Jul . 29, 2025 10:10 Bali menyang dhaptar

Surface plate calibration

In today's world, where precision and accuracy are crucial in various industries, the use of granite inspection tables and granite surface plates has become increasingly popular. These tools offer unparalleled precision and reliability, making them indispensable in industries such as manufacturing, construction, and laboratories. From ensuring parts meet strict tolerances to serving as stable bases for measurement tools, granite inspection table, granite surface plate for sale, and surface plate play vital roles in maintaining quality standards. In this article, we will explore their key features, applications, maintenance, and frequently asked questions, providing a comprehensive guide to these essential precision tools.

Key Features of Granite Inspection Table in Precision Measurement

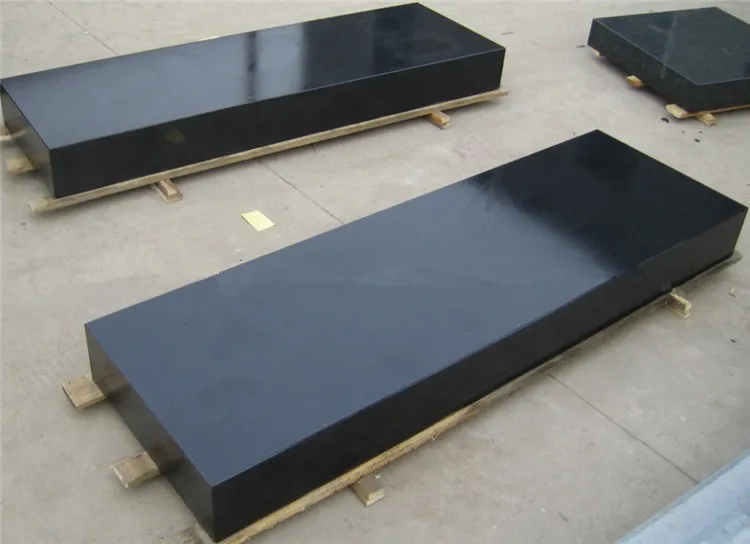

Granite inspection table stands as a cornerstone of precision measurement, valued for its unique material properties that make it ideal for high-accuracy tasks. Crafted from high-quality granite—often black granite or gray granite—these tables are engineered to deliver exceptional flatness, stability, and durability, setting them apart from other surface options.

One of the defining features of a granite inspection table is its superior flatness. Granite, formed over millions of years, has a dense, homogeneous structure that resists warping or deformation, even under temperature changes or heavy loads. This stability ensures that measurements taken on the table are consistent, as the surface remains true over time. Additionally, granite is non-magnetic, non-conductive, and resistant to corrosion, making it suitable for use with sensitive instruments like dial gauges, micrometers, or coordinate measuring machines that could be affected by magnetic interference.

Granite inspection table also boasts low porosity, which means it resists absorption of liquids or oils—critical for maintaining a clean surface free from stains or contamination. Its smooth, polished finish minimizes friction, allowing tools to glide easily during measurements without scratching the surface. These features combined make granite inspection table an essential tool in metrology labs, manufacturing facilities, and quality control departments where precision is non-negotiable.

Why Granite Surface Plate for Sale is a Top Choice for Industries

Granite surface plate for sale has become a preferred option for industries seeking reliable, high-performance surface solutions for inspection, tool setup, and manufacturing processes. These plates, available for purchase in various sizes and specifications, cater to diverse industrial needs while upholding the quality standards that granite is known for.

One of the primary reasons granite surface plate for sale is in high demand is its adaptability to different applications. Whether for small-scale workshops or large manufacturing plants, suppliers offer plates in sizes ranging from compact bench top models to large floor-mounted units, ensuring there’s a fit for every workspace. Many granite surface plate for sale options also come with customization features, such as drilled holes for fixture mounting or specialized finishes for specific measurement tasks, enhancing their versatility.

Beyond availability, granite surface plate for sale delivers long-term value due to granite’s inherent durability. Unlike metal or wooden surfaces that may wear, dent, or warp over time, granite surface plates resist wear from repeated use, maintaining their flatness and precision for years. This longevity reduces replacement costs, making them a cost-effective investment for businesses. For industries like aerospace, automotive, and engineering, where consistent quality control is critical, granite surface plate for sale provides the reliability needed to meet strict regulatory and operational standards.

The Versatile Applications of Surface Plate Across Sectors

Surface plate is a versatile tool with applications spanning multiple industries, serving as a reference surface for precision measurement, inspection, and tool calibration. While granite is a common material for surface plates, the term encompasses all flat, stable surfaces designed to ensure accuracy in various tasks, making it indispensable across sectors.

In manufacturing, surface plate is used to inspect parts for dimensional accuracy. Workers place components on the plate and use tools like height gauges or dial indicators to measure deviations from specifications, ensuring parts fit together correctly in final assemblies. In toolrooms, surface plate serves as a stable base for setting up machinery, such as lathes or milling machines, ensuring tools are aligned precisely to avoid errors in production.

