ოქტ . 10, 2024 00:41 Back to list

granite industrial tools

The Importance of Granite Industrial Tools in Modern Manufacturing

Granite has long been recognized for its durability, beauty, and versatility, making it a favored material in various industries, from construction and architecture to manufacturing and tooling. Within the realm of industrial applications, granite industrial tools play a critical role in enhancing precision, quality, and efficiency. This article delves into the significance of granite tools, their advantages, applications, and the reasons why they are indispensable in modern manufacturing.

What Are Granite Industrial Tools?

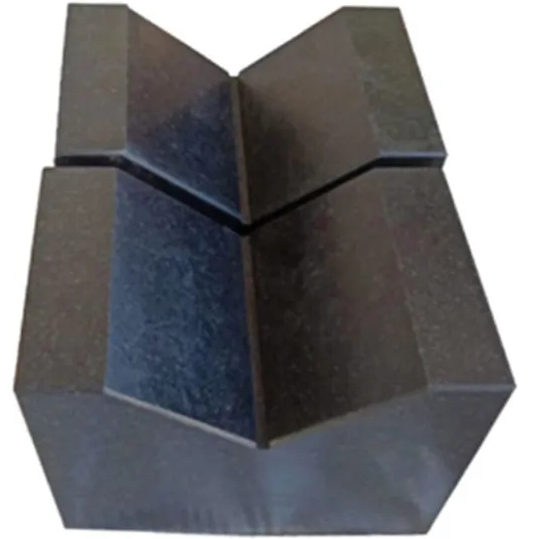

Granite industrial tools are precision instruments typically made from natural granite. These tools are often used in the machining and manufacturing industries, particularly for applications that require high levels of accuracy and stability. Common granite tools include surface plates, inspection tables, gauge blocks, and leveling instruments.

The inherent properties of granite—its hardness, resistance to wear, and stability—make it an ideal material for these tools. Unlike metal, granite does not warp or change dimensions due to temperature fluctuations, ensuring that measurements remain consistent and accurate over time.

Advantages of Granite Tools

1. Precision and Accuracy One of the primary advantages of granite tools is their exceptional flatness and stability. For industries that require precise measurements, such as aerospace, automotive, and electronics, granite tools ensure that components are produced to the exact specifications needed. As granite does not expand or contract like many metals, it maintains its precision under varying environmental conditions.

2. Durability Granite is renowned for its toughness and longevity. Tools made from granite can withstand heavy use and are resistant to wear and scratching, making them ideal for rigorous manufacturing environments. This durability reduces the need for frequent replacements, resulting in cost savings for companies.

3. Ease of Maintenance Granite industrial tools require minimal maintenance. They can be easily cleaned and do not corrode or rust like metal tools. A simple wipe with a damp cloth typically suffices to keep them in optimal condition, allowing manufacturers to focus on production without worrying about tool degradation.

granite industrial tools

4. Vibration Damping The mass and density of granite provide excellent vibration dampening properties. This is crucial in machining operations where vibrations can lead to inaccuracies and affect the quality of the finished product. By using granite tools, manufacturers can achieve better surface finishes and enhance the life of their machinery.

Applications of Granite Industrial Tools

Granite tools are employed across various sectors

- Quality Control and Inspection In automated and manual inspection processes, granite surface plates serve as the foundation for measuring and checking the dimensions of manufactured parts. Their flatness ensures that measurements taken are reliable.

- Machining Setups Machine operators often use granite tables for setting up tooling and fixtures due to their stability. This helps in achieving higher repeatability and accuracy in machining operations.

- Calibration Gauge blocks made from granite are used to calibrate and align measuring instruments, ensuring that they are operating accurately. This is crucial in maintaining quality standards in production processes.

- Metrology Granite tools are indispensable in metrology laboratories, where precise measurements are crucial for development and quality assurance. The use of granite ensures that measurement reliability is upheld.

Conclusion

In conclusion, granite industrial tools are essential assets in the manufacturing sector, driven by their unmatched precision, durability, and maintenance ease. As industries continue to evolve towards higher standards of accuracy and efficiency, the role of granite in tooling and measuring will only become more significant. Investing in granite industrial tools not only enhances production capabilities but also solidifies a company's reputation for quality and reliability in a competitive marketplace. As technology advances and manufacturing processes become more sophisticated, granite tools will continue to stand the test of time, adapting to the needs of future innovations while maintaining their foundational role in precision engineering.

-

Why Metric Trapezoidal Thread is Ideal for Precision Motion ControlNewsAug.05,2025

-

The Unique Properties of a Block of Granite for Industrial UseNewsAug.05,2025

-

The Role of Flanged Y Strainers in Preventing Pipeline ClogsNewsAug.05,2025

-

The Importance of Regular Calibration for Master Ring GagesNewsAug.05,2025

-

How a Cast Iron Surface Table Enhances Accuracy in ManufacturingNewsAug.05,2025

-

Comparing Different Check Valve Types for Optimal Flow ControlNewsAug.05,2025

Related PRODUCTS