ნოე . 12, 2024 07:59 Back to list

flanged check valve

Understanding Flanged Check Valves An Overview

Flanged check valves are essential components in various fluid handling systems, ensuring the proper direction of flow while preventing backflow. Commonly used in industries such as water and wastewater management, oil and gas, and chemical processing, these valves play a crucial role in maintaining system integrity and efficiency.

What is a Flanged Check Valve?

A flanged check valve is a type of valve that automatically prevents backflow in a piping system. Its design features flanges—flat surfaces or extensions that are fitted to the ends of the valve—allowing it to be easily connected to other related piping components. The flanges are typically bolted to the corresponding flanges of the piping, ensuring a secure and leak-free connection.

One of the defining characteristics of check valves is their one-way flow mechanism. This means they allow fluid to flow in only one direction and will close automatically when there is a reverse flow, protecting the system from potential damage and preserving the efficiency of processes.

Components of a Flanged Check Valve

Flanged check valves consist of several key components, each playing a vital role in the valve's operation

1. Body The main structure of the valve, usually made from materials such as cast iron, stainless steel, or PVC, depending on the application and medium being handled.

2. Disc The component that opens to allow flow and closes to prevent backflow. It is often spring-loaded or weight-actuated to ensure quick closure when reverse flow is detected.

3. Flanges These are integral to the installation process; they are typically designed to meet specific standards like ANSI, ASME, or DIN, allowing compatibility with various piping systems.

4. Seal Often made from rubber or other polymer materials, the seal is essential for preventing leaks when the valve is closed.

5. Spring In spring-loaded flanged check valves, a spring assists in the closing mechanism, efficiently shutting the valve when backflow is sensed.

Advantages of Flanged Check Valves

flanged check valve

Flanged check valves offer several advantages that make them suitable for a wide range of applications

- Easy Installation The flanged design allows for straightforward installation and maintenance, as the valve can be easily bolted onto the piping system without complex fittings.

- Reliable Performance These valves are designed to operate automatically, ensuring that they react promptly to changes in flow direction, thereby protecting equipment from potential damage.

- Durable Construction Most flanged check valves are constructed from robust materials that can withstand high pressures and temperatures, making them suitable for harsh environments.

- Versality They can handle various media, including liquids, gases, and slurries, making them applicable in many sectors.

Applications of Flanged Check Valves

Flanged check valves are used in a plethora of applications

1. Water and Wastewater Treatment In municipal systems, they prevent the backflow of contaminated water into clean water supplies and ensure efficient drainage.

2. Pumping Stations They protect pumps by preventing backflow, which can result in cavitation and potential damage to the pump internals.

3. Oil and Gas Industry Flanged check valves are used to prevent backflow in pipelines carrying crude oil, natural gas, and other petroleum products, ensuring safety and efficiency.

4. Chemical Processing These valves help manage the flow of corrosive chemicals, ensuring containment and mitigating leaks.

Conclusion

Flanged check valves are critical components in various fluid control systems. Their ability to prevent backflow, ease of installation, and durable construction make them indispensable in many industrial applications. Understanding the features and benefits of flanged check valves can enhance system design, improve efficiency, and ensure the longevity of piping infrastructure. With ongoing innovations in valve technology, the reliability and performance of flanged check valves will continue to evolve, adapting to the changing needs of industries worldwide. As facilities look to optimize their operations, choosing the right check valve becomes paramount in maintaining operational integrity and efficiency.

-

Why Metric Trapezoidal Thread is Ideal for Precision Motion ControlNewsAug.05,2025

-

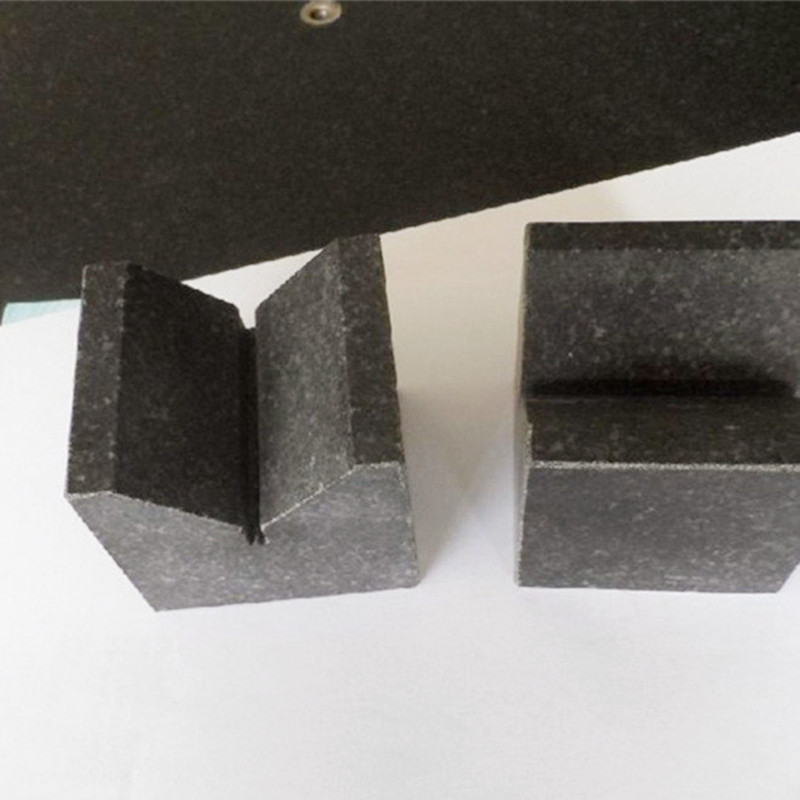

The Unique Properties of a Block of Granite for Industrial UseNewsAug.05,2025

-

The Role of Flanged Y Strainers in Preventing Pipeline ClogsNewsAug.05,2025

-

The Importance of Regular Calibration for Master Ring GagesNewsAug.05,2025

-

How a Cast Iron Surface Table Enhances Accuracy in ManufacturingNewsAug.05,2025

-

Comparing Different Check Valve Types for Optimal Flow ControlNewsAug.05,2025

Related PRODUCTS