ივნ . 27, 2025 11:22 სიაში დაბრუნება

Historical Evolution of Iron Surface Plates in Industrial Metrology

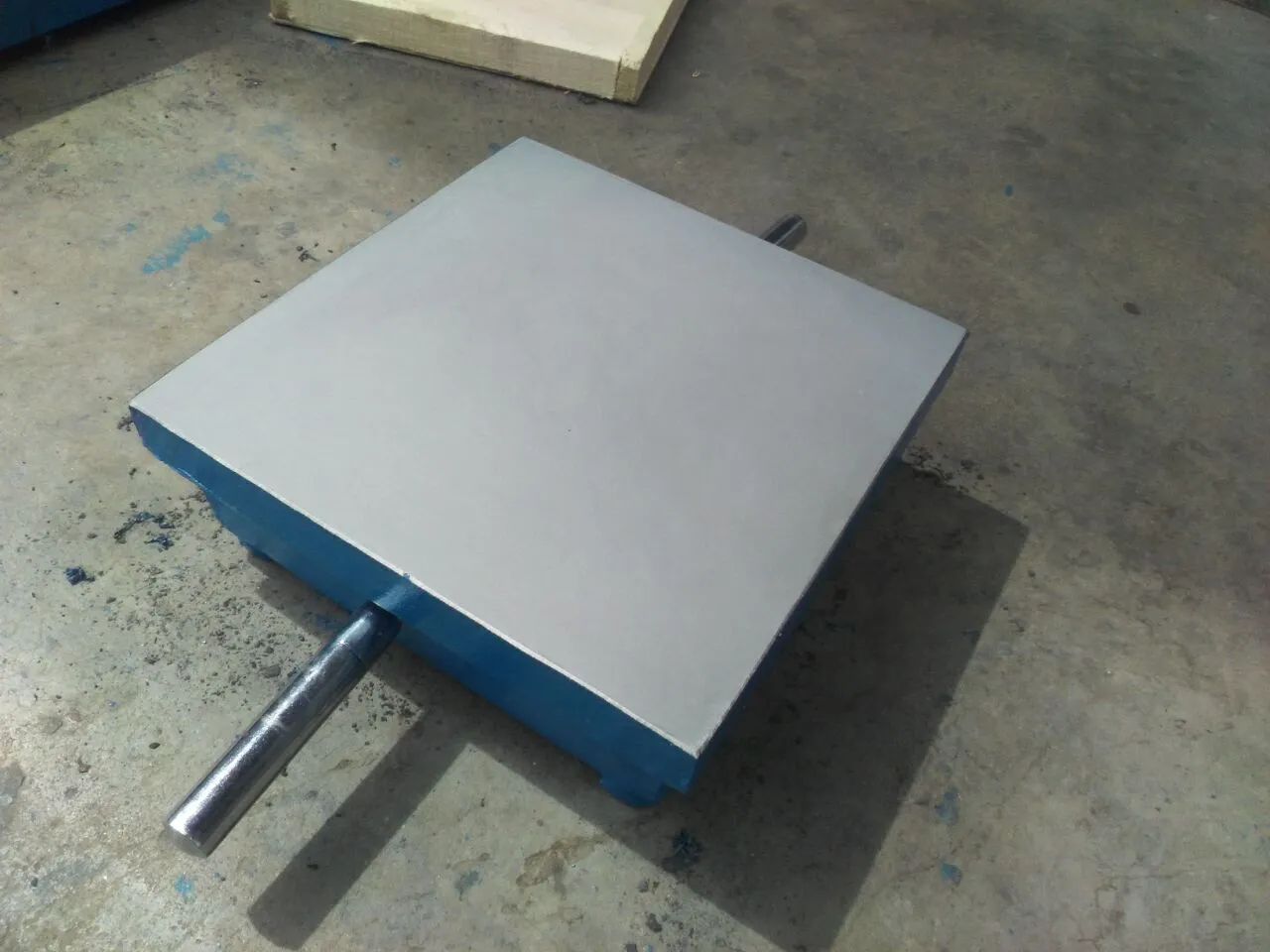

Industrial metrology, the science of precise measurement, has relied on robust and stable tools for centuries. Among these, iron surface plates and their variants—cast iron surface plates, cast iron lapping plates, and cast iron base plates—have played pivotal roles in ensuring accuracy across manufacturing, engineering, and quality control. This article traces their historical development, technological advancements, and enduring relevance in modern industry.

The Origins and Industrial Significance of Cast Iron Surface Plates

The use of cast iron surface plates dates back to the early Industrial Revolution, when the demand for standardized measurement tools surged. Cast iron, prized for its durability, vibration-damping properties, and resistance to deformation, became the material of choice for creating flat reference surfaces. By the mid-18th century, engineers recognized that cast iron surface plates could serve as foundational tools for layout work, inspection, and assembly processes.

