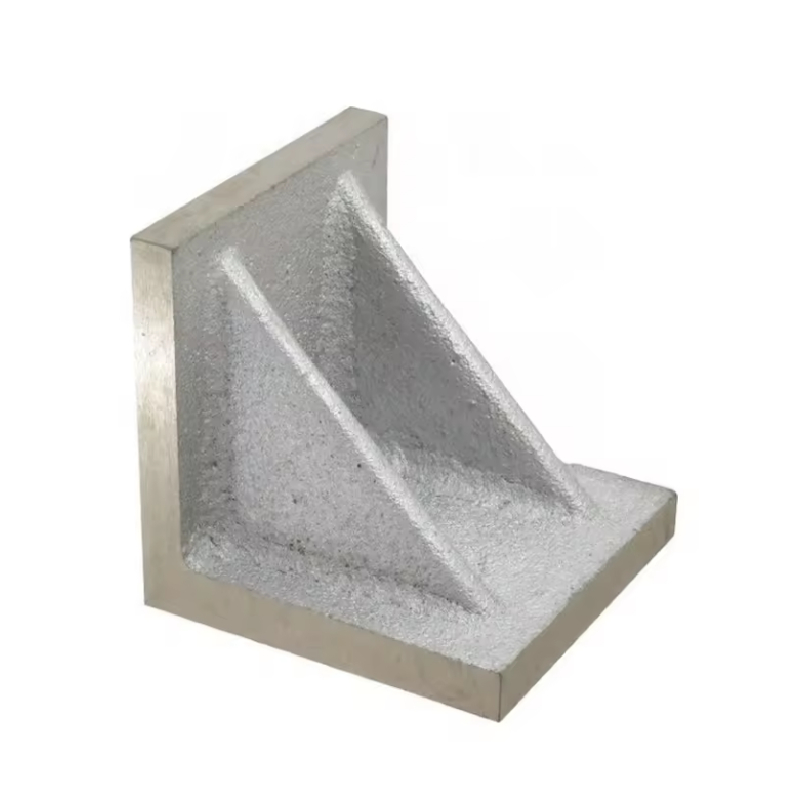

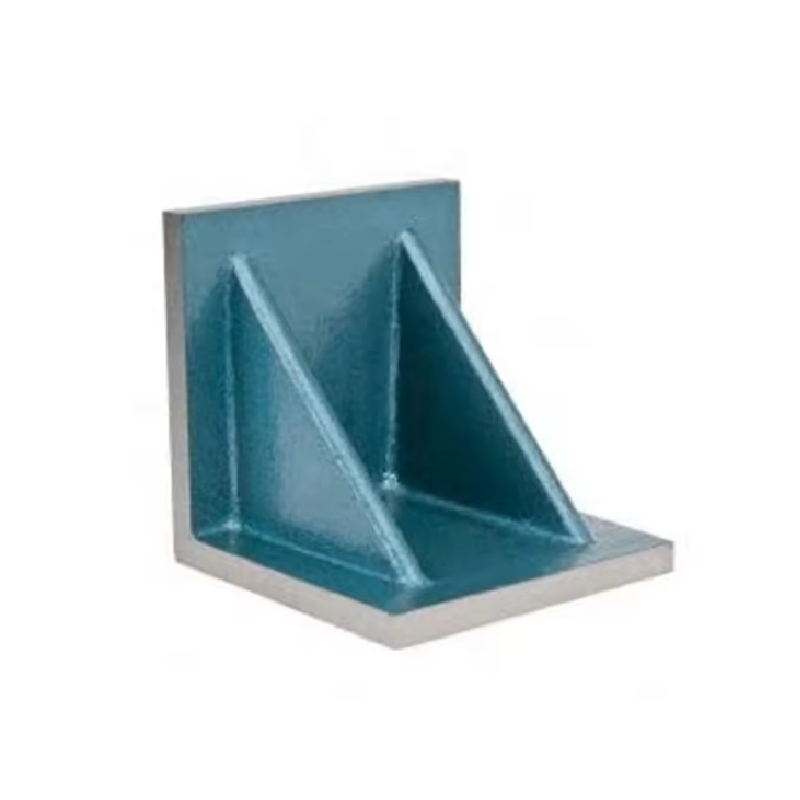

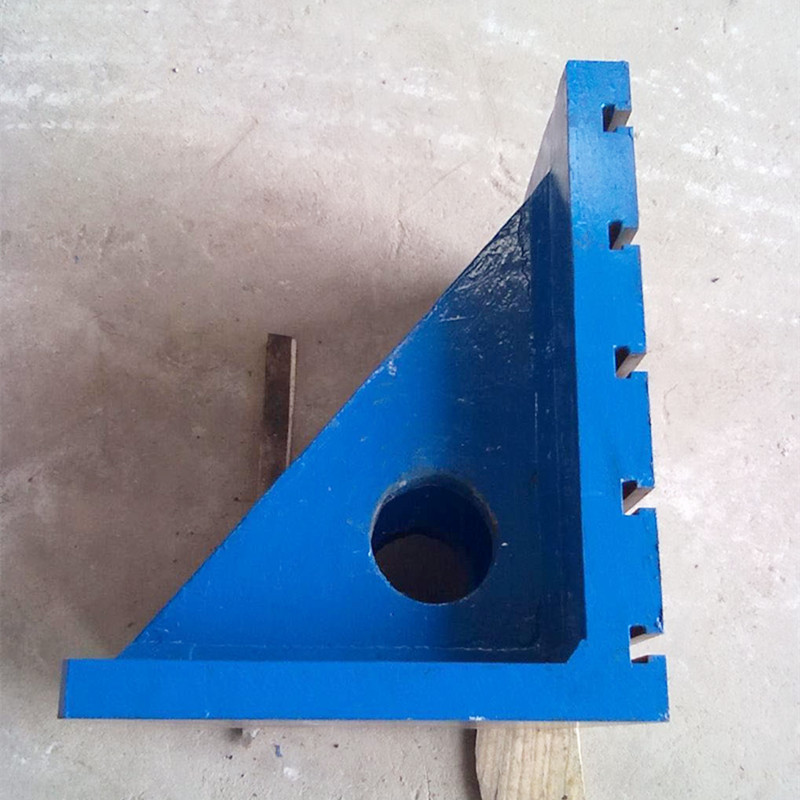

თუჯის კუთხის ფირფიტები

პროდუქტის პარამეტრი

Product code: Cast iron bent plate, T-groove cast iron bent plate, inspection cast iron bent plate

The advantages of cast iron bending plates are high precision, good wear resistance, and easy maintenance.

Cast iron bending plate specifications: 200 × 200~800 × 600 (millimeters) Precision: Level 0, Level 1, Level 2, Level 3.

Cast iron bent plates are manufactured according to JB6092-85 standard, made of HT200-HT300 material. The working surface adopts scraping and grinding technology, which is used for component inspection and clamping in mechanical processing.

