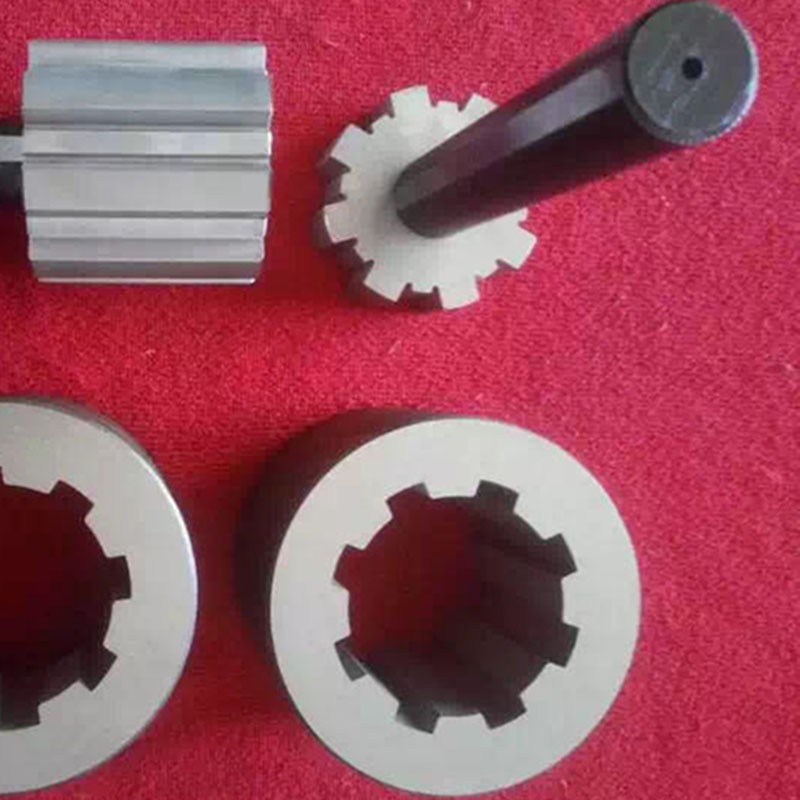

Spline Ring Gauge

Product Description

Our company can customise the nominal diameter 0.8mm-300mm metric (M), American (UN , UNC, UNF, UNEF, UNS, NPSC, NPSM, NPSH, NPSF, NPSI, NPSL, NH), British (BSW, BSF), Japanese standard PT, German standard RP (DIN2999), G-tube buckles, square buckles (Rectangle), R buckles ( Rd DIN405), serrated, trapezoidal (Tr, ACME, STUB ACME), gas cylinder (PZ, W), taper (NPT, NPTF, Z, BKG, R, RB, Rc, RP, PT, ZG, WKG, BSPT, ANPT, PTF, etc.), pipe thread gauges (G, PF, PS, BSP, BSPP, etc.), special for sewing machines (SM), ST wire thread gauge, bicycle (battery car) special thread gauge (B, BC), electrical appliances special thread (1BA, 2BA, 3BA, 4BA, 5BA, etc.), valve thread (5V1, 8V1, etc.) 80 ° thread gauges (Pg7, Pg9, Pg11, Pg13.5, Pg16, Pg21, Pg29, Pg36 Pg42, Pg48), API standard gages, API oil pipe thread gages, API taper gages, sucker rod thread gages (CYG13-10, CYG16-10, CYG19-10, CYG22-10, CYG25-10, CYG29-10, KGG32-10, KGG36-10, KGG40-10), Oil pipe thread gauge (LP, TBG, UP TBG, CSG, LCSG, NC).

Why Choose Strmachinery Spline Gauge Manufacturer

When it comes to precision engineering, the choice of tools and measuring devices is critical. Among these, the spline ring gauge stands out as an essential instrument for ensuring dimensional accuracy in spline applications. Strmachinery, a leading spline gauge manufacturer, offers advanced solutions tailored to meet industry-specific requirements, making them the ideal choice for professionals seeking reliability and quality.

One of the primary reasons for choosing Storaen is its exceptional spline gauge design. Storaen employs cutting-edge technology and innovative engineering techniques to create spline gauges that are not only robust but also highly precise. Their design ensures compatibility with various spline profiles, allowing for accurate measurement across a spectrum of applications. With Strmachinery’s gauges, engineers can expect superior performance, reducing the risk of errors that can lead to costly production setbacks.

In addition to their state-of-the-art designs, Storaen adheres strictly to spline gauge standards. Compliance with industry standards is critical for maintaining quality and trust, and Storaen recognizes this necessity. Their spline gauges are engineered to meet rigorous specifications, ensuring that each product delivers consistent results. By choosing a manufacturer that prioritizes standardization, clients can be confident that they are investing in tools that uphold the highest levels of precision and reliability.

Moreover, Storaen’s commitment to customer satisfaction sets them apart from competitors. With an extensive range of options and the ability to customize designs based on specific needs, they provide exceptional support throughout the purchasing process. This dedication not only enhances the user experience but also establishes them as a trusted partner in precision engineering.

In conclusion, if you are in the market for a quality spline ring gauge, look no further than Strmachinery. With their superior spline gauge design and unwavering adherence to spline gauge standards, they are the go-to manufacturer for professionals who value precision and reliability in their engineering projects. Choose Strmachinery and elevate your measurement accuracy today.

The Advantages of Using Spline Ring Gauges in Precision Measurement

In the realm of precision measurement and manufacturing, spline ring gauges have emerged as essential tools for ensuring accuracy and quality. These specialized gauges are designed to measure the tooth profile of spline shafts, providing manufacturers with a reliable means of verifying specifications and tolerances. In this blog post, we will explore the advantages of using spline ring gauges, highlighting their importance in various industrial applications.

Firstly, one of the key advantages of spline ring gauges is their ability to deliver high accuracy. When measuring the dimensions of spline profiles, precision is paramount. Spline ring gauges are manufactured to stringent standards, allowing for minimal tolerances. This high degree of accuracy reduces the risk of defects and reworks, ultimately leading to enhanced product quality.

Another notable benefit of spline ring gauges is their efficiency in gauging operations. They offer a quick and straightforward means of inspection, streamlining the quality control process. Unlike traditional measurement methods that may require intricate setups and calculations, spline ring gauges provide immediate results, which can significantly speed up production times. This efficiency is particularly valuable in high-volume manufacturing environments where time is of the essence.

Moreover, spline ring gauges contribute to improved consistency in measurements. Regular use of these gauges helps establish a standard across the production line, reducing variability caused by manual measurements. This consistency is crucial for manufacturers that prioritize uniformity, as it promotes better assembly and functionality of parts, especially in critical applications such as automotive and aerospace engineering.

In addition to their measurement capabilities, spline ring gauges also enhance the reliability of quality assurance processes. By implementing these gauges, manufacturers can quickly identify any deviations from specified tolerances, allowing for prompt corrective actions. This proactive approach to quality assurance can help avoid costly production delays and potential failures.

Product Detail Drawing

On-site pictures

Related PRODUCTS

RELATED NEWS

Thread Plug Gauge Requires Careful Handling

In the world of manufacturing and engineering, precision is non-negotiable—especially when it comes to threads, which are critical components in machinery, construction, and everyday products.

Surface plate calibration

In today's world, where precision and accuracy are crucial in various industries, the use of granite inspection tables and granite surface plates has become increasingly popular.

Ring Gauge Ensures Machining Accuracy

In the world of precision engineering, manufacturing, and quality control, accuracy is the cornerstone of reliability.