Early designs were rudimentary, often hand-scraped to achieve near-flatness. However, the advent of machine tools in the 19th century allowed for more precise milling and grinding techniques. This period saw the standardization of cast iron surface plates in factories, where they became indispensable for calibrating gauges, checking part geometries, and ensuring interchangeability in mass production. Their thermal stability and ability to maintain flatness under load solidified their status as metrological cornerstones.

Precision Refinement: The Role of Cast Iron Lapping Plates in Metrology

As industrial processes grew more sophisticated, so did the need for ultra-precise surfaces. Enter cast iron lapping plates, specialized tools designed to achieve micron-level flatness through abrasive refinement. Unlike standard iron surface plates, lapping plates underwent a meticulous process of grinding with fine abrasives, such as diamond or aluminum oxide, to eliminate microscopic imperfections.

The development of cast iron lapping plates in the late 19th century revolutionized industries like optics and watchmaking, where sub-millimeter accuracy was critical. These plates enabled the production of master gauges and reference standards, ensuring consistency across global manufacturing networks. Today, cast iron lapping plates remain vital for calibrating high-precision instruments, thanks to their unmatched surface integrity and wear resistance.

Versatility and Adaptation: The Evolution of Iron Surface Plates

While cast iron surface plates dominated heavy industries, simpler iron surface plates found applications in smaller workshops and educational settings. Made from lower-grade iron alloys, these plates balanced affordability with sufficient accuracy for tasks like prototyping or basic inspection. Over time, advancements in material science improved their corrosion resistance and load-bearing capacity, broadening their utility.

The 20th century introduced modular designs, allowing iron surface plates to be reconfigured for complex assemblies. Manufacturers began offering plates with grid patterns, threaded holes, and custom coatings to meet diverse industrial needs. Despite competition from granite and ceramic alternatives, iron surface plates retained their niche due to their reparability and cost-effectiveness for large-scale operations.

Foundations of Stability: The Engineering Behind Cast Iron Base Plates

No discussion of industrial metrology is complete without cast iron base plates, the unsung heroes supporting heavy machinery and measurement systems. These plates, often several inches thick, provide a vibration-damped, thermally stable foundation for precision equipment like coordinate measuring machines (CMMs) or optical comparators.

The design philosophy behind cast iron base plates emerged in the early 20th century, as factories sought to minimize environmental interference in measurements. By integrating internal ribbing and stress-relieved casting techniques, engineers enhanced their rigidity and longevity. Modern cast iron base plates are often paired with leveling systems and shock-absorbing mounts, ensuring zero deflection even in dynamic industrial environments.

FAQs About Iron Surface Plates in Industrial Metrology

What distinguishes a cast iron surface plate from a granite surface plate?

A cast iron surface plate offers superior vibration damping and impact resistance compared to granite. It is also repairable through scraping or grinding, making it ideal for high-wear environments. Granite, while chemically inert, is brittle and less adaptable to heavy machinery.

How often should a cast iron lapping plate be recalibrated?

Recalibration intervals depend on usage intensity. For daily industrial use, annual recalibration is recommended. However, visual inspections for scratches or wear should be conducted monthly to maintain accuracy.

Can an iron surface plate be used outdoors?

While iron surface plates are durable, prolonged exposure to moisture can cause rust. For outdoor applications, plates with corrosion-resistant coatings or regular maintenance schedules are advised.

What factors determine the thickness of a cast iron base plate?

Thickness is dictated by load capacity and stability requirements. Heavy machinery may require base plates exceeding 6 inches, while lighter setups function well with 3–4-inch designs.

Are cast iron surface plates suitable for high-temperature environments?

Cast iron withstands moderate thermal fluctuations, but extreme heat can warp the surface. In such cases, thermally stabilized variants or supplementary cooling systems are recommended.

From their inception during the Industrial Revolution to their modern-day iterations, iron surface plates, cast iron lapping plates, and cast iron base plates have been indispensable to metrology. Their evolution mirrors advancements in manufacturing, materials science, and precision engineering. As industries continue to prioritize accuracy and efficiency, these tools will remain foundational to quality assurance and innovation. Manufacturers producing these plates in large quantities ensure their accessibility, enabling industries worldwide to uphold the highest standards of measurement.

-

Why Metric Trapezoidal Thread is Ideal for Precision Motion ControlსიახლეებიAug.05,2025

-

The Unique Properties of a Block of Granite for Industrial UseსიახლეებიAug.05,2025

-

The Role of Flanged Y Strainers in Preventing Pipeline ClogsსიახლეებიAug.05,2025

-

The Importance of Regular Calibration for Master Ring GagesსიახლეებიAug.05,2025

-

How a Cast Iron Surface Table Enhances Accuracy in ManufacturingსიახლეებიAug.05,2025

-

Comparing Different Check Valve Types for Optimal Flow ControlსიახლეებიAug.05,2025

Მსგავსი პროდუქტები