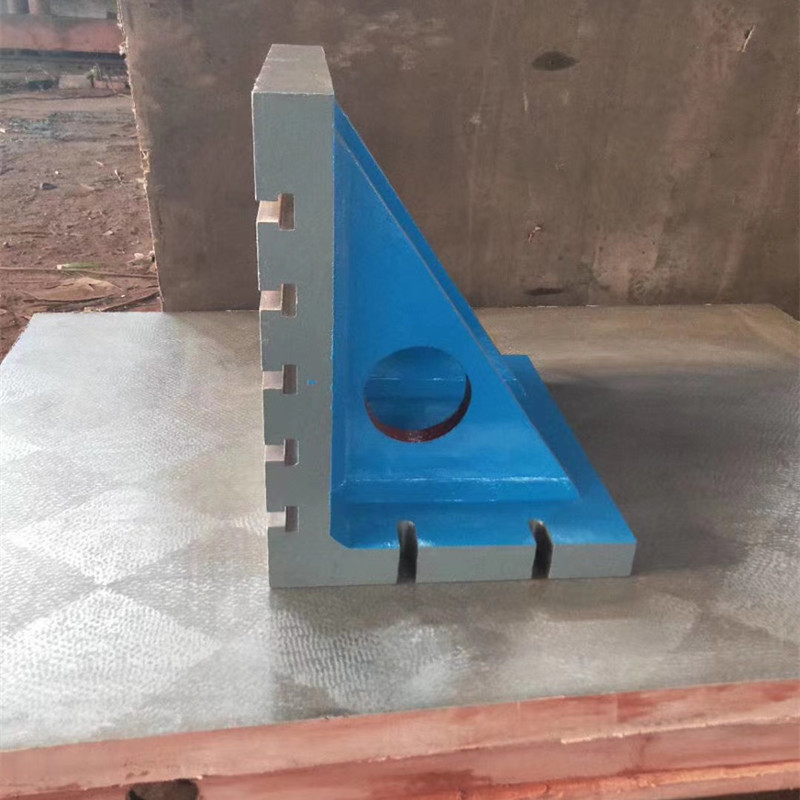

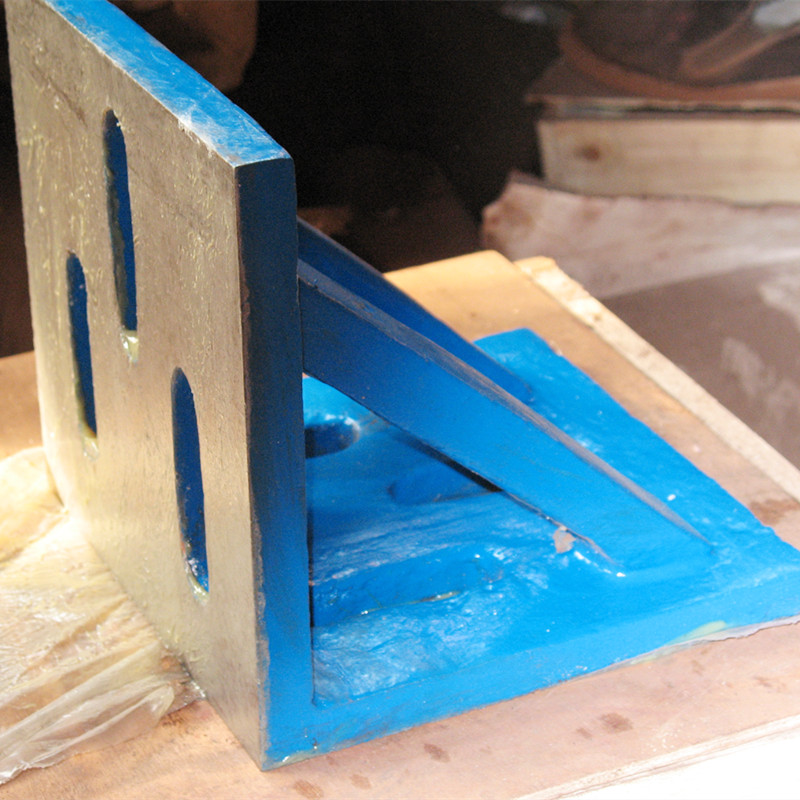

Application of cast iron bending plate: used for inspecting the 90 ° angle of workpieces, checking the mutual perpendicularity of related surfaces of components during equipment maintenance, and also commonly used for marking by fitters. It can also be commonly used for inspection, installation, and vertical surface inspection of machine tools, and can check the verticality of workpieces on cast iron flat plates. It is suitable for high-precision mechanical and instrument inspection and inspection of non verticality between machine tools.

წარმოშობის ადგილი: ჰებეი, ჩინეთი

გარანტია: 1 წელი

მორგებული მხარდაჭერა: OEM, ODM, OBM

ბრენდის სახელი: Storan

Model Number:2012

მასალა: მორგებულია

სიზუსტე: მორგებულია

ოპერაციის რეჟიმი: მორგებული

ნივთის წონა: მორგებულია

მოცულობა: მორგებულია

Product Name:Cast Iron Angle Plate

მასალა: HT200-300

Size:customized

Hardness Of Working Surface:HB160-240

Foundry Process:resin sand casting

Structure:customized

Painting:primer and face paint

Precision Grade:1-3

Working Temperature:(20±5) ℃

შეფუთვა: პლაივუდის ყუთი

ტყვიის დრო

|

რაოდენობა (ცალი) |

1 - 1200 |

> 1200 |

|

მიწოდების დრო (დღეები) |

30 |

მოსალაპარაკებლად |

Product Specifications

მასალა: HT200-300

Specification: customize

Hardness of the working surface: HB160-240

Surface treatment: scraping, ground finish or machined finish

Foundry process: resin sand casting

Painting: primer and face painting

Surface coating: working surface covered with pickling oil and non-working surface covered with anticorrosion paint