Aerospace and defense industries rely heavily on surface plate for inspecting critical components like engine parts or aircraft fittings, where even minor discrepancies can compromise safety. Metrology labs use high-precision surface plates as reference standards for calibrating measuring instruments, ensuring that tools themselves are accurate. Beyond industrial settings, surface plate finds use in educational institutions for training students in precision measurement techniques, highlighting its role in fostering skills for future engineers and technicians. Its adaptability to diverse tasks solidifies surface plate as a foundational tool in any field requiring accuracy.

How to Maintain and Care for Granite Inspection Table for Longevity

Proper maintenance is key to preserving the precision and lifespan of a granite inspection table. While granite is durable, neglect can lead to scratches, stains, or loss of flatness, compromising its effectiveness. By following these simple care practices, users can ensure their granite inspection table remains reliable for years:

- Regular Cleaning: Wipe the surface daily with a soft, lint-free cloth to remove dust, debris, or fingerprints. For tougher stains, use a mild detergent mixed with water, applied with a non-abrasive sponge. Avoid harsh chemicals (e.g., acids, solvents) that can etch or discolor the granite.

- Avoid Impact and Abrasion: Prevent dropping heavy objects or using sharp tools directly on the table, as this can cause chips or scratches. Use protective pads or mats when placing heavy components or tools.

- Control Environment: Store the granite inspection tablein a temperature-stable area, away from direct sunlight, heaters, or air conditioners. Extreme temperature changes can cause minor expansion or contraction, affecting flatness over time.

- Periodic Calibration: Even with careful use, have the table’s flatness checked periodically by a professional. Calibration ensures that any minor deviations are identified and corrected, maintaining measurement accuracy.

- Cover When Not in Use: Use a dust cover or sheet when the table is not in use to protect it from dust, spills, or accidental damage.

By incorporating these practices into regular maintenance routines, users can maximize the longevity and performance of their granite inspection table, ensuring it remains a trusted tool for precision measurement.

FAQS about Granite Inspection Table, Granite Surface Plate for Sale, and Surface Plate

What makes granite inspection table superior to metal surface tables for precision work?

Granite inspection table outperforms metal tables due to granite’s inherent properties: it has low thermal expansion, meaning it remains stable across temperature changes, ensuring consistent measurements. Granite is also non-magnetic and non-conductive, avoiding interference with sensitive instruments. Its dense structure resists wear and scratches better than metal, maintaining flatness over time—critical for high-precision tasks where accuracy is paramount.

How do I choose the right size when considering granite surface plate for sale?

When selecting granite surface plate for sale, consider the size of the parts or tools you’ll inspect. A plate should be large enough to accommodate your largest component with room to maneuver measuring tools. For small parts, a benchtop plate may suffice; for large industrial components, opt for floor-mounted plates. Suppliers often offer custom sizes, so match the plate to your specific workflow needs.

Can surface plate be made from materials other than granite, and how do they compare?

Yes, surface plate can be made from cast iron or glass, but granite is preferred for most industrial uses. Cast iron plates are durable but prone to rust and magnetic interference. Glass plates offer good flatness but are fragile and less resistant to impact. Granite balances durability, stability, and non-reactivity, making it the top choice for applications requiring long-term precision and reliability.

How often should a granite inspection table be calibrated to ensure accuracy?

A granite inspection table should be calibrated at least once a year under normal use. For tables in heavy-use industrial settings or harsh environments, calibration every 6 months is recommended. Calibration checks for flatness deviations using precision instruments, ensuring the table meets original specifications. Regular calibration prevents measurement errors that could lead to faulty part inspections.

Are granite surface plate for sale suitable for outdoor use or humid environments?

Granite surface plate for sale is not ideal for outdoor use or extremely humid environments. While granite resists moisture, prolonged exposure to rain, snow, or high humidity can lead to mold growth or staining. Additionally, outdoor temperature fluctuations may affect flatness over time. These plates perform best indoors in climate-controlled spaces, where environmental conditions remain stable—ensuring their precision and longevity.

Don’t compromise on precision—choose the reliability of our granite products. Contact us today to schedule a visit and experience the quality that makes us a trusted partner in precision measurement. Your success in quality control starts with the right tools, and we’re here to deliver.

-

Thread Plug Gauge Requires Careful HandlingKabarJul.29,2025

-

Surface plate calibrationKabarJul.29,2025

-

Ring Gauge Ensures Machining AccuracyKabarJul.29,2025

-

Pad Iron Reinforces Anchor PointsKabarJul.29,2025

-

Ground anchor stabilizes embankmentsKabarJul.29,2025

-

Granite Box Maintains Precision FlatnessKabarJul.29,2025

PRODUK sing gegandhengan