სექ . 16, 2024 01:38 Back to list

Spline Gauge - Precision Measurement Tools for Engineering Applications

Understanding Spline Gauge An Essential Tool in Precision Engineering

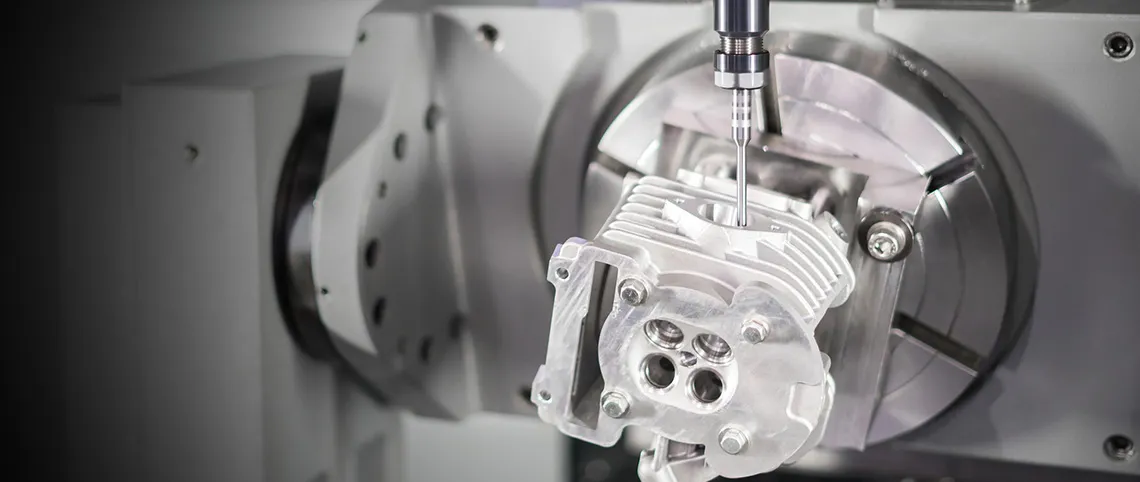

In the realm of precision engineering and manufacturing, the importance of accurately measuring and verifying dimensions cannot be overstated. Among the various tools available for this purpose, the spline gauge stands out as a vital instrument specifically designed to measure the profiles of splines—key components in mechanical systems that transfer torque between shafts.

A spline is a series of ridges or teeth on a shaft or hole that allows for a secure mechanical connection between components. Commonly found in automotive drive trains, aerospace applications, and industrial machines, splines must meet precise specifications to ensure proper fit and function. This is where the spline gauge comes into play.

What is a Spline Gauge?

A spline gauge is a specialized measuring tool used to assess the dimensional characteristics of splines, including their thickness, depth, and spacing. Typically made from high-strength materials such as hardened steel, spline gauges are designed to withstand wear and provide accurate measurements. They come in various shapes and configurations to accommodate different types of splines, including involute splines, parallel key splines, and more.

The design of the spline gauge allows for both direct measurement of the spline profile and the ability to check the dimensional tolerances specified in engineering drawings

. These gauges often incorporate features such as slots or notches that conform to the specific geometry of the spline, enabling quick and reliable checks.Importance of Spline Gauges

spline gauge

The use of spline gauges is critical in maintaining quality control in manufacturing processes. As splines are crucial for transferring power, any deviation from the specified dimensions can lead to improper engagement, excessive backlash, or even component failure. Thus, a spline gauge serves as an assurance that each part meets required tolerances before it is used in assembly.

Moreover, spline gauges are invaluable in the field of maintenance and repair. Technicians can use these gauges to determine whether a worn or damaged spline can be refurbished or needs replacement. This capability can lead to significant cost savings and extended machinery lifespan.

Choosing the Right Spline Gauge

When selecting a spline gauge, it is essential to consider the specific type of spline being measured and the precision requirements of the application. Different industries may have varying standards, so the gauge must be compatible with the relevant specifications. It is also advisable to choose a gauge with a robust construction that can endure repetitive use in a workshop environment.

Conclusion

In summary, the spline gauge is a quintessential tool for ensuring precision in the manufacturing and maintenance of spline applications. By accurately measuring the dimensions of splines, it helps maintain the integrity and functionality of mechanical systems. As technology continues to advance, developments in design and materials will likely yield even more effective gauges, further enhancing the ability to produce high-quality components in diverse industries. For engineers and technicians alike, understanding and utilizing spline gauges are essential for achieving excellence in precision engineering.

-

Precision Manufacturing with Advanced Spline Gauge DesignNewsJul.31,2025

-

Industrial-Grade Calibrated Pin Gauges for Exact MeasurementsNewsJul.31,2025

-

Industrial Filtration Systems Depend on Quality Filter DN50 SolutionsNewsJul.31,2025

-

High-Performance Gate Valve WholesaleNewsJul.31,2025

-

Granite Surface Plate The Ultimate Solution for Precision MeasurementNewsJul.31,2025

-

Granite Industrial Tools The Ultimate Guide for Bulk BuyersNewsJul.31,2025

Related PRODUCTS