove any dirt, debris, or metal shavings. A clean gauge is less likely to experience wear or damage that could affect its roundness. Use a soft brush and appropriate cleaning agents to ensure a gentle yet effective cleaning process.

- Proper Storage: Store spline ring gaugesin a dedicated case or container that provides protection from external impacts. Keep them in a stable environment with controlled temperature and humidity to prevent dimensional changes that could impact roundness. Organize the gauges carefully to avoid contact with other tools or objects that might cause scratches or deformations.

Spline Ring Gauge Roundness Verification and Other Inspections

- Complementary to Other Checks: Roundness verification of spline ring gaugesis not a standalone process. It works in tandem with other inspections, such as checking the flatness of the gauge surfaces and the accuracy of its measuring features. Together, these inspections ensure that spline gauges and spline go no go gauges are in optimal condition for accurate spline shaft measurements.

- Ensuring Overall Gauge Reliability: By combining roundness verification with other quality checks, manufacturers can have full confidence in the reliability of their spline ring gauges. This comprehensive approach helps maintain the integrity of the entire measurement process, from inspecting spline shafts to ensuring the final assembly meets the highest quality standards.

Spline Ring Gauge AQS

How Often Should I Verify the Roundness of Spline Ring Gauges?

The frequency of roundness verification for spline ring gauges depends on factors like usage frequency and the criticality of the measurements. For gauges used regularly in high - precision applications, it is advisable to verify roundness at least once every few months. In less demanding environments, annual verification may be sufficient. However, if any signs of damage or inconsistent measurements are observed, immediate verification is recommended.

Can I Use a Regular Ruler to Check the Roundness of Spline Ring Gauges?

No, a regular ruler is not suitable for checking the roundness of spline ring gauges. Roundness requires precise measurement of the deviation from a perfect circle at multiple points, which a ruler cannot provide. Specialized tools like roundness testers or optical comparators are designed to accurately assess the roundness of spline gauges and spline go no go gauges.

What Should I Do if a Spline Ring Gauge Fails the Roundness Verification?

If a spline ring gauge fails the roundness verification, first, check for any visible damage or contaminants that could be causing the issue. Clean the gauge thoroughly and repeat the verification. If the problem persists, the gauge may need to be repaired or replaced. Contact the manufacturer, such as Storaen (Cangzhou) International Trading Co., for advice on the best course of action, as they can provide professional repair services or recommend a suitable replacement gauge.

Does the Material of Spline Ring Gauges Affect Their Roundness?

Yes, the material of spline ring gauges can impact their roundness. High - quality materials with good dimensional stability, such as hardened steel or certain alloys, are less likely to deform over time, helping to maintain roundness. Storaen (Cangzhou) International Trading Co. uses top - grade materials in the production of spline ring gauges to ensure long - lasting accuracy and roundness.

Where Can I Purchase High - Quality Spline Ring Gauges for Roundness Verification?

For high - quality spline ring gauges suitable for accurate roundness verification, visit the www.strmachinery.com of Storaen (Cangzhou) International Trading Co. As a leading manufacturer with a focus on precision and quality, they offer a wide range of spline gauges and spline go no go gauges. Explore their product catalog, learn about the specifications and features, and find the perfect spline ring gauges to meet your measurement and verification needs.

-

Why Metric Trapezoidal Thread is Ideal for Precision Motion ControlსიახლეებიAug.05,2025

-

The Unique Properties of a Block of Granite for Industrial UseსიახლეებიAug.05,2025

-

The Role of Flanged Y Strainers in Preventing Pipeline ClogsსიახლეებიAug.05,2025

-

The Importance of Regular Calibration for Master Ring GagesსიახლეებიAug.05,2025

-

How a Cast Iron Surface Table Enhances Accuracy in ManufacturingსიახლეებიAug.05,2025

-

Comparing Different Check Valve Types for Optimal Flow ControlსიახლეებიAug.05,2025

Მსგავსი პროდუქტები