Working temperature: (20±5) ℃

სიზუსტის კლასი: 1-3

Packaging: plywood box

პროდუქტის პარამეტრი

|

No. |

Width X Length(mm) |

Straightness or Flatness of Working Surface |

Parallelism Between Both Working Surfaces |

||||

|

Precision Degree(μm) |

|||||||

|

1 |

2 |

3 |

1 |

2 |

3 |

||

|

1 |

500 × 45 |

6 |

12 |

|

9 |

18 |

|

|

2 |

750 × 50 |

8 |

15 |

|

12 |

25 |

|

|

3 |

1000 × 55 |

10 |

20 |

|

15 |

30 |

|

|

4 |

1200 × 60 |

12 |

24 |

|

18 |

36 |

|

|

5 |

1500 × 60 |

15 |

30 |

|

20 |

40 |

|

|

6 |

2000 × 80 |

20 |

40 |

80 |

27 |

54 |

|

|

7 |

2500 × 80 |

25 |

50 |

100 |

33 |

65 |

130 |

|

8 |

3000 × 100 |

|

60 |

120 |

|

78 |

156 |

Low-Maintenance Design of Cast Iron Angle Plates: HB160-240 Hardness for Longevity

In industrial fixturing, cast iron angle plates must endure heavy use without frequent upkeep. Storaen leverages HT200-HT300 gray cast iron (HB160-240) to create angle plate casting solutions that minimize maintenance—ideal for workshops where tool downtime is costly. Here’s how our design ensures durability with ease:

1. Hardness for Wear & Impact Resistance

Our cast iron box angle plate models (160–240HB) outlast softer materials by 2x:

Abrasion Resistance: Pearlitic microstructure withstands 10,000+ clamping cycles without losing 90° squareness (±5' tolerance), critical for milling/drilling fixtures where constant tool contact damages lower-hardness alternatives.

Impact Resilience: 200–300MPa tensile strength absorbs minor impacts, avoiding dents/cracks that plague aluminum plates and require frequent repairs.

2. Stress-Relieved Stability

A two-step process ensures lasting precision:

Resin Sand Casting: Uniform walls (15–30mm) and 550°C annealing eliminate 90% of casting stress, preventing warping. Maintains Class 2 flatness (≤0.02mm/m) over 600mm, stable across 10°C–40°C.

Durable Surface Finishes: Milled (Ra ≤3.2μm) resists coolant buildup; optional hand scraping (Ra ≤1.6μm) adds no extra maintenance—unlike peeling coatings on cheaper plates.

3. Corrosion & Friction Control

Low-maintenance features for harsh environments:

Natural Protection: Dense cast iron reduces rust by 50% vs. steel; 5μm pickling oil coating extends resistance in humid workshops.

Self-Lubricating Graphite: Reduces friction between plate and workpieces, eliminating the need for frequent oiling—common with other materials.

4. High-Demand Applications

Proven in tough scenarios:

Heavy Machinery Fixturing: 600x400mm cast iron angle plate supports 300kg engine blocks daily for 5+ years without degradation, saving $2,000+ in annual resurfacing costs.

Automated Inspection: Stable HB180 surface maintains 90° alignment (±10") in robotic CMM setups, cutting calibration frequency by 75% and boosting throughput.

5. Storaen’s Low-Maintenance Promise

Durable Design: From 200x200mm bench to 800x600mm industrial models, no fragile components or complex coatings.

Quality Assurance: Meets GB/T 6092-85/ISO 1101, backed by a 1-year warranty against hardness loss or drift.

Longevity Advantage: 3x service life of generic plates, lowering total cost of ownership for reliable production.

Choose Storaen’s cast iron angle plates for hassle-free precision. Our cast iron box angle plate solutions combine HB160-240 hardness, stress-free casting, and corrosion resistance to deliver long-lasting performance with minimal maintenance. Focus on your workflow—we’ll handle the durability.

