ნოე . 30, 2024 10:44 Back to list

Types of Check Valves and Their Applications in Fluid Systems

Understanding Check Valve Types

Check valves are essential components in many fluid systems, ensuring that fluids flow in one direction while preventing backflow. This functionality is particularly important in various industrial applications, plumbing systems, and other engineering systems. There are several types of check valves, each designed for specific applications and operational requirements. In this article, we will explore the main types of check valves, their features, advantages, and typical uses.

1. Swing Check Valve

The swing check valve is one of the most common types of check valves. It uses a hinged disk that swings open to allow fluid to pass through in the forward direction. When the fluid flow reverses, the disk swings back against the seat, preventing backflow. Swing check valves are favored for their simple design and low pressure drop. They are commonly used in water and wastewater treatment, HVAC systems, and other applications where a secure seal and minimal flow resistance are required.

2. Lift Check Valve

Lift check valves function similarly to swing check valves, but instead of a disk that swings open, they use a movable disk (or piston) that lifts off its seat to allow flow. When the flow direction reverses, the disk drops back onto the seat to prevent backflow. Lift check valves are often used in high-pressure applications and are less prone to chattering—a common issue in swing check valves. However, they can be more susceptible to wear over time, especially in applications with dirty fluids.

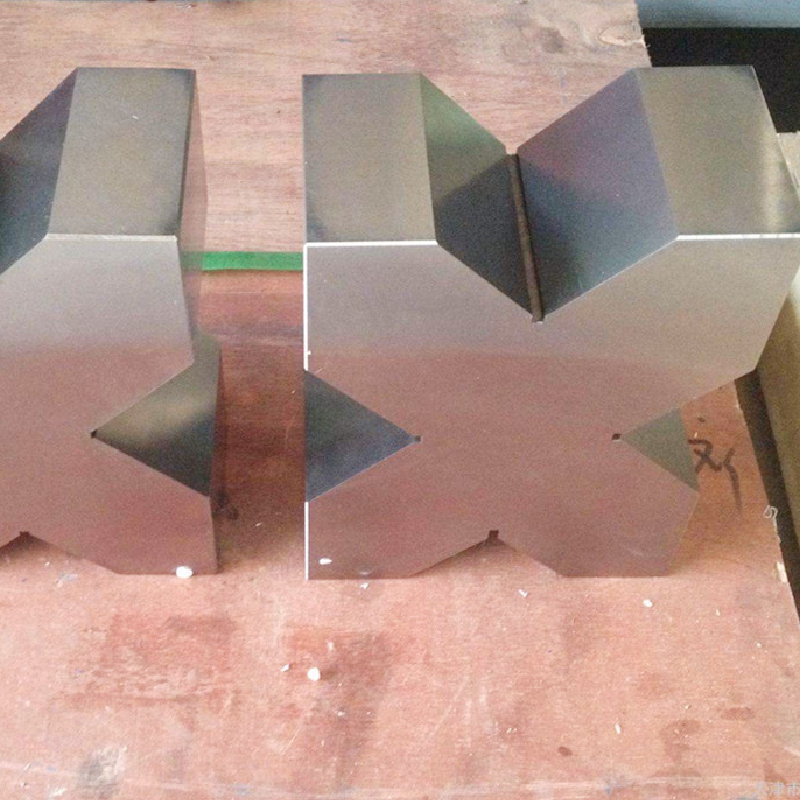

check valve types

Ball check valves utilize a spherical ball that seats against a valve opening. When fluid flows in the forward direction, the ball is lifted off the seat, allowing fluid to pass. If the flow reverses, the ball is pushed back into its seat, effectively blocking the backflow. These valves are compact and can handle high-pressure applications. Ball check valves are often seen in pumping systems, sewage systems, and irrigation systems due to their reliability and effectiveness.

4. Diaphragm Check Valve

Diaphragm check valves use a flexible diaphragm to control flow. The diaphragm moves up and down in response to fluid pressure changes, allowing flow in one direction while sealing off the other. These valves are particularly useful for handling fluids that may contain solid particles, as the diaphragm minimizes wear and tear on internal components. Diaphragm check valves are commonly used in pharmaceutical, food processing, and corrosive fluid applications.

5. Tilting Disc Check Valve

The tilting disc check valve features a disc that tilts to allow flow and returns to its seat to prevent backflow. This design allows for a more efficient flow profile and can handle high flow rates with low pressure drops. Tilting disc check valves are often employed in power plants, oil refineries, and large pumping stations where space constraints and performance are critical factors.

Conclusion

Selecting the right type of check valve is crucial for the efficiency and reliability of fluid systems. Each type of check valve has its features and advantages, making it suitable for different applications based on factors such as pressure, flow rate, and fluid composition. Understanding the mechanics and applications of swing check valves, lift check valves, ball check valves, diaphragm check valves, and tilting disc check valves is essential for engineers and operators when designing and maintaining fluid systems. As industries continue to evolve, the demand for reliable and efficient check valves remains integral to safe and effective fluid management.

-

Why Metric Trapezoidal Thread is Ideal for Precision Motion ControlNewsAug.05,2025

-

The Unique Properties of a Block of Granite for Industrial UseNewsAug.05,2025

-

The Role of Flanged Y Strainers in Preventing Pipeline ClogsNewsAug.05,2025

-

The Importance of Regular Calibration for Master Ring GagesNewsAug.05,2025

-

How a Cast Iron Surface Table Enhances Accuracy in ManufacturingNewsAug.05,2025

-

Comparing Different Check Valve Types for Optimal Flow ControlNewsAug.05,2025

Related PRODUCTS