ნოე . 10, 2024 04:10 Back to list

10 Inch Check Valve for Reliable Fluid Control Solutions and Applications

Understanding the 10% 20 Inch Check Valve

When it comes to managing fluid flow in industrial and commercial applications, check valves serve a critical role. Among the various types, the 10% 20 inch check valve stands out for its size and functionality. Designed to prevent backflow, these valves ensure that fluid flows in one direction while simultaneously protecting equipment and maintaining system efficiency.

What is a Check Valve?

A check valve, also known as a non-return valve, is a device that allows fluid (liquid or gas) to flow through it in one direction only. The primary function of a check valve is to prevent reverse flow, which can cause significant problems in pipelines and related systems. The design typically includes a disc that opens when fluid flows in the intended direction and closes when the fluid flows backward.

The 10% Specification

The term 10% in the name denotes a specific pressure drop or flow requirement that the valve meets under standard testing conditions. It suggests that the valve should effectively handle a certain flow rate while maintaining a minimal pressure drop. This specification ensures that the check valve operates efficiently within the designated system parameters, contributing to optimal overall system performance.

Importance of the 20 Inch Size

The 20 inch designation refers to the diameter of the valve's opening, which can accommodate significant flow volumes. In large-scale industrial applications, such as water treatment plants, oil and gas facilities, and chemical processing units, the ability to manage large amounts of fluid is crucial. A 20-inch check valve can handle substantial flow rates, making it suitable for high-capacity systems where back pressure could cause severe operational challenges.

Applications of 10% 20 Inch Check Valves

Given their robust design and size, 10% 20 inch check valves are used across various industries

10 inch check valve

2. Oil and Gas In pipeline systems transporting crude oil or natural gas, these valves help maintain flow direction, safeguarding equipment from potential damage.

3. Chemical Processing Within chemical plants, backflow can lead to hazardous situations. A check valve can mitigate risks by securing the flow direction of corrosive materials.

4. HVAC Systems In heating and cooling systems, check valves ensure that fluids only flow to designated areas, preventing inefficiencies and equipment damage.

Benefits of the 10% 20 Inch Check Valve

1. Reliability With a robust construction and functional design, these valves prevent leaks and reduce the risk of system failures.

2. Efficiency By maintaining a 10% pressure drop specification, these check valves enhance the system’s efficiency, ensuring that operational costs remain low.

3. Durability Typically made from industrial-grade materials, 10% 20 inch check valves can withstand harsh environmental conditions, making them suitable for demanding applications.

4. Maintenance Many modern check valves are designed for easy maintenance and inspection, ensuring that any potential issues can be addressed quickly without major disruptions to operation.

Conclusion

In conclusion, a 10% 20 inch check valve is an essential component in many industrial systems. Its design allows for specific flow management while preventing backflow, making it invaluable in various applications such as water treatment, oil and gas, and chemical processing. Understanding the significance of these valves helps in ensuring the reliability and efficiency of fluid management systems, ultimately contributing to smoother operations and reduced costs. As industries continue to evolve and demand more efficiency, the role of check valves will undoubtedly remain critical in fluid dynamics.

-

Y Type Strainer Maintains System Efficiency Long TermNewsJul.15,2025

-

Valve Selection Guide for Industrial ApplicationsNewsJul.15,2025

-

Steel Fab Table Provides Durable Work Surface for WeldingNewsJul.15,2025

-

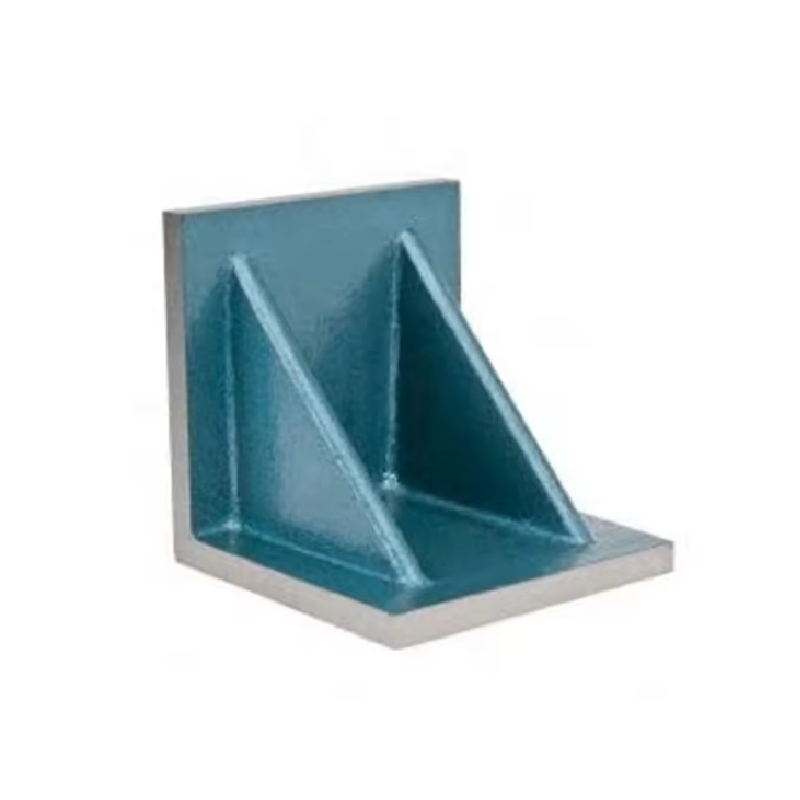

Pad Iron Provides Stable Support for Heavy MachineryNewsJul.15,2025

-

One Inch Check Valve Fits Standard Plumbing SystemsNewsJul.15,2025

-

Measuring Micrometer Ensures Precise Dimensional AccuracyNewsJul.15,2025

Related PRODUCTS