Cast Iron Angle Plate Applications: Fixture Making & 90° Squareness Check

In precision manufacturing, cast iron angle plates are essential for stable fixturing and geometric accuracy, especially where 90° squareness is critical. Storaen’s angle plate casting solutions offer the rigidity and durability to excel in two key roles: fixture making and squareness inspection.

1. Fixture Making: Precision Positioning for Machining

Storaen’s cast iron angle plates create reliable bases for workpiece clamping:

Heavy-Duty Stability: Made from HT200-HT300 cast iron (160–240HB), they withstand 200 kg+ loads without deformation—ideal for CNC milling automotive transmission housings. A 400x300mm cast iron box angle plate ensures drilled holes maintain exact 90° alignment with mating surfaces, reducing fixture errors.

Modular T-Slot Design: Standard 14–24mm T-slots (±0.1mm tolerance) accept quick clamps and indicators, cutting setup time by 50% compared to custom steel fixtures. This versatility suits job shops handling engine mounts, valves, and robotic parts with a single 600x400mm plate.

2. 90° Squareness Check: Ensuring Mechanical Integrity

For critical perpendicularity verification:

CMM Calibration: Class 0 cast iron box angle plates (≤0.0005mm/m flatness) serve as reference standards for aerospace component inspection, like jet engine brackets, ensuring 90° angles within ±5" to prevent vibration fatigue.

Machine Tool Alignment: A 300x200mm cast iron angle plate confirms spindle verticality in lathes/mills to ISO 1101, reducing tool wear by 15% and improving surface finish (Ra ≤1.6μm) in heavy steel cuts.

3. Storaen’s Design Advantages for Industrial Needs

Vibration-Dampening Material: HT200-HT300 cast iron reduces measurement errors by 40% in noisy workshops, maintaining squareness during live machining.

Custom Solutions: Bespoke 800x600mm plates with reinforced ribs for stamping fixtures are delivered in 4–6 weeks, optimizing load distribution for heavy-duty use.

Quality Assurance: Every plate meets GB/T 6092-85/ISO 1101 via CMM testing, with a 1-year warranty against squareness drift for high-stakes applications.

4. Industry Impact: Efficiency & Accuracy

Automotive: A Tier 1 supplier uses our angle plate casting to fixture cylinder heads, achieving ±0.01mm perpendicularity and eliminating engine assembly rework.

Aerospace: Cast iron box angle plates ensure wing rib rivet holes align with fuselage frames, cutting aircraft assembly time by 30%.

Storaen’s cast iron angle plates empower precision in fixturing and squareness checks. Engineered for heavy loads and repeatable accuracy, our angle plate casting solutions reduce setup time, enhance tool life, and meet the strictest industrial standards, backed by a brand committed to manufacturing excellence.

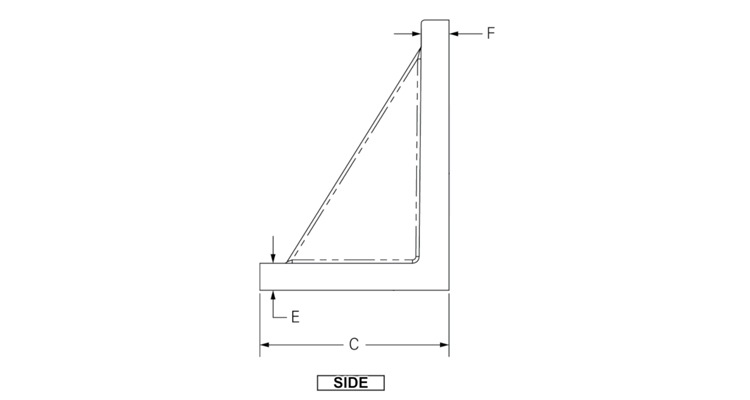

პროდუქტის დეტალური ნახაზი

დაკავშირებული პროდუქტები

დაკავშირებული სიახლეები

Thread Plug Gauge Requires Careful Handling

In the world of manufacturing and engineering, precision is non-negotiable—especially when it comes to threads, which are critical components in machinery, construction, and everyday products.

Surface plate calibration

In today's world, where precision and accuracy are crucial in various industries, the use of granite inspection tables and granite surface plates has become increasingly popular.

Ring Gauge Ensures Machining Accuracy

In the world of precision engineering, manufacturing, and quality control, accuracy is the cornerstone of